- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

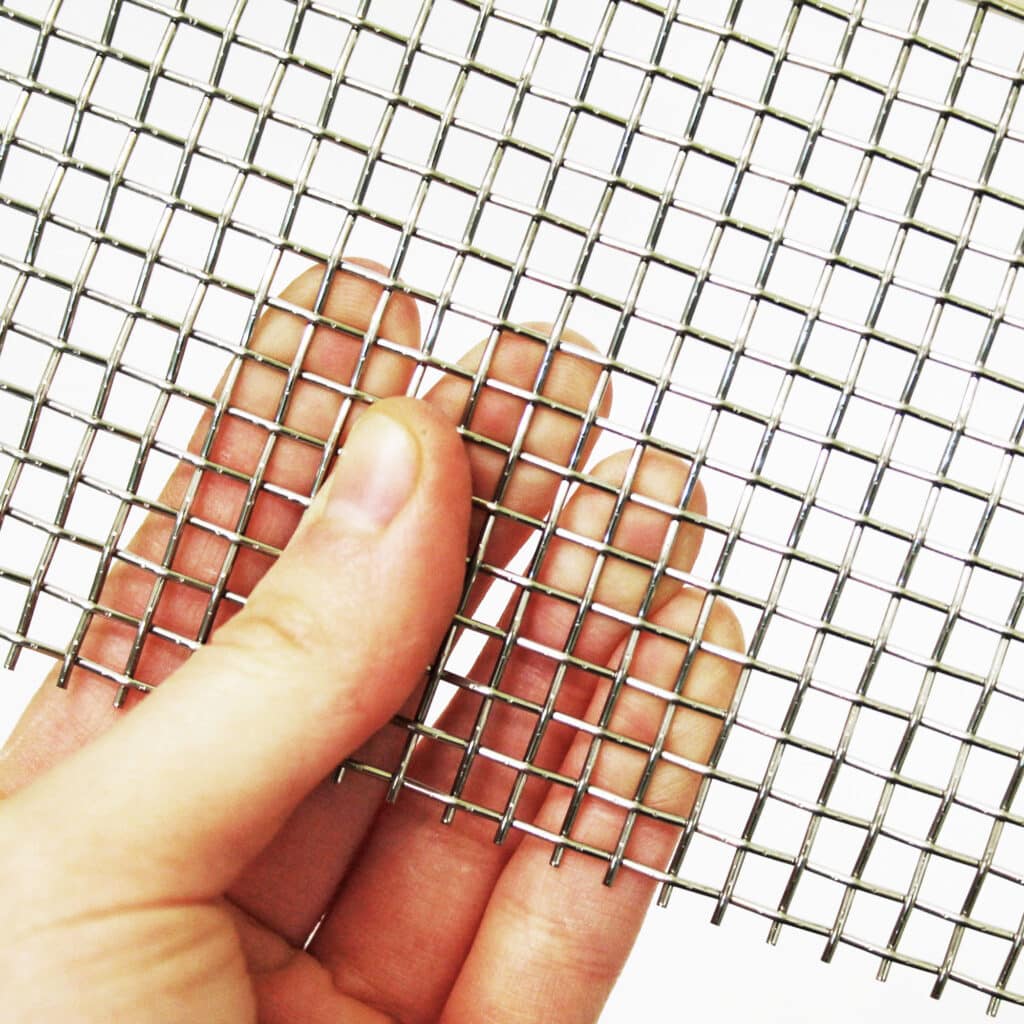

Home » 304 Grade Stainless Steel Woven Wire Mesh: Overview and Benefits

304 grade stainless steel woven wire is a type of mesh that offers a variety of advantages for industrial, commercial, and residential applications. This type of stainless steel is more durable than other types and resists corrosion while being easy to maintain. Let’s take a closer look at some of the features and benefits offered by this popular material.

304 grade stainless steel is an alloy made up of chromium (18-20%), nickel (8-10%), and molybdenum (2-3%). This combination allows the material to be resistant to corrosion, making it ideal for use in outdoor settings or areas with high levels of humidity. It also has excellent strength properties, which makes it the perfect choice for applications that require durability. In addition, this type of stainless steel has low maintenance needs and can retain its shine over time with minimal effort required from the user to keep it looking its best.

As part of our partnership with The Mesh Company we are also able to offer brass, copper, galvanised steel and blue PVC wire mesh products at amazing prices.

Here is a general overview of the weaving process:

The primary benefit offered by 304 grade stainless steel woven wire mesh is its resistance to corrosion. This makes it suitable for use in outdoor settings where the material will be exposed to moisture or salt water. Additionally, this type of stainless steel does not rust or corrode easily, so you don’t have to worry about it becoming discolored or damaged if exposed to certain elements. It also offers superior strength compared to other materials like aluminium or plastic, which makes it an ideal choice for applications that require durability. Finally, since this type of material is non-magnetic, it can be used in areas with magnetic fields without fear of interference.

304 stainless steel mesh is popularly used in filtration systems for either liquid or air filtration. You might find these meshes in water filters, oil filters, and even industrial gas filters. In addition, these meshes are often used as strainers and sieves for filtering out particles from liquids and other substances. With its durable construction, 304 stainless steel provides an effective barrier for preventing unwanted particles from entering a system.

This type of mesh also has widespread use in industrial settings as well. It can be used as reinforcement when welding metal parts together or as a protective wall against sparks produced by welding operations. Additionally, you might find this mesh being used as protective screens on machinery to keep workers safe while they operate them. By providing protection against heat and sparks while still allowing workers to view the machine’s components without obstruction, 304 stainless steel woven wire mesh is invaluable in many industrial settings.

304 stainless steel woven wire mesh isn’t just useful in industrial settings; it also has plenty of architectural applications too! This type of mesh is popularly used for structural reinforcement due to its strength and durability; it can easily be applied to concrete structures such as bridges and buildings where added strength may be required. Additionally, if you’re looking for something decorative yet secure, these meshes make great security screens on windows or doors due to their ability to allow light through while keeping intruders out.

As you can see, there are countless different uses for 304 stainless steel woven wire mesh! Thanks to its strength and durability, this material is perfect for both industrial and architectural applications alike. Whether you need something that will keep your home safe or reinforce components during your welding projects, 304 stainless steel woven wire mesh is sure to have an application that meets your needs!

304 grade stainless steel woven wire mesh is an excellent choice for any project that requires a durable yet corrosion-resistant material. Its low maintenance needs make it a great option for those who are looking for a product that won’t require constant upkeep and can retain its shine over time with minimal effort from the user. From outdoor applications where exposure to moisture or salt water could damage other materials to areas requiring strength and protection from magnetic fields, 304 grade stainless steel woven wire mesh has many advantages that make it an ideal option for any project.

Well that about covers the main questions. We also try to answer all the questions that you may have through the product pages themselves. Look out for the FAQs section on each page.

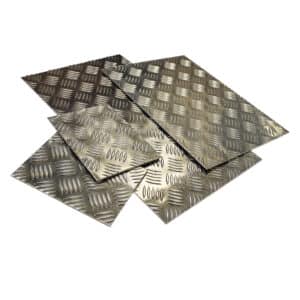

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently. These articles may also help to assist you to make the right decision when selecting which metal works best for you.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options