- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » What You Can Do with a 6mm Mild Steel Sheet Metal: Applications, Machining, and More

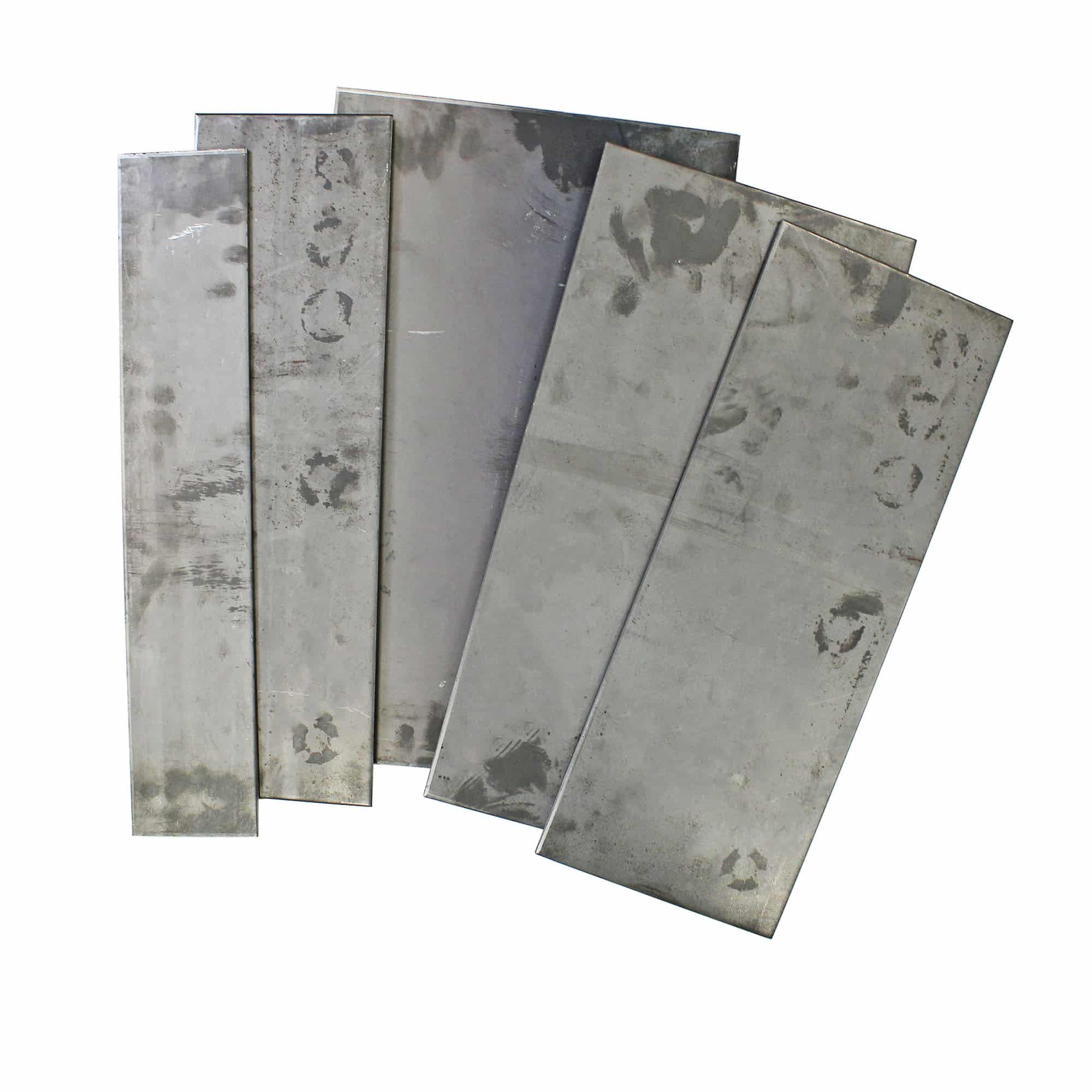

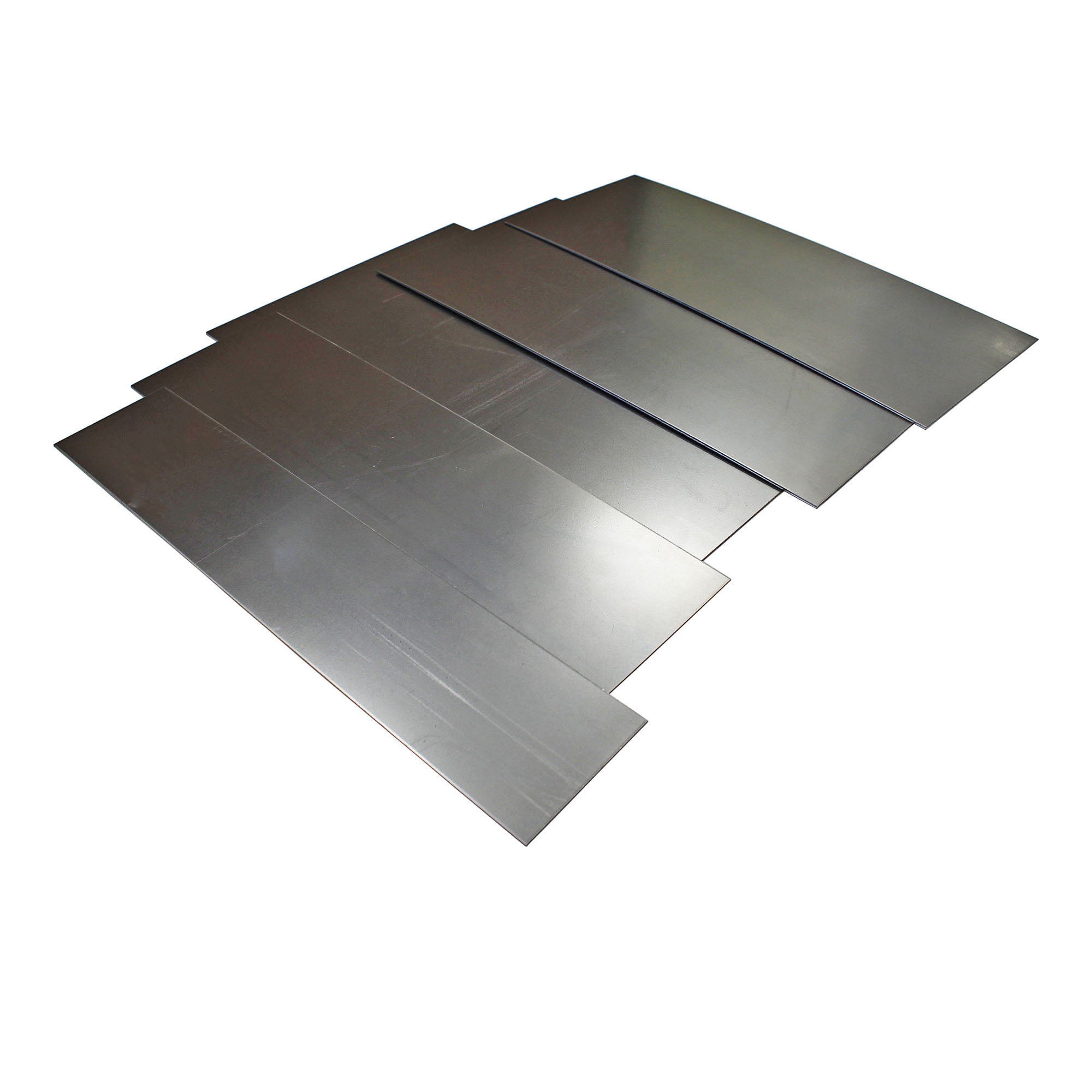

At Speciality Metals, we know that when it comes to choosing the right material for construction, fabrication, or DIY projects, 6mm mild steel sheet metal is a top choice for its exceptional balance of strength and workability. This medium-thickness steel sheet offers the durability needed for load-bearing or structural applications, while still being flexible enough to work with standard machining tools. From industrial projects to creative home improvements, 6mm mild steel sheets are as versatile as they are reliable.

In this guide, we’ll cover everything you need to know about 6mm mild steel sheet metal. We’ll start by diving into its unique properties, including strength, durability, and machinability, so you can understand why this material is so valued across various sectors. Then, we’ll explore common applications where this thickness truly shines, along with a breakdown of the best machining methods for clean and precise results. For those considering corrosion protection, we’ll also touch on surface treatments that can extend the lifespan of your mild steel.

Whether you’re a professional fabricator or a DIY enthusiast, Speciality Metals’ high-quality 6mm mild steel sheets are designed to meet the demands of your next project. Read on to discover why our mild steel products are trusted by craftsmen and engineers alike.

Material Composition and Characteristics:

Mild steel, also known as low-carbon steel, typically contains around 0.05-0.25% carbon, which gives it a unique balance of strength and malleability. The low carbon content makes mild steel less brittle and easier to work with compared to high-carbon steels, which are harder but more prone to cracking. This makes 6mm mild steel an ideal choice for projects that require a sturdy yet adaptable material. At Speciality Metals, we offer 6mm thick mild steel sheets that meet these exact specifications, making them suitable for a broad range of uses, from structural components to precision-crafted parts.

Strength and Durability:

One of the standout qualities of 6mm mild steel is its strength-to-weight ratio. At this thickness, the steel provides substantial rigidity and structural integrity, making it ideal for applications that need to withstand significant loads or stress. This makes it a preferred material in construction projects, automotive manufacturing, and heavy-duty DIY projects. Whether you’re building frames, brackets, or custom fixtures, our 6mm mild steel sheets offer the robustness required to support your design.

Corrosion Resistance and Surface Treatments:

While mild steel is strong, it is not naturally resistant to corrosion, especially when exposed to moisture or harsh environmental conditions. However, there are several surface treatments you can apply to protect it. Galvanization, where the steel is coated with a layer of zinc, is a popular choice for outdoor applications. Alternatively, painting and powder coating can also provide a protective barrier, along with an aesthetic finish. At Speciality Metals, we recommend these treatments to enhance the longevity of our mild steel sheets, especially if they’ll be used outdoors or in humid environments.

Ease of Machining:

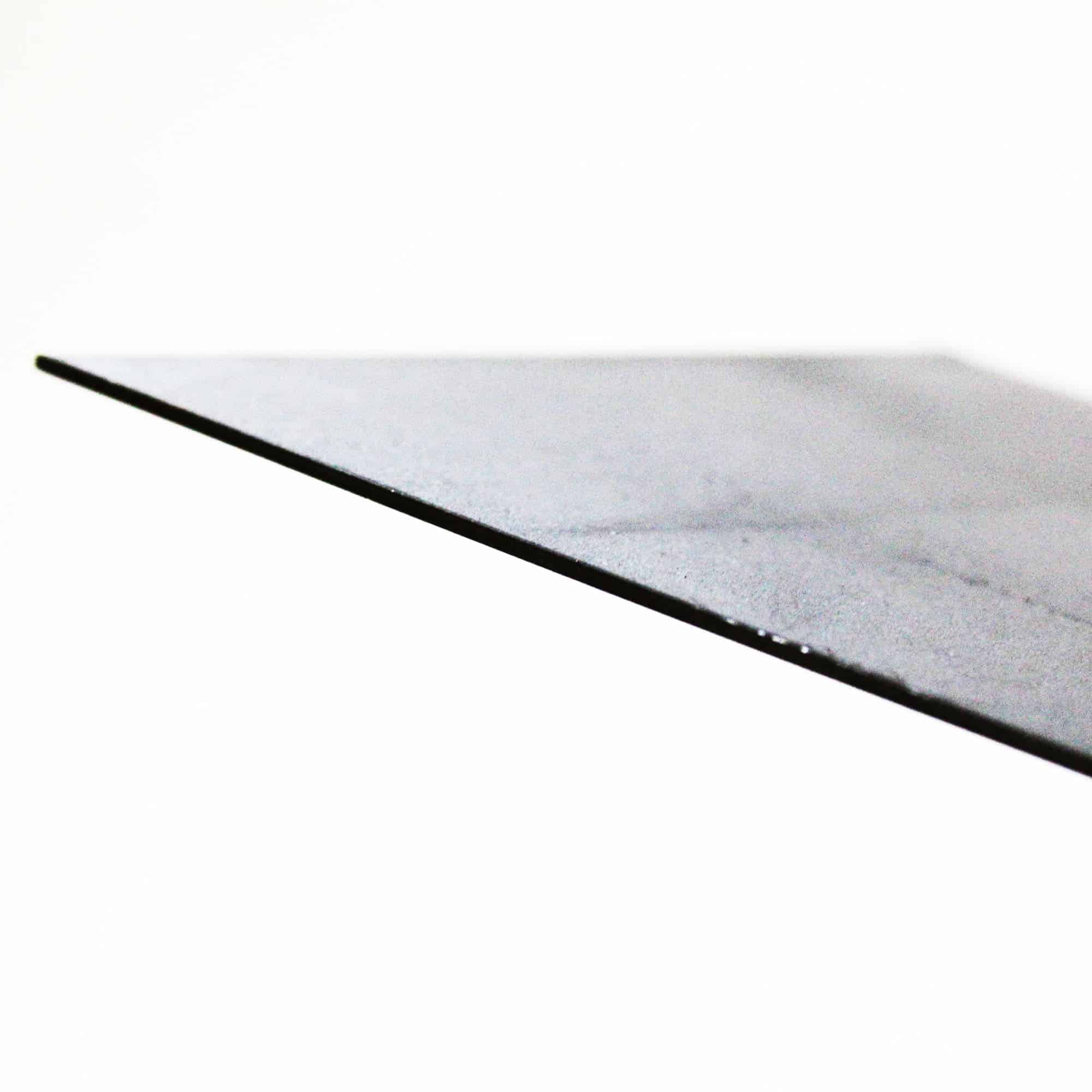

Another reason why 6mm mild steel is so popular is its machinability. Mild steel is relatively soft compared to harder steels, which means it can be cut, drilled, and shaped without causing excessive wear on tools. This makes it a favourite among metalworkers, as it allows for precise machining while maintaining structural integrity. With the right tools, our 6mm mild steel sheets can be easily manipulated to meet the specific requirements of your project.

The versatility of 6mm mild steel sheet metal makes it an excellent choice across a variety of industries and applications. Its combination of strength, durability, and machinability allows it to be adapted for both heavy-duty industrial uses and creative DIY projects. Let’s explore some of the most common applications where 6mm thick mild steel truly shines and why it’s the perfect choice for these uses.

In the construction industry, 6mm mild steel sheets are often used for structural reinforcements and brackets that require both strength and stability. At this thickness, the steel is robust enough to serve as a load-bearing element in buildings and other structures. It can also be used for support plates, which provide additional reinforcement where beams or columns meet. The 6mm thickness offers an ideal combination of strength and manageable weight, making it easier to install and handle on-site compared to thicker steel plates.

Example: For metal framing or scaffolding, 6mm mild steel plates provide the necessary support to ensure structural integrity without adding excessive weight to the construction.

In automotive applications, 6mm mild steel is frequently used for fabricating custom parts, protective panels, and undercarriage guards. This thickness provides excellent impact resistance, which is essential for parts that need to withstand road debris and other hazards. Additionally, the 6mm thickness allows for easy fabrication of complex shapes needed for custom panels, reinforcing the bodywork or providing extra protection to the vehicle’s underside.

Example: For an off-road vehicle, a 6mm mild steel undercarriage guard can protect vital components from rocks and obstacles without compromising on manoeuvrability or adding excessive weight.

In industrial settings, machinery often requires durable base plates and guards to ensure safe operation and stability. 6mm mild steel sheets are the perfect material for this purpose, providing a stable base for heavy equipment while also being thick enough to act as a protective barrier. This thickness is also ideal for creating machine casings that shield sensitive components from dust, debris, and accidental impact, maintaining operational safety and extending the machine’s lifespan.

Example: A heavy-duty industrial press might use a 6mm steel base plate to maintain stability during operation, while guards made from the same material protect operators from moving parts.

The agriculture industry often relies on 6mm mild steel for parts that endure rough use and exposure to the elements. Mild steel sheets at this thickness are ideal for creating machinery guards, wear plates, and other protective components. Due to its durability, 6mm steel is suited for use in farm equipment that faces consistent wear, helping extend the life of equipment and reduce maintenance costs.

Example: A 6mm steel plate can be used to reinforce the body of a tractor, providing extra protection in high-wear areas that are frequently exposed to soil, moisture, and heavy impacts.

For DIY enthusiasts, 6mm mild steel sheet metal opens up a world of possibilities in home improvement and custom fabrication projects. This thickness is perfect for building custom furniture bases, heavy-duty shelving brackets, and even outdoor structures such as garden trellises or pergola supports. Its thickness provides the necessary stability without being excessively difficult to work with, making it a popular choice for DIY metalworking projects.

Example: In a custom furniture project, a 6mm mild steel sheet can be used as the base of an industrial-style coffee table, giving it a sturdy foundation while adding a modern, metallic aesthetic.

When it comes to working with 6mm mild steel sheet, the right machining techniques are crucial for achieving clean, accurate results. At this thickness, mild steel offers both strength and a moderate level of workability, making it suitable for a variety of cutting, drilling, bending, and finishing processes.

Below, we cover the most effective techniques for machining 6mm mild steel sheet, along with tips to get the best possible results.

Plasma Cutting Plasma cutting is one of the most efficient methods for cutting 6mm mild steel sheets. Using a plasma torch, this method provides high-speed, precise cuts with minimal risk of warping due to the quick cutting action. Plasma cutting is suitable for straightforward shapes and medium-level precision, making it ideal for industrial and DIY applications alike.

Tip: If you’re cutting multiple sheets or need repetitive shapes, plasma cutting offers the best balance of speed and accuracy.

Laser Cutting Laser cutting is preferred for intricate designs and complex shapes. This method uses a focused laser beam to make clean cuts with high precision. However, laser cutting requires access to professional equipment, which may be costly. It’s ideal for custom projects where detailed patterns are necessary, and its minimal heat-affected zone makes it a great choice for precise applications.

Tip: For projects requiring intricate designs, laser cutting provides clean edges without extensive finishing.

Waterjet Cutting Waterjet cutting uses a high-pressure jet of water mixed with abrasive material to cut through metal. It’s especially useful for 6mm steel because it avoids any heat distortion, preserving the material’s integrity and mechanical properties. Though slower than plasma or laser cutting, it’s ideal for thick steel where maintaining the original structure is critical.

Tip: Consider waterjet cutting for complex shapes or cuts that require a cool, distortion-free process.

Saw Cutting Saw cutting, using either a bandsaw or hacksaw, is a more accessible but slower method. For 6mm mild steel, a bandsaw with a bi-metal blade or a fine-tooth hacksaw can work, though it’s not as precise as plasma or laser cutting. This is a viable option for DIY projects where professional cutting equipment isn’t available, but it requires patience and a steady hand.

Tip: When using a saw, secure the steel firmly in a vice or clamps to ensure accuracy and reduce vibrations.

Drilling: Drilling into 6mm mild steel requires sturdy drill bits that can handle the hardness of the material. Cobalt or high-speed steel (HSS) drill bits are ideal, as they offer durability and heat resistance. Start with a smaller pilot hole to make drilling easier and reduce the risk of damaging the bit. Using a low to medium speed setting is best, as high speeds can generate excessive heat and cause the bit to dull prematurely.

Tip: Apply cutting oil or coolant to reduce friction, extend the life of the drill bit, and achieve a cleaner hole.

Bending and Forming: 6mm mild steel is thick enough to require significant force for bending. Using a press brake or a hydraulic press is recommended to achieve clean, controlled bends. While it’s possible to bend 6mm steel, it requires careful planning, as improper technique can lead to cracking or deformation. For DIYers, you may need to visit a workshop or use professional tools if precise bending is required.

Tip: Always calculate the bend radius before forming 6mm steel to prevent material stress and ensure accurate results.

Welding: Welding is a popular technique for joining 6mm mild steel sheets, and both MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding are suitable. MIG welding is faster and easier, making it ideal for larger projects, while TIG welding offers more precision for cleaner joints. Preheat the steel slightly to reduce stress, and be mindful of the heat input to avoid warping.

Tip: Ensure proper ventilation and use protective gear when welding, as welding mild steel can release fumes.

Grinding and Finishing: After cutting or welding, grinding and finishing provide a professional touch to the edges. Use an angle grinder to smooth rough edges and a deburring tool for finer work. Finishing can also involve polishing or applying a protective coating, such as paint or sealant, to prevent corrosion and improve appearance.

Tip: For a polished finish, start with a coarse grinder and work down to finer sandpaper or polishing pads to get a smooth edge.

When working with 6mm mild steel sheet metal, preparation and the right techniques can make all the difference in achieving clean, accurate results. This section provides essential tips on tool selection, safety, handling, cooling, and storage to help you get the best performance from your 6mm mild steel.

Tool Selection

Choosing the right tools is critical when working with 6mm mild steel. Given the material’s thickness, it requires robust equipment for precise cutting, drilling, and forming. For cutting, metal-cutting saws with carbide-tipped or bi-metal blades are recommended, as they can handle the thickness without dulling quickly. Cobalt or high-speed steel (HSS) drill bits are ideal for drilling, as they offer durability and resist the heat generated by working with steel. For welding, a MIG or TIG welder will provide the strength and control needed for clean joints. If you’re bending 6mm steel, consider using a hydraulic press or a press brake for accuracy and safety.

Safety Gear

Working with metal requires proper safety precautions to protect yourself from injuries. When working with 6mm mild steel sheets, safety goggles are essential to protect your eyes from metal shavings, sparks, and dust. Heavy-duty gloves are necessary to prevent cuts and burns, especially when handling sharp edges or hot surfaces. Ear protection is also important, as cutting and drilling steel can generate high noise levels. Additionally, if you’re welding, a full face shield with proper UV protection is a must to shield your eyes and face from harmful light and sparks.

Handling Techniques

6mm mild steel sheets are relatively heavy and require proper support during machining to avoid any movement that could lead to inaccurate cuts or bends. Ensure the sheet is securely clamped or held in place before starting any work. For larger sheets, it’s helpful to use a workbench with an adjustable clamp or a metalworking vice to keep the sheet stable. When bending, apply force evenly and ensure the sheet is fully supported along the bend line to prevent unwanted warping or distortion. For smaller projects, additional supports or backing can help maintain the material’s shape.

Cooling Techniques

Cutting, drilling, and grinding mild steel generates heat, which can lead to tool wear and warping of the steel if not properly managed. Using cutting fluids or oils during machining can significantly reduce heat buildup. These fluids lubricate the cutting surface and help maintain tool life, ensuring smoother cuts and cleaner holes. For best results, apply cutting fluid directly to the area before and during machining, especially when drilling or sawing. For intense operations, such as prolonged cutting, consider taking short breaks to let the material cool down.

Storage

Mild steel is prone to rust, so proper storage is crucial to maintain its quality. If you’re storing sheets for any length of time, keep them in a dry, indoor environment. Avoid direct contact with concrete floors, as they can draw moisture and accelerate rusting; instead, place the sheets on wood or a protective barrier. If you’re storing mild steel sheets in a potentially humid environment, consider applying a temporary rust-inhibiting coating to protect them from moisture. A simple spray of machine oil or a light coating of protective wax can be effective, but be sure to clean the sheet thoroughly before use.

6mm mild steel sheet metal is versatile, durable, and ideal for a range of practical and creative projects.

Here, we’ve gathered some inspiring ideas for using 6mm mild steel to create functional, robust items for home, garden, and beyond. Each project takes advantage of the strength and resilience of 6mm steel, making it perfect for heavy-duty applications.

One popular use for 6mm mild steel sheets is crafting durable outdoor furniture and structures. The thickness and strength of 6mm steel make it ideal for weather-resistant tables, benches, and decorative trellises for climbing plants. For example, to make a garden bench, you can cut the steel into rectangular shapes for the seat and legs, then weld them together. Add a coat of rust-resistant paint or powder coating for long-lasting outdoor use. The 6mm thickness offers the structural integrity needed to support weight and withstand outdoor elements without warping or bending over time.

For those looking to create heavy-duty shelving or storage solutions, 6mm mild steel sheets are an excellent choice. This thickness can support substantial weight, making it perfect for industrial-style shelves, garage storage racks, or warehouse solutions. To make a steel shelf, cut the sheet to your desired dimensions, then attach steel angle brackets or weld support beams underneath for added strength. The durability of 6mm steel ensures that these shelves can handle tools, equipment, and other heavy items without sagging, providing a stable and lasting storage solution.

Mild steel isn’t just for industrial or outdoor applications—it’s also great for adding an industrial aesthetic to home décor. 6mm mild steel sheets can be used to create unique wall brackets, picture frames, or even a custom kitchen backsplash. For instance, you can cut the steel into smaller decorative pieces, polish or paint them, and mount them on the wall for an industrial look. The thickness of the steel gives a bold, substantial appearance, while its workability allows for easy customisation to fit your space and style.

For automotive enthusiasts, 6mm mild steel sheets can be used for custom vehicle modifications, such as protective undercarriage plates for off-road vehicles or custom panels. These plates help shield the vehicle’s vital components from rocks, debris, and rough terrain. To create an undercarriage guard, cut the sheet to fit the area you want to protect, drill holes for mounting points, and bolt it to the vehicle’s chassis.

The thickness of 6mm steel provides robust protection against impacts, making it ideal for adventurous or rugged applications.

When it comes to using 6mm mild steel sheet, there are a few common questions we often hear from customers at Speciality Metals. Here are the answers to some frequently asked questions that can help guide your projects:

For cutting 6mm mild steel, both plasma and laser cutting are excellent choices, each with its own advantages. Plasma cutting is a fast and efficient option for thicker metals, providing precise cuts with minimal warping. It’s more affordable and can be done on-site if you have the proper equipment. However, plasma cutting may leave a slightly rougher edge compared to laser cutting.

On the other hand, laser cutting offers extremely precise, clean cuts, making it ideal for intricate designs. Laser cutting requires specialised equipment and can be more costly, but it’s preferred for applications that require high accuracy and minimal finishing. If you’re looking for straight cuts or are working on a DIY project, a high-quality metal cutting saw can also work, though it may be less efficient than professional methods.

Generally, bending 6mm mild steel by hand is not feasible due to its thickness and rigidity. Bending steel of this thickness typically requires professional equipment such as a press brake or hydraulic bender. These tools can apply the necessary force to achieve precise angles without damaging the material. For DIY projects, if you only need slight bends, you might be able to use heat to soften the metal, but professional assistance is recommended for accurate and consistent results.

Yes, 6mm mild steel can be used outdoors, but it is prone to corrosion if left untreated. To protect mild steel from rust, it’s essential to apply a protective coating. Options include painting, powder coating, or galvanising. These coatings help create a barrier against moisture and environmental elements, extending the lifespan of the steel. For outdoor applications, galvanising is particularly effective, as it involves coating the steel in a layer of zinc to protect it from rust.

The weight-bearing capacity of 6mm mild steel depends on factors like sheet dimensions, support points, and the type of load (static or dynamic). As a general guideline, 6mm steel can support substantial weight, making it suitable for structural applications like shelving or support brackets. However, if your project involves heavy or load-bearing structures, we recommend consulting with a structural engineer to ensure the steel can handle the specific requirements of your application.

Absolutely, 6mm mild steel is highly suitable for welding. Both MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding methods work well for this thickness. MIG welding is often chosen for its speed and ease of use, while TIG welding provides greater precision and a cleaner finish, particularly for detailed or aesthetic projects.

Mild steel’s low carbon content makes it less prone to cracking during welding, allowing for strong, reliable welds.

Slightly thicker, offering more durability while remaining flexible and easy to work with.

Known for its increased durability while still being lightweight and easy to cut or weld.

This thickness provides substantial strength while still being easy to machine.

Thick and sturdy, 3mm mild steel is a go-to choice for heavy-duty applications.

Thicker sheets like this are used for the most robust applications requiring maximum durability.

This ultra-thin sheet is perfect for lightweight applications where flexibility and precision are key.

This thickness strikes a balance between flexibility and strength, making it ideal for everyday applications.

With a sturdier build, this sheet is suitable for more robust applications requiring moderate strength.

With increased rigidity, this sheet can withstand higher loads and rough handling.

This thickness is designed for demanding applications where strength is critical.

The thickest in our range, 6mm sheets are built for extreme strength and durability.

In summary, 6mm mild steel sheet metal is an incredibly versatile material, prized for its balance of strength, workability, and adaptability across a variety of applications. From DIY home projects to industrial fabrication, the durability and resilience of 6mm mild steel make it an ideal choice for structural reinforcements, custom parts, and even artistic creations. This thickness offers enough strength to handle substantial loads, yet remains manageable enough for a range of machining processes, whether you’re cutting, drilling, welding, or bending.

Working with 6mm mild steel sheet requires attention to detail and the correct machining methods to ensure clean, precise results. Choosing the right tools, using proper cooling techniques, and ensuring careful handling are essential to maintaining the integrity and longevity of your project. With the right approach, 6mm mild steel sheet can be shaped and adapted to meet the demands of even the most complex applications.

At Speciality Metals, we pride ourselves on providing high-quality 6mm mild steel sheet metal, carefully sourced to meet the diverse needs of our customers. We invite you to explore our selection, confident that our products will meet the highest standards of durability and performance.

If you have specific project requirements or questions about working with mild steel, don’t hesitate to reach out.

Our team is committed to supporting you every step of the way, ensuring you have the materials and expertise needed to achieve outstanding results.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about using mild steel sheet for auto body repair and cold rolled vs hot rolled steel recently.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options