- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » What is Perforated Metal Sheet?

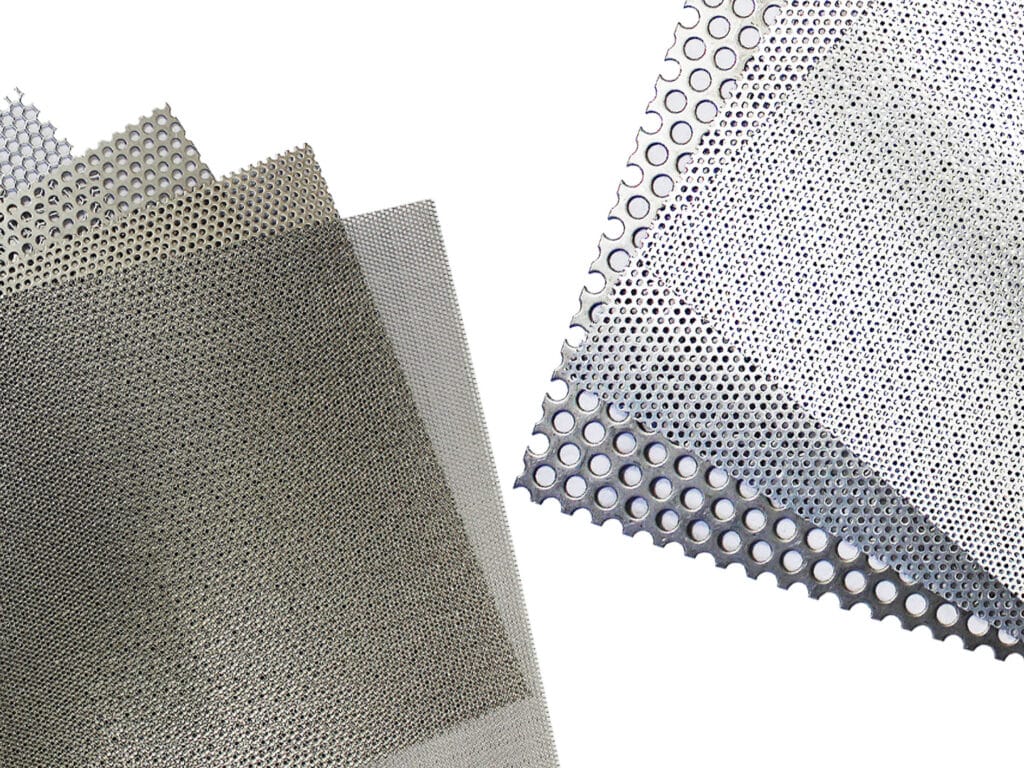

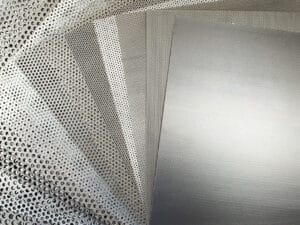

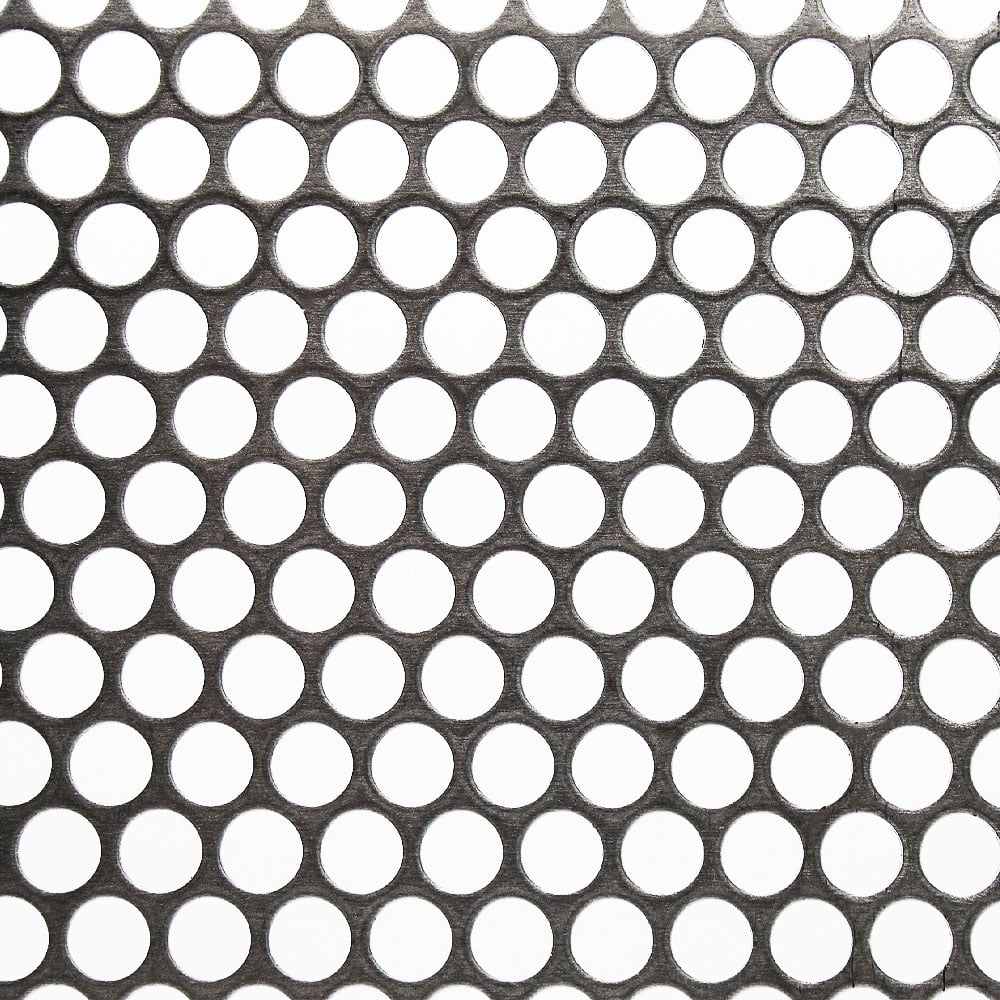

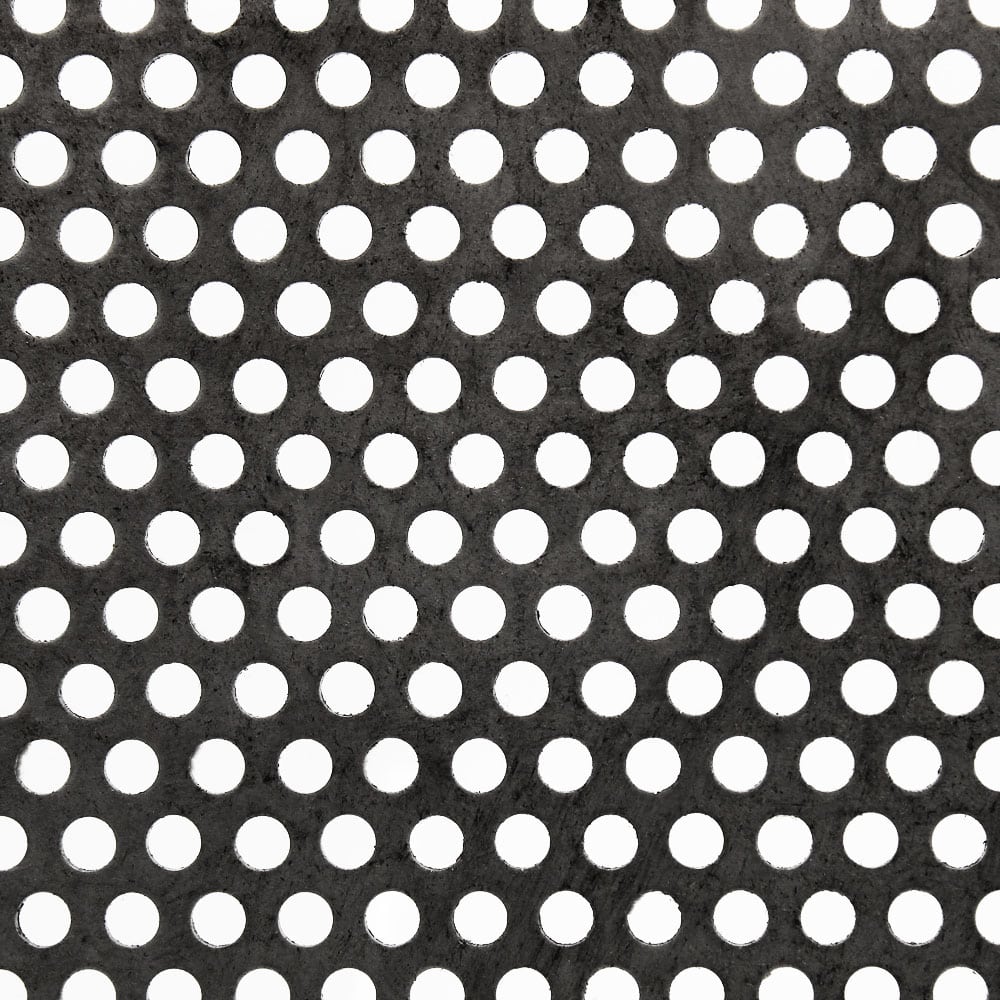

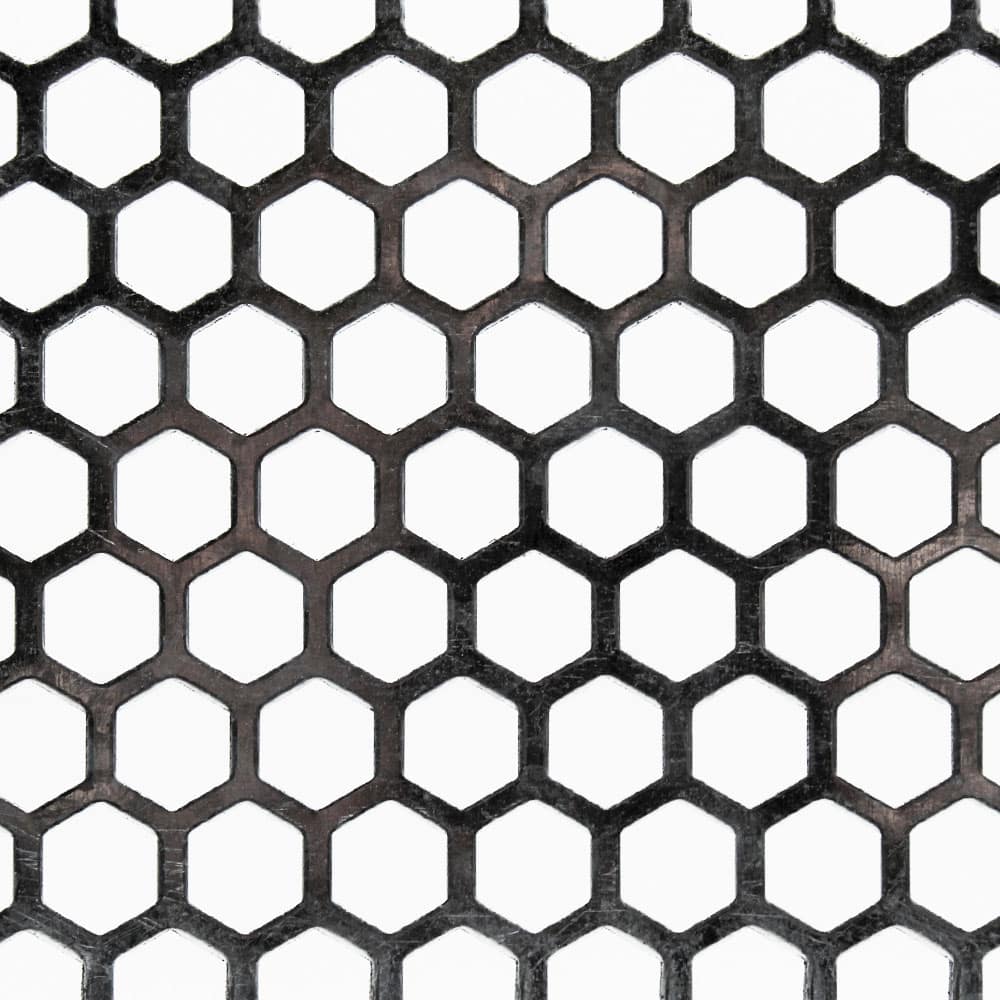

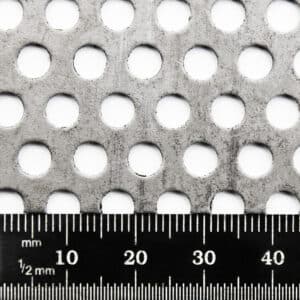

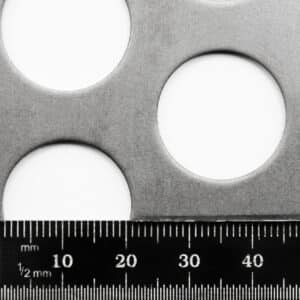

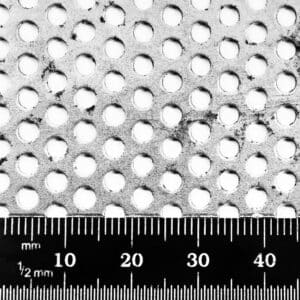

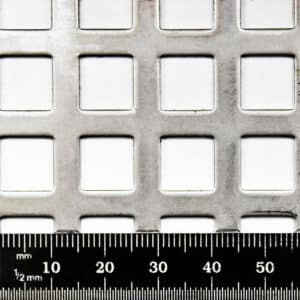

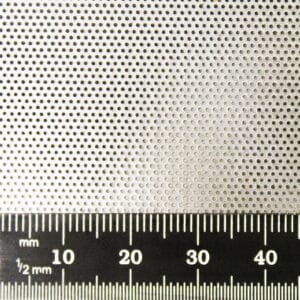

Perforated Metal Sheet is a highly used, strong material often seen in the construction and transport industry. It’s manufactured from a sheet of metal which consists of punching multiple holes in a pattern formation and can come in a variety of hole shapes and sizes.

There are a few ways in which perforated metal can be made. The first way in which it can be made is by taking a flat sheet of metal and feeding it through an industrial rolling machine. The metal sheet then gets punched with needles that puncture out the holes as the rotating cylinders move the sheet along and out the other side.

There is also laser perforation, this consists of a single laser aligned with the metal sheet so that the laser cuts out the holes in the exact places that’s required.

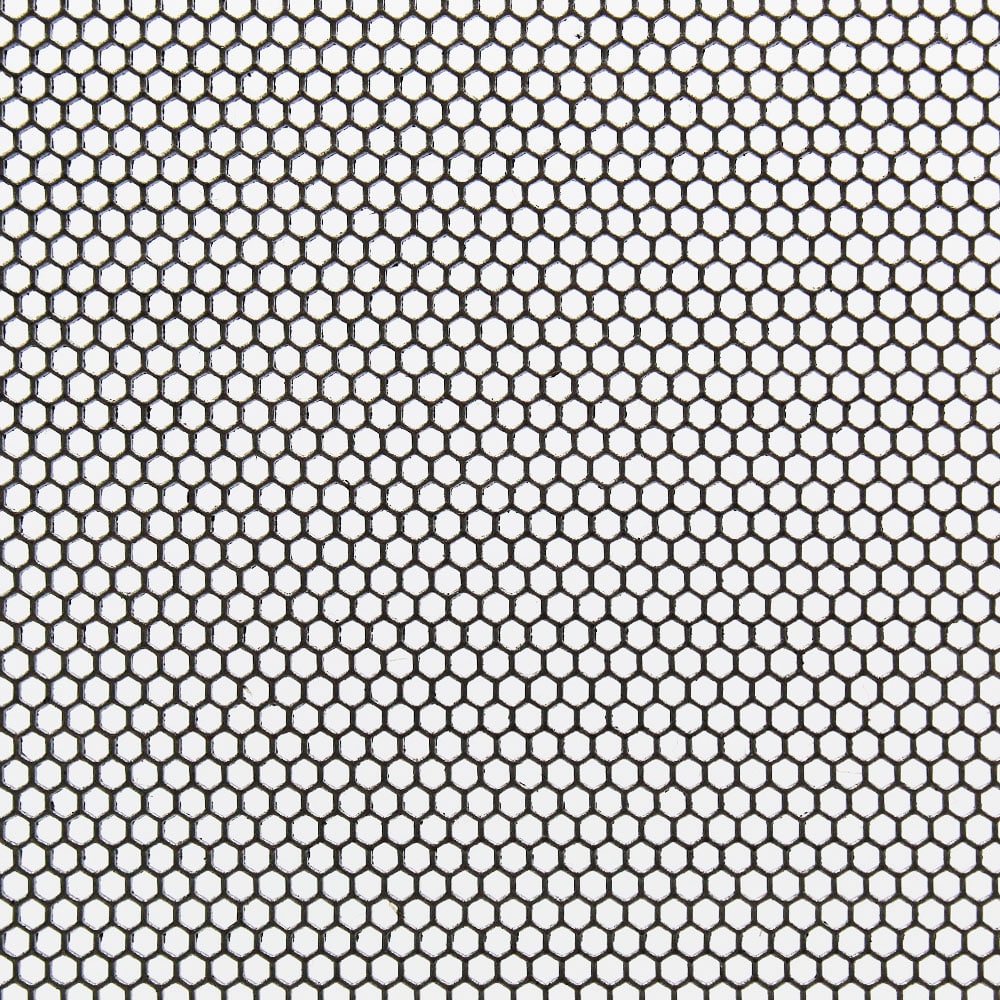

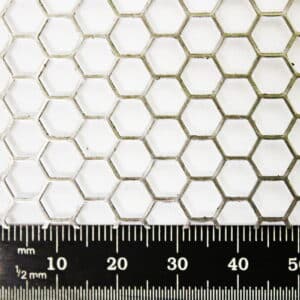

There are a wide range of different sizes and shapes of holes available. The most common shapes are round, square and hexagon shaped holes. The holes can be all the same size or they can be punctured in different sizes on the same sheet, this is often used when creating an image. This application is called ImagePerf which is great for using in architecture or sculpturing.

They also come in different types of metal like aluminium, galvanised steel, mild steel and stainless steel.

ImagePerf is the only application of perforated metal that doesn’t require the holes to be all the same size and shape. Normally perforated steel sheets have holes that are all the same size and shape unless you want to use ImagePerf.

ImagePerf is when the holes sizes are varied and are punched out in a way that’s intended to make an image. Any image is possible and it creates an effective and attractive appearance, it’s an increasingly popular trade in modern architecture.

Due to perforated metal sheet being a strong material and coming in a wide variety of styles, this makes it a very popular and useful building appliance. Ways in which perforated sheet are great for using in are:

Aluminium is one of the metal alloys that is great for using to make perforated metal sheets. It’s an ideal material for sheet metal because it’s strong, lightweight, resistant to corrosion, heat and chemical resistant.

Aluminium is weatherproof and doesn’t react with many elements so it’s perfect for using outdoors and it won’t rust. It also has a reflective surface which can give it an attractive appearance.

We supply 1050 grade aluminium as we believe it’s the most versatile and beneficial form of aluminium compared to the other grades. This is because it has the highest melting point so it is a good resistor of heat and it also consists of all the other advantages of aluminium.

Plain mild steel is a solid metal with no other combining alloys and is just pure steel apart from a small amount of carbon to make it stronger.

Because mild steel has no added alloys apart from carbon to strengthen it, it can be an extremely versatile building component. It’s also not resistant to corrosion and will rust over time. Mild steel is also a heavy material which can make it difficult to work with however it’s a cost effective metal, it has great welding abilities and you can paint over it.

Galvanised Steel is another great metal to use as perforated metal because it has a protective coating which makes it corrosion resistant and ideal for outdoor use.

It’s essentially plain mild steel that has been hot dipped in a zinc coating which adds a layer of protection from corrosion and reacting to the environment. Galvanised steel is also great for welding and it’s economical as you can get long lasting use due to its protective coating.

Stainless steel is the most prevalent and functional metal and perfect for using as perforated sheet metal. It is strong and has good resistance to heat and corrosion. It’s also good for welding and it’s great for outdoor use as it’s weatherproof and won’t react to outside elements.

Despite it a more expensive metal, you will also get more use out of it because its long lasting and it will retain its attractive appearance.

Our perforated metal sheets get cut down with an ultra-powerful industrial guillotine. It simply gets fed into the cutting line and positioned where it will cut off the required length. It is then held into place and a single blade lowers down to cut the sheet into two pieces with the press of a button.

Having our guillotine means we can cut down our sheets to any size required.

All our sheets start from 500mm x 1000mm (1 Metre) size panels. They then get cut down on our guillotine to the required size.

Our cutting service is rapid, fuss-free and to accommodate to any request no matter how big or small.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options