- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » The Ultimate Guide to Aluminium 5 Bar Checker Plates

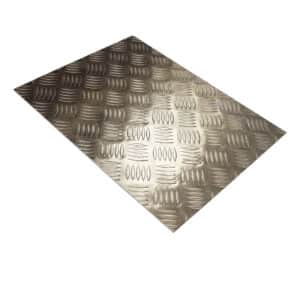

Aluminium checker plates, with their distinct design and remarkable durability, have become an indispensable material in various industries. Often known are kick plate, or tread, you will be likely to be more familiar with this type of metal than any other.

Among the different types of pattern, the 5 bar checker plate stands out for its unique pattern and specific advantages.

In this comprehensive guide, we’ll delve deep into the world of 5 bar aluminium checker plates, exploring their features, applications, and benefits.

Let’s get into it…

At the outset, it’s essential to understand what checker plates are.

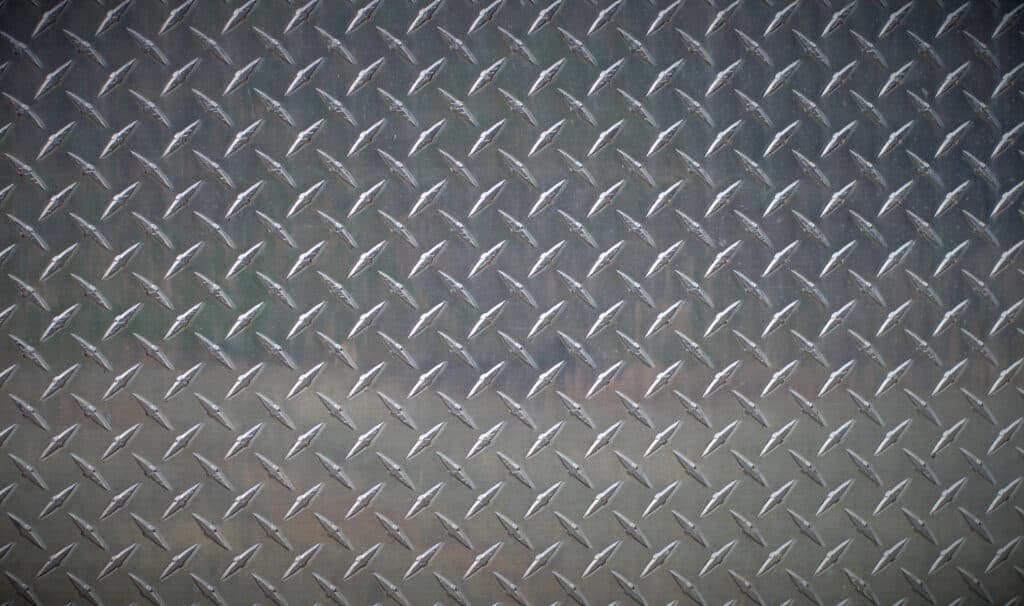

Aluminium checker plates, often known as tread plates or diamond plates, feature raised patterns on one side, providing both functional and aesthetic benefits.

The raised pattern ensures slip-resistance, while the shiny aluminum finish offers an appealing look. This is why this sheet metal is so ubiquitous.

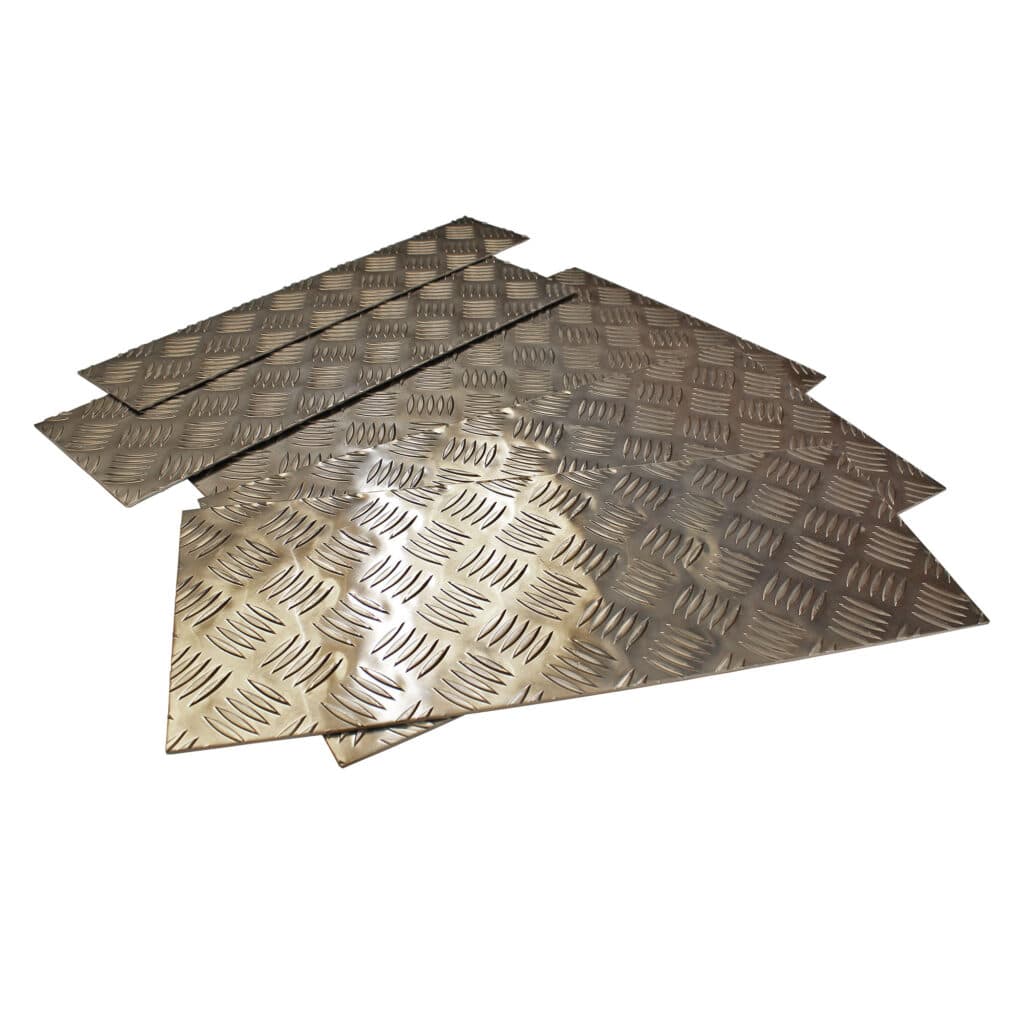

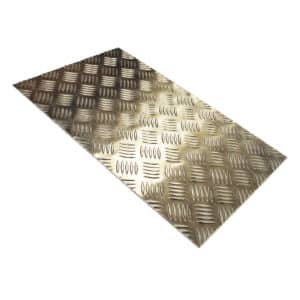

The 5 bar checker plate is named for the five parallel bars that constitute its pattern.

Unlike other patterns like diamond or 2 bar, the 5 bar design offers a distinct appearance coupled with excellent anti-slip properties.

To appreciate the value of the 5 bar checker plate, it’s essential to dive into its manufacturing process.

This process not only ensures the material’s strength and durability but also its distinct appearance.

Raw Material Selection: It all begins with high-quality aluminium. As a result of its excellent corrosion resistance and workability, aluminum alloys selected by manufacturers are usually those of the 3000 series.

Hot Rolling: Hot rolling is the process of heating the aluminium and passing it through large rollers in order to roll it into a cylindrical shape. It is through this process that the aluminium becomes thicker, preparing it for the next steps of the process.

Cold Rolling: To achieve the desired thickness and enhance the material’s strength, the aluminium undergoes cold rolling. By rolling the aluminium at room temperature, it can be made thinner and longer by making it longer and thinner.

Pattern Pressing: This is where the signature 5 bar design comes into play. Using specific machinery, the pattern is pressed onto one side of the aluminium sheet. The pressing not only imprints the design but also strengthens the aluminium by creating tension in its structure.

Cutting and Finishing: Once the pattern is set, the plates are cut to the desired size. Any imperfections are addressed, and the edges are smoothed. To enhance the longevity of the plate, some manufacturers offer a protective finish or coating.

In addition to its aesthetic appeal, the 5 bar checker plate is meticulously manufactured. The durability and functionality of this product are assured at every stage, from the selection of raw materials to the pattern pressing process.

Depending on the application and requirement, 5 bar checker plates come in various thicknesses.

The two common ones are 1.5mm and 3mm.

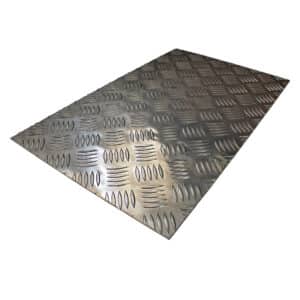

The versatility of the 5 bar checker plate is evident in its wide range of applications:

To maintain the aesthetic and functional qualities of the 5 bar checker plate, regular cleaning and maintenance are crucial.

Here’s a simple guide:

For the 5 Bar Aluminum Checker Plate to remain functional as well as aesthetic, it must be properly maintained. Because checker plates are commonly used in environments prone to wear, such as industrial floors and vehicle platforms, they maintain their slip-resistant properties when well-maintained. As a result of consistent maintenance, corrosion and damage can be prevented, thereby extending the lifespan of the material. Upkeep is therefore a small investment that yields significant returns in terms of safety, functionality, and longevity.

In today’s age, sustainability and environmental consciousness are more than just buzzwords; they’re imperatives.

Fortunately, the aluminium 5 bar checker plate scores high on the green scale.

Recyclability: The recyclability of aluminium makes it unique. The material can be recycled repeatedly without losing its quality or properties. By reprocessing old checker plates, raw materials and energy can be saved.

Energy Efficiency in Production: There is not much of a difference between the energy required to recycle aluminium and the energy needed to produce new aluminium when it is recycled. As a result of prioritising recycled aluminum, the aluminum industry is able to reduce its carbon footprint significantly.

Durability Equals Less Waste: The long lifespan of the 5 bar checker plates means less frequent replacements. In addition to saving resources, this durability also reduces the amount of waste that is generated.

Lightweight Nature: As aluminium checker plates are lightweight, they contribute to the efficiency of the energy system, especially in transport applications. The lighter the vehicle, the less fuel it consumes and the fewer emissions it produces.

Safe and Non-Toxic: There are no toxic substances emitted by aluminium, and it is non-reactive as well. In spite of the fact that it is used in a variety of applications, it does not harm the environment or the users in any way.

End-of-Life Considerations: As soon as an aluminium checker plate has reached the end of its useful life, it does not end up as waste in the landfill. As an alternative, it can be fully recycled, which means that it will have minimal impact on landfills.

Industries and individuals who choose aluminium 5 bar checker plates do so not only for its durability and functionality, but also for its environmental friendliness. A checker plate is a sustainable product, from its production cycle to its end-of-life considerations.

The 5 bar aluminium checker plate, with its unique pattern and myriad benefits, is truly a material for the modern age.

Whether you’re an architect seeking a stylish façade, an industrial worker prioritising safety, or simply someone renovating their garage, the 5 bar checker plate offers both function and form.

As with any material, ensuring its proper maintenance will ensure its longevity, allowing you to enjoy its benefits for years to come.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options