- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

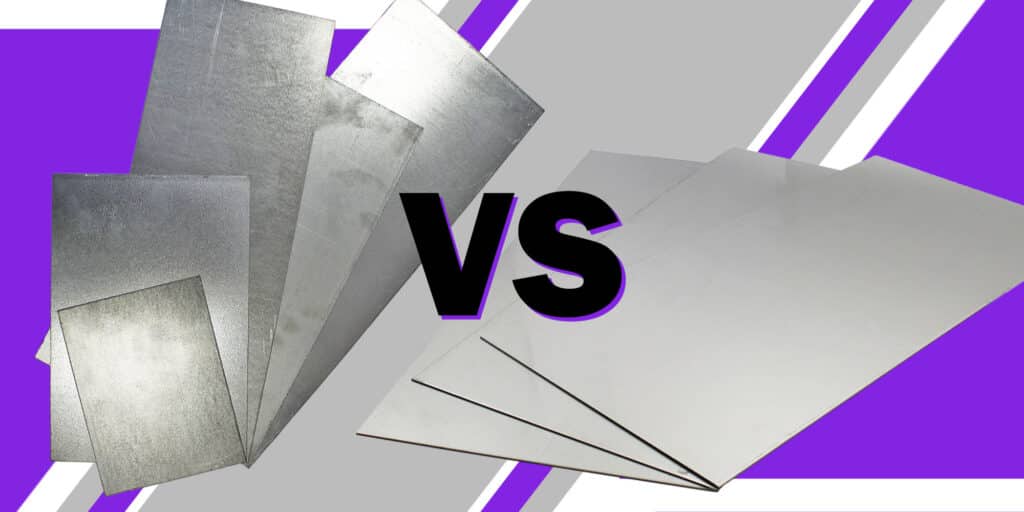

Home » Stainless vs Galvanised Steel: Longevity and Maintenance

When selecting the right materials for any construction or manufacturing project, the choice often comes down to comparing different types of metals based on factors such as cost, durability, and maintenance. Metals such as stainless steel and galvanised steel are the two most commonly used across industries. This article examines the differences between stainless steel and galvanised steel, specifically their maintenance requirements and longevity.

What is Stainless Steel?

Stainless steel is an alloy that is renowned for its rust resistance which comes from its chromium content. The minimum chromium content in stainless steel is 10.5%, which reacts with oxygen in the air to form a protective chromium oxide layer. This layer prevents further corrosion and makes the steel “stainless.” There are multiple grades of stainless steel, each tailored to various environments and applications.

What is Galvanised Steel?

Galvanised steel, on the other hand, is regular steel sheets that have been coated in zinc to prevent rusting. The zinc provides a protective layer that not only shields the steel from the environment but also sacrifices itself because of its more reactive nature compared to steel. This process is known as galvanic protection. Galvanising can be done through several methods, the most common being hot-dip galvanising.

The longevity of metal materials plays a crucial role in applications where long-term reliability is essential. Both stainless and galvanised steel offer excellent longevity, but their performance significantly depends on the environmental conditions they are exposed to.

Stainless Steel

Stainless steel’s chromium oxide layer provides a continuous shield against corrosion that can sustain the integrity of the steel for decades. It performs exceptionally well in environments that are dry and where chloride levels are low. Higher-grade stainless steels are developed to handle more corrosive environments, such as coastal areas where salt spray is prevalent.

Galvanised Steel

Galvanised steel performs best when the environmental exposure to corrosives is low to moderate. Over time, the zinc layer will gradually corrode. The rate at which this happens depends on the conditions of exposure such as moisture and airborne salinity. However, once the zinc layer is depleted, the underlying steel will begin to rust. In harsh environments, this can happen faster than expected.

Maintenance is a critical aspect when considering the total lifecycle cost of materials. Both types of steel have distinct maintenance needs based on their corrosion resistance capabilities.

Stainless Steel

One of the most significant advantages of stainless steel is its minimal maintenance requirement. The non-porous chromium oxide layer not only protects against corrosion but also resists staining and can be easily cleaned with mild detergents and water. For tougher stains, more specific cleaning agents designed for stainless steel can be used without damaging the surface.

Galvanised Steel

While galvanised steel is also low maintenance, the key is to monitor the zinc layer’s condition. Once areas of the base steel are exposed, rust can form unless those areas are treated or re-coated. Maintenance for galvanised steel might involve periodic painting or applying anti-corrosion sprays to enhance its lifespan.

Choosing Between Stainless vs Galvanised Steel

The choice between stainless vs galvanised steel often boils down to the specific requirements of the project and environmental exposure. Stainless steel, with its superior corrosion resistance, is preferred for medical facilities, food processing plants, and marine applications. Galvanised steel is typically used in outdoor construction like roofing, fencing, and railings where cost-effectiveness is prioritised but direct exposure to harsh elements is limited.

Cost is often a decisive factor in material selection. Generally, galvanised steel is less expensive than stainless steel upfront. However, considering the potential for longer life and less frequent need for replacement or maintenance, stainless steel may offer a better long-term value, especially in corrosive environments.

Here’s a table outlining the pros and cons of stainless steel vs galvanised steel:

| Aspect | Stainless Steel | Galvanised Steel |

|---|---|---|

| Corrosion Resistance | Excellent corrosion resistance due to the chromium oxide layer that prevents rust. | Good initial resistance due to zinc coating but deteriorates once the coating is penetrated. |

| Longevity | Very long-lasting, especially in non-corrosive environments or with higher grade alloys. | Generally long-lasting, but lifespan decreases faster in harsh environments. |

| Maintenance | Low maintenance; easy to clean and resistant to staining. | Requires periodic inspection and maintenance to repair exposed areas to prevent rust. |

| Cost | Typically more expensive initially but may be more cost-effective over time due to less maintenance. | Less expensive upfront but may incur additional costs for maintenance and replacement. |

| Appearance | Maintains a clean and shiny appearance, suitable for visible or decorative applications. | Zinc coating can become dull or develop a patina, which may not be desirable for all applications. |

| Environmental Suitability | Better suited for harsh environments, including coastal or highly polluted areas. | Better suited for less corrosive environments unless regularly maintained. |

| Durability | Very durable against physical and environmental factors. | Zinc coating provides durability but can be compromised by scratches or heavy wear. |

Food Processing and Catering Equipment: Stainless steel is often used in kitchen environments and food processing plants because it does not rust and is easy to clean, which helps in maintaining hygiene.

Medical Instruments and Facilities: Due to its non-reactive qualities, stainless steel is ideal for surgical instruments, medical equipment, and in the construction of hospital facilities.

Architecture and Construction: Stainless steel is used in the construction of modern buildings for elements such as facades, handrails, and support beams because of its aesthetic appeal and structural integrity.

Automotive and Aerospace Parts: The high-strength and corrosion-resistant properties of stainless steel make it suitable for various components in the automotive and aerospace industries.

Marine Environments: Its resistance to corrosion by saltwater makes stainless steel ideal for marine hardware, boat fittings, and other applications in marine engineering.

Chemical and Petrochemical Industries: Stainless steel can withstand harsh chemicals and high temperatures, making it suitable for pipes, tanks, and other equipment used in these industries.

Outdoor Construction: Galvanised steel is commonly used in outdoor construction for items like roofing, fencing, and railings where durability and resistance to weather are important.

Automotive Body Parts: Components of vehicles that require corrosion resistance but not the high aesthetic and sanitary standards of stainless steel, like undercarriage parts and body panels, are often made from galvanised steel.

Utility Infrastructure: It is used for guardrails, signposts, and electrical poles due to its strength and weather resistance.

Agricultural Equipment: Farming implements and structures that benefit from corrosion resistance, such as animal feed troughs and water tanks, are often made from galvanised steel.

Home Appliances: Many home appliances, including washers, dryers, and air conditioning systems, utilize galvanised steel for panels and structural components.

Industrial Containers: Galvanised steel is used to fabricate metal containers for storing and transporting goods because it resists rusting.

The decision between stainless and galvanised steel should be guided by factors such as environmental conditions, longevity requirements, and budget. Understanding the specific properties and benefits of each can help in making an informed choice that is both durable and cost-effective. Maintaining your applications costs as low as possible can be achieved by choosing the appropriate steel type.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about the benefits of galvanised steel and maintaining stainless steel recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.