No products in the cart.

Home » Recycle Metal: A Step Toward a Greener Tomorrow

In today’s fast-paced world, the topic of sustainability has shifted from being a mere buzzword to a necessary action. Every industry is looking for ways to contribute to a sustainable future, and metal recycling plays a pivotal role in this journey. “Recycle Metal” is not just a call to action but a commitment to our planet. Here’s a deeper look at how recycling metal is a significant stride toward a greener tomorrow.

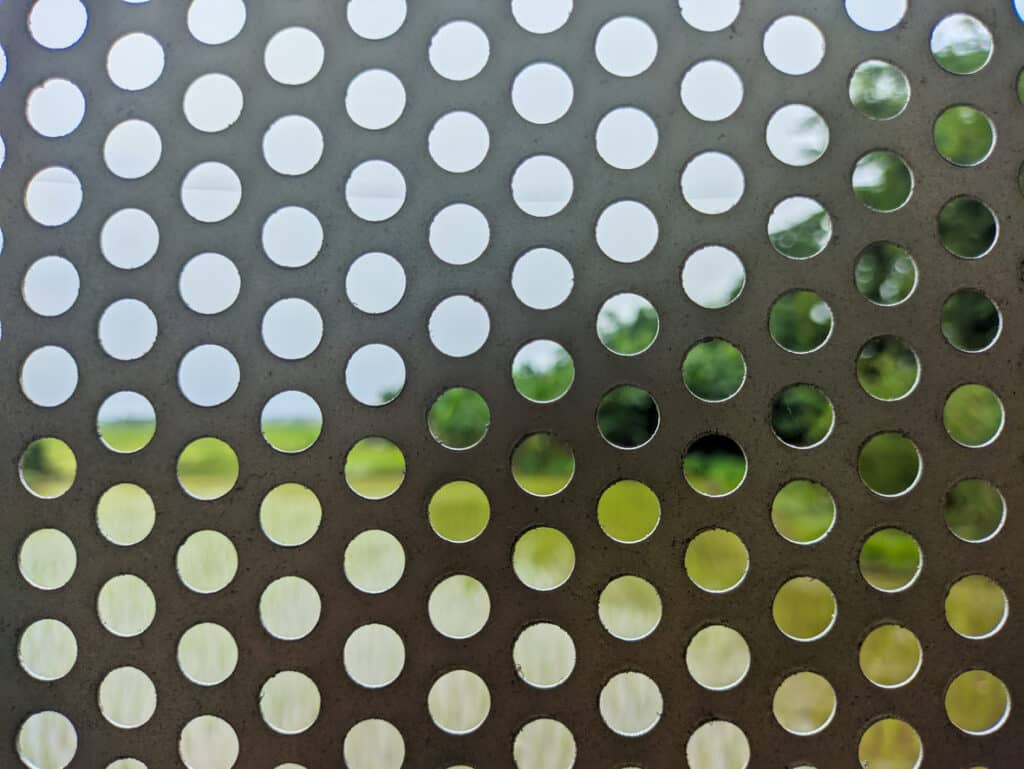

Metals are among the most valuable resources on Earth. They serve as the backbone for infrastructure, transportation, electronics and countless other sectors. With such widespread usage, the demand for metals is ever-increasing. But with limited natural reserves, the extraction of new metal comes at a steep environmental cost, including habitat destruction, soil erosion and significant energy consumption.

Recycling metals reduces the need for raw material mining. Every ton of recycled metal means less disruption to our natural ecosystems and a reduction in the carbon footprint of metal production.

Conservation of Resources: Recycling one ton of steel conserves 2,500 pounds of iron ore, 1,400 pounds of coal, and 120 pounds of limestone. The numbers speak for themselves – recycling significantly conserves natural resources.

Energy Savings: The energy required to recycle metals is considerably less than the energy to mine and process virgin materials. For instance, recycling aluminum uses 95% less energy than producing it from bauxite ore.

Economic Boost: The metal recycling industry supports jobs, from collection to processing. As demand grows, so does the industry, leading to economic benefits at the local and national levels.

Greenhouse Gas Emission Reduction: The reduction in energy consumption directly leads to fewer greenhouse gas emissions, contributing to the fight against global climate change.

While the benefits are clear, the road to efficient metal recycling is paved with challenges. Issues such as the improper separation of metals, lack of awareness about the value of scrap metal and limited infrastructure in some regions can hinder the process. Overcoming these challenges requires collective action from individuals, communities, industries and policymakers.

As consumers, we can make a difference. Start by:

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about how to stop metal from rusting recently so why not check it out.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options