- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

£20.49 – £64.99Price range: £20.49 through £64.99 inc VAT

This website is secured:

£ MULTIBUY SAVINGS – Order 3 For 10% Off

✔ Specialists In Rapid Shipments Of Any Size

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

@ ☏ Bespoke Cuts & Larger Sheets Available

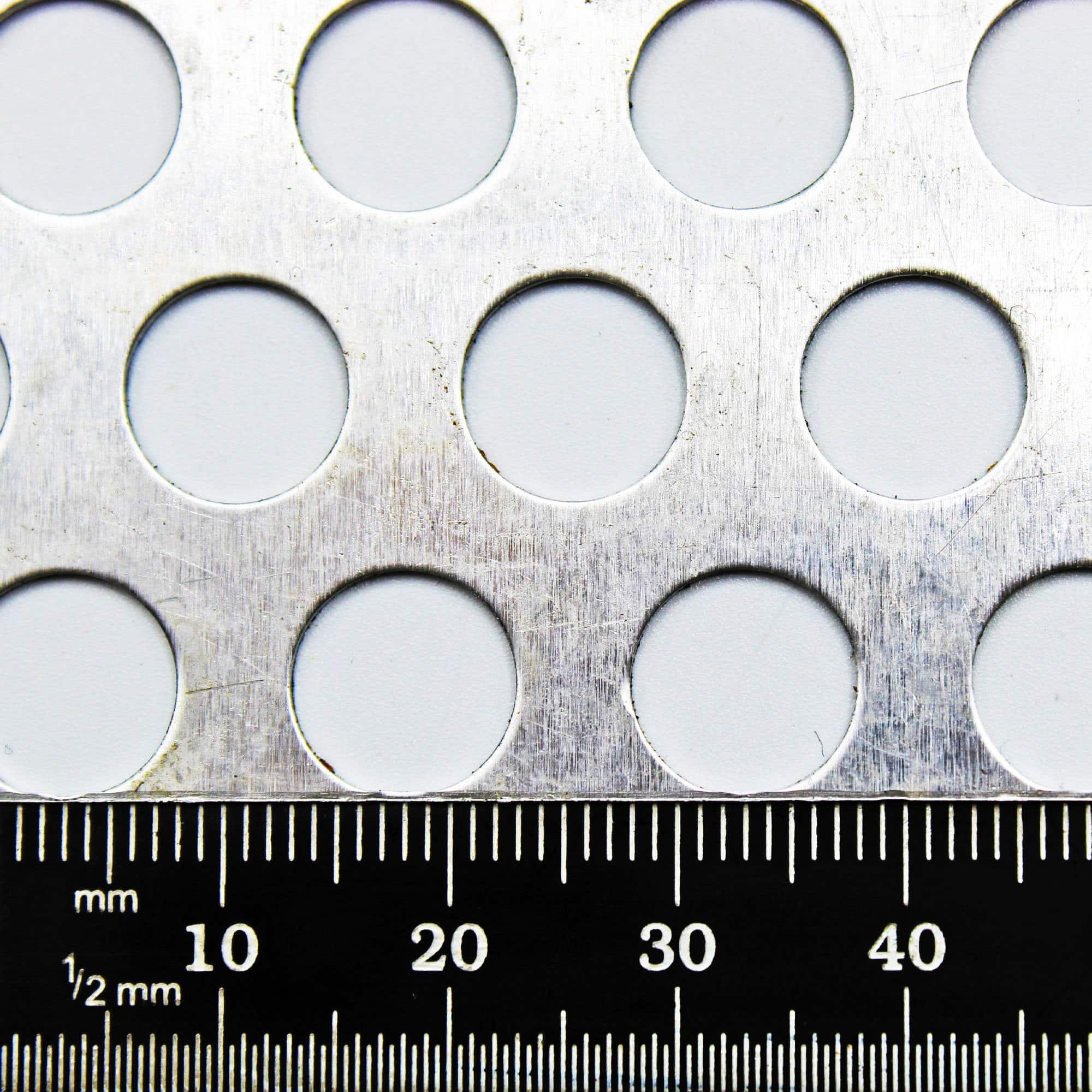

Looking for a truly versatile and cost-effective material for your next project? Look no further than Speciality Metal’s 6mm Hexagonal Perforated Sheet Steel. With a pitch of 6.7mm and a thickness of 1.5mm, this durable and ductile material is perfect for a wide range of applications. Not only does it offer great welding, forming, bending, and machining abilities, but it’s also fully recyclable, making it a sustainable choice for your project. Plus, with its unique hexagonal perforated sheet design, it adds a touch of visual interest to any application. So whether you’re looking to create a striking façade or a functional screen, 6mm Hexagonal Perforated Sheet Steel is the material for you.

Top quality hexagon perforated sheet supplied straight from Warrington, UK.

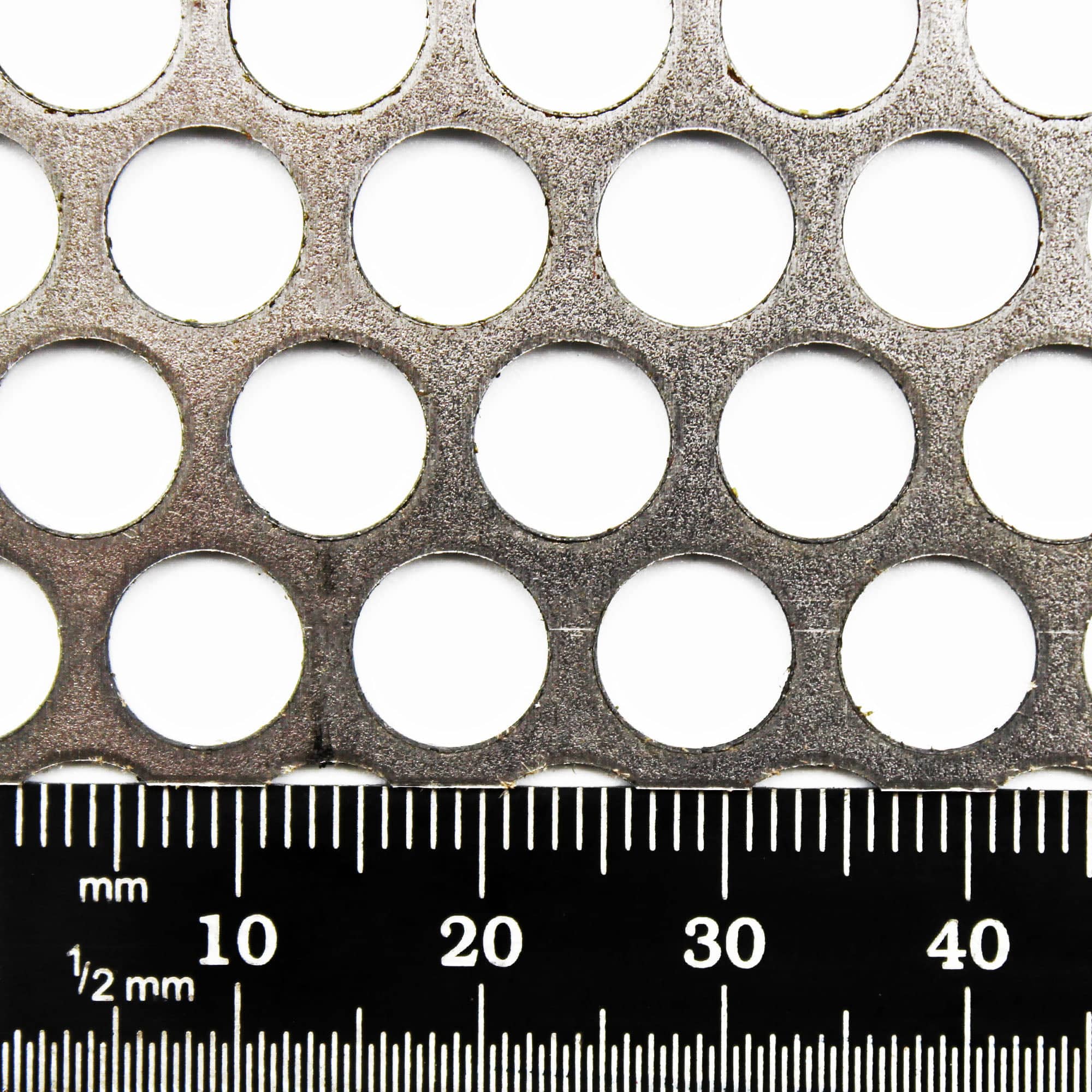

With their 4.5mm Steel Hexagonal Perforated Metal Sheet, Speciality Metals offers a highly versatile and cost-effective solution. This metal sheet offers excellent welding, forming, bending, and machining capabilities, making it a ductile and durable choice for various industrial applications. In addition to providing optimal performance, its hexagonal perforated design adds a unique aesthetic touch to any project. This sheet is also readily recyclable, making it an eco-friendly choice for those looking to reduce their environmental impact. Your next project can benefit from the durability and flexibility of Speciality Metals’ hexagonal perforated metal.

We also are the exact suppliers for you because:

Furthermore we stock a vast range of plain sheet metal options that compliment our mesh range perfectly.

Specifications:

In marine or coastal environments, mild steel perforated mesh can be vulnerable due to the harsh conditions typical of such areas. Here’s an overview of its performance in these environments:

Corrosion: One of the primary concerns with mild steel in marine or coastal settings is corrosion. The salty air and moisture can accelerate the rusting process of carbon steel. Saline environments are particularly aggressive when it comes to corroding metals, and the perforations in the mesh can further increase the surface area exposed to these elements.

Durability: Even with protective coatings, the lifespan of mild steel perforated mesh can be significantly reduced in coastal areas compared to drier, inland climates. Over time, as corrosion advances, the mesh may weaken, compromising its structural integrity.

Maintenance: Regular maintenance is crucial when using mild steel perforated mesh in marine or coastal environments. This might include frequent cleaning to remove salt deposits, regular inspections for signs of corrosion, and periodic re-application of protective coatings.

Protective Coatings: To mitigate the effects of corrosion, mild steel perforated mesh used in marine settings should be treated with protective coatings. Galvanisation, where the steel is coated with a layer of zinc, can offer some protection. Additionally, high-quality paints or powder coatings can also be applied. However, these coatings can wear or chip over time, especially in areas of high friction or impact, so periodic re-application or touch-ups may be necessary.

Alternative Materials: Given the challenges posed by marine environments, many projects in these areas opt for more corrosion-resistant materials like stainless steel or aluminum. While these materials come at a higher initial cost, they can offer longer lifespans and reduced maintenance needs.

Modern perforating techniques allow for a high degree of customisation, and you can have a logo, specific design, or intricate pattern perforated into a mild steel sheet. Advanced machinery, such as CNC-controlled punching machines and laser cutting equipment, enable precise and detailed perforations that can accurately represent logos or specific designs. When opting for such customisation, it’s crucial to work closely with the manufacturer or fabricator to ensure the design’s feasibility and maintain structural integrity. High-definition designs might require fine-tuning to ensure that the perforated sheet remains strong and the design remains recognisable. Moreover, considerations such as the sheet’s thickness, hole size, pitch, and the overall size of the design play a role in the final outcome. But with the right expertise and equipment, creating custom perforations for branding, aesthetic, or functional purposes in a mild steel sheet is very achievable.

Mild steel perforated mesh has limited resistance to chemicals, especially when compared to certain other materials like stainless steel or specialised plastics. Here’s a closer look at its performance when exposed to chemicals:

Corrosion: Mild steel, by its nature, is susceptible to oxidation and corrosion when exposed to many chemicals, especially strong acids and alkalis. The perforations in the mesh can increase the surface area exposed, potentially accelerating the rate of corrosion.

Protective Coatings: To improve its chemical resistance, mild steel perforated mesh can be treated with protective coatings or paints. These coatings can act as a barrier, reducing direct exposure to the chemical agents. However, the effectiveness of these coatings can vary depending on the specific chemicals involved and their concentration.

Environmental Factors: The presence of moisture, oxygen, and certain salts can also influence how mild steel reacts with chemicals. For instance, in humid conditions or when there’s salt in the environment, the corrosion process can be more aggressive.

Specific Chemicals: While mild steel might handle some dilute chemicals or organic solvents reasonably well, it can corrode rapidly when exposed to strong acids like hydrochloric or sulfuric acid. Furthermore, some chemicals can act as catalysts, accelerating the rusting process.

Alternatives for Chemical Resistance: For environments or applications where there’s a consistent exposure to aggressive chemicals, alternatives like stainless steel or even specific plastics might be more appropriate. Stainless steel, especially certain grades, offers excellent resistance to a broad range of chemicals.

Check out our blog discussing What is Perforated Mesh. It will prove a useful read to help you to make an informed decision on which material would work best for you.

We are also very proud of our ever expanding YouTube channel.

Our goal for our blogs, videos and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact us today if you have any questions at all. We are always really keen to help in any way that we can.

We are also very proud of our highly popular eBay store, check us out there too.

Thank you for checking out our product.

£24.99 – £46.99Price range: £24.99 through £46.99 inc VAT

£24.99 – £54.99Price range: £24.99 through £54.99 inc VAT

£24.99 – £46.99Price range: £24.99 through £46.99 inc VAT

£24.99 – £54.99Price range: £24.99 through £54.99 inc VAT