- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

£11.99 – £24.99Price range: £11.99 through £24.99 inc VAT

This website is secured:

£ MULTIBUY SAVINGS – Order 3 For 10% Off

✔ Specialists In Rapid Shipments Of Any Size

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

£ Check Out Our Clearance Listing For Savings

@ ☏ Bespoke Cuts & Larger Lengths Available

If you’re looking for a versatile and durable metal thin sheet plate, look no further than the 0.9mm thick mild steel plate by Speciality Metals. You can trust the top quality of this UK-manufactured product, whether you need it for a DIY project at home, for work in your metal workshop or for any industrial application. With great weldability, machinability, formability and bendability, this sheet plate can be easily molded into virtually any desired shape. It comes in various sizes, so you’ll always find the perfect fit for your project, no matter the scope.

Whatever you need it for, this metal thin sheet plate is sure to meet and exceed your expectations.

Mild sheet steel metal plate is the most popular product that we offer. It is a quality strong metal for myriad DIY and industrial applications. The uses for mild steel plate metal include automotive bodywork, boxes and security doors.

Speciality Metals offers a top-quality 0.9mm thick mild steel metal thin sheet plate that is versatile, durable and offers great weldability, machinability, formability and bendability. This metal thin sheet plate is available in various sizes to support a full range of applications, making it an ideal choice for those looking for a reliable and high-quality construction material. Not only is this metal thin sheet plate the perfect choice for projects with specific size requirements, but it is also a preferred option for any project that requires a reliable and versatile construction material. By choosing Speciality Metals for your metal thin sheet needs, you can rest assured that you are choosing a company that is committed to providing customers with top-quality products and excellent service.

We also offer mild steel off-cuts too if that suits your requirement better.

Sheet metal is also available in aluminium and stainless steel.

Speciality Metals is known to be the United Kingdom’s best up-and-coming small-quantity metal company.

Furthermore we stock a vast range of plain sheet plate options that compliment our mesh range perfectly.

Over 50,000 customers of Specialty Metals are provided with fast, friendly customer service every year. We’re the place to try when you need metal of any shape and size. We’re based in Warrington, UK. We pride ourselves on our rapid turnaround and a large range of options.

Mild steel, such as that found in a 0.9mm thick sheet, is not naturally weather-resistant. When exposed to moisture or high humidity, mild steel can oxidise, which results in rust formation. This means that if the 0.9mm thick mild steel sheet is used in an outdoor environment or other areas where it’s exposed to the elements, it’s likely to rust over time. However, there are ways to enhance the weather resistance of mild steel. One common method is galvanisation, which involves coating the steel with a protective layer of zinc. The zinc acts as a barrier against moisture, preventing the underlying steel from rusting. Another method is applying a coat of paint or a similar protective layer, which also acts as a barrier against moisture.

There are also other treatments and coatings that can increase the corrosion resistance of mild steel, such as powder coating, thermal spraying and applying rust-resistant primers or sealants. These treatments can help to prolong the lifespan of mild steel when used in weather-exposed conditions. However, even with these treatments, mild steel may not be as weather-resistant as other types of steel, such as stainless steel or weathering steel, which are designed to resist corrosion more effectively. Therefore, while a 0.9mm thick mild steel sheet can be made more weather-resistant, it might not be the best choice for applications where high weather resistance is required.

As always, it’s recommended to consult with a professional or the manufacturer to determine the best material for your specific application and environment.

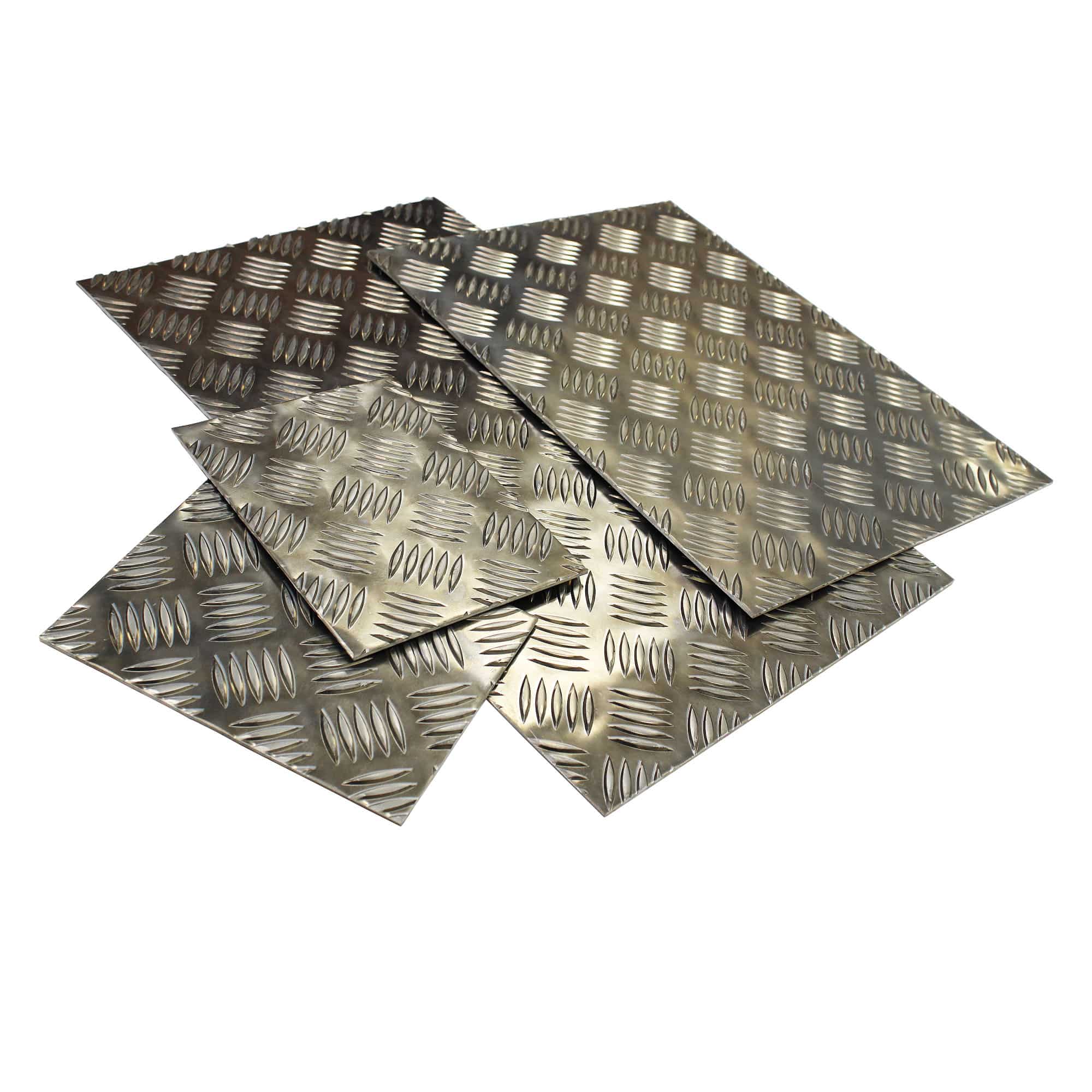

A 3mm thick mild steel sheet can indeed be used as flooring, but the suitability largely depends on the specific application. In some industrial and commercial settings, steel flooring is common because of its high strength and durability. For example, it can be used in warehouse floors, loading docks and other areas that need to withstand heavy loads or high traffic. However, mild steel is prone to corrosion, particularly when exposed to moisture or chemicals. Therefore, if it’s used as flooring in an environment where it could get wet or be exposed to corrosive substances, it would need to be treated or coated to prevent rusting. Common treatments include painting, galvanising (coating with zinc), or applying a powder coat, which not only increase the corrosion resistance but also can provide a more attractive finish.

The use of mild steel for flooring also has other considerations. For instance, steel is a hard and unforgiving material, so it may not be the best choice for areas where people will be standing for long periods of time. It can also be slippery when wet, although this can be mitigated by using steel with a patterned or textured surface to increase traction.

Lastly, while a 3mm thickness can provide a substantial amount of strength, the exact loading capacity would depend on other factors such as the size of the sheet and the support structure underneath. For heavy-duty applications, a thicker sheet or additional supports might be necessary.

When handling 0.9mm thick mild steel metal thin sheet plates, safety should always be the primary concern. To ensure safe handling, appropriate protective gear should be worn at all times. This includes heavy-duty gloves to safeguard your hands from the steel’s sharp edges or corners and safety glasses to protect your eyes from any small particles that might get dislodged. Correct lifting techniques are crucial to avoid any strain or injury, and if the steel sheet’s size and weight make manual handling difficult, the use of additional tools or lifting equipment like forklifts may be necessary. It’s also essential to ensure the immediate surroundings are clear of obstacles to avoid accidents when moving the sheets. Once placed, the steel sheets should be securely positioned to prevent them from sliding or falling. Proper storage of these sheets is equally important; they should be stored in a safe, flat area where they aren’t prone to causing accidents or getting damaged. Always remember, if there’s ever any uncertainty about safely handling these materials, seeking advice from a professional or an experienced individual is the best course of action.

Bonding a 0.9mm thick mild steel metal thin sheet plate to another surface can be accomplished through a few different methods, depending on the other material and the specific requirements of the project. One common method is welding. Mild steel is known for its excellent weldability, and can be joined to other pieces of steel or different metals through various welding techniques, such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding. However, the thinness of a 0.9mm sheet can make welding more challenging and may require a skilled welder or precise welding techniques.

Another approach is using mechanical fasteners like screws, bolts or rivets. This can be an effective way to bond steel to other materials, including non-metals and has the advantage of being reversible if needed. However, it does require the ability to drill or punch holes in the materials without causing damage. Adhesives can also be used to bond mild steel to various surfaces. There are industrial adhesives available that can create a strong bond between metal and other materials. It’s important to choose an adhesive that is suitable for the specific materials and conditions (such as temperature and moisture levels) and to follow the manufacturer’s instructions for preparation and application.

Lastly, for bonding to certain materials or for large-scale applications, more specialized techniques might be needed. These could include soldering, brazing or thermal spraying. Regardless of the method used, it’s essential to properly clean and prepare the surfaces to be bonded, as dirt, grease or rust can interfere with the bonding process. Always remember to take appropriate safety precautions when working with these materials and tools.

Check out our recent article ‘Cold Rolled vs Hot Rolled Steel’ for a deeper dive into mild steel metal. We have also recently written an article explaining how to cut metal, which is well worth a read before you select the metal that best suits your requirement.

We are also adding product videos to our YouTube channel. Our goal for our blogs, videos and help guides is to answer as many questions as possible to help to explain the possibilities of metal materials to our customers.

Contact us today if you have any questions at all. We are always really keen to help in any way that we can.

We are also very proud of our highly popular eBay store, check us out there too.

£13.99 – £30.49Price range: £13.99 through £30.49 inc VAT

£17.99 – £54.99Price range: £17.99 through £54.99 inc VAT

£13.99 – £30.49Price range: £13.99 through £30.49 inc VAT

£17.99 – £54.99Price range: £17.99 through £54.99 inc VAT