- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

£2.91 – £19.58 inc VAT

Secure payments taken with:

This website is secured:

£ MULTIBUY SAVINGS – Order 3 For 10% Off

✔ Specialists In Rapid Shipments Of Any Size

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

@ ☏ Bespoke Cuts & Larger Sheets Available

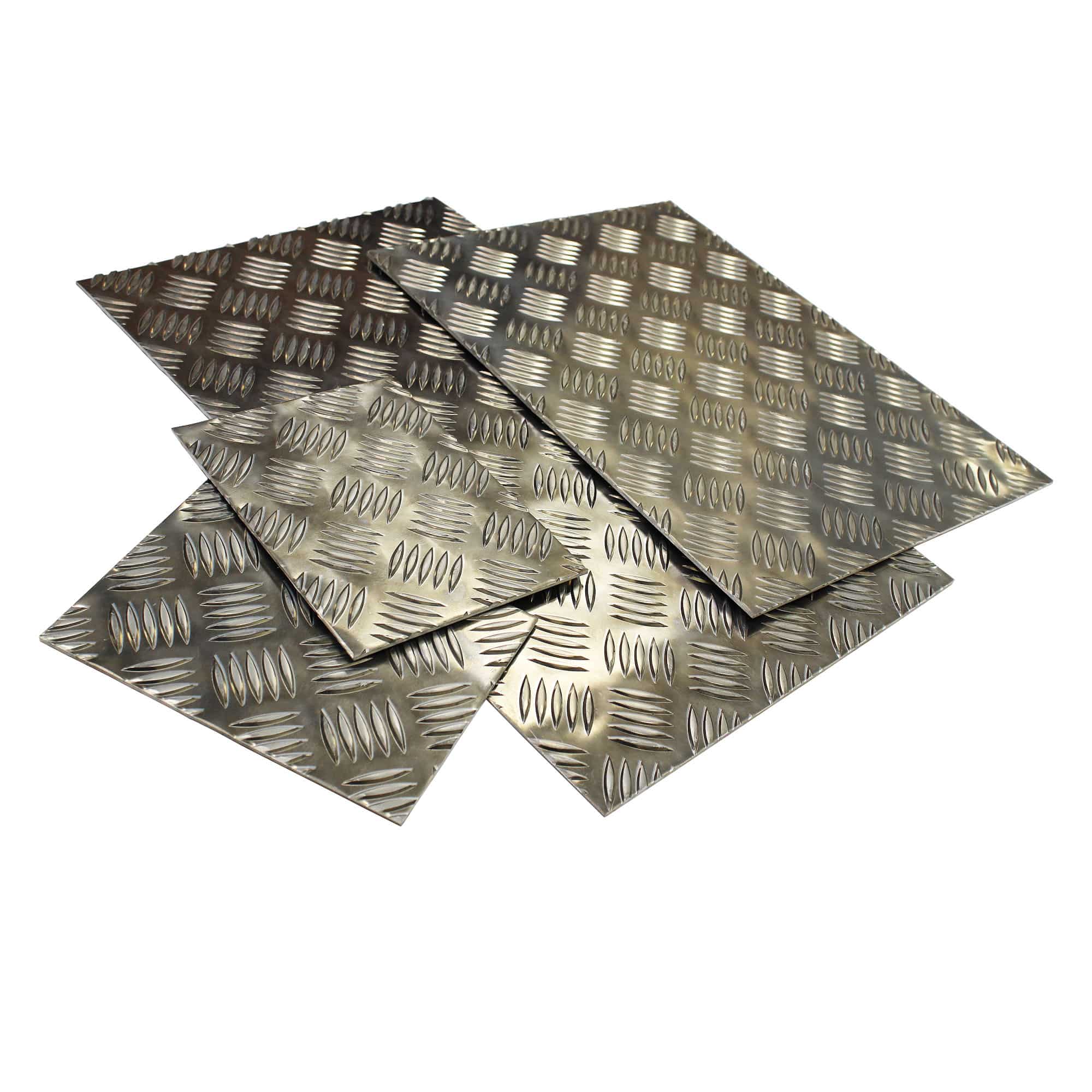

At Speciality Metals, we take pride in offering top-quality galvanised steel sheet metal plates that are built to last. Our 0.9mm thick sheets are expertly coated with zinc, making them highly resistant to corrosion and ensuring longevity. We supply various sizes that can be used for a range of applications, making them incredibly versatile. Whether you’re looking for a reliable material for roofing, fencing or even industrial machinery, our galvanised steel sheets are sure to meet your needs. So, if you’re searching for durable and dependable metal plates, look no further than Speciality Metals.

We offer a wide selection of galvanised sheet metal online from trusted mills within the UK. Providing high-quality, low-priced galvanised sheet products to UK businesses and the general public, Speciality Metals is a leading galvanised metal supplier.

When it comes to sturdy and long-lasting metal plates, nothing beats galvanised steel sheet. With a thickness of 0.9mm and a zinc coating for superior corrosion resistance, Speciality Metals’ galvanised steel sheet offers top-quality performance that can withstand even the toughest conditions. Whether you need it for construction, manufacturing or DIY projects, our galvanised steel sheet is a versatile material that comes in various sizes to fit your specific needs. Plus, with our UK supply, you can trust that you are getting a fast and reliable service.

We are the best suppliers for your needs because:

Quick product details:

Sheet metal is also available in aluminium and stainless steel.

Yes, galvanised steel plates can be welded, but special considerations and precautions are necessary due to the presence of the zinc coating. During the welding process, zinc fumes may be released, which can be harmful if inhaled. Therefore, it is crucial to take appropriate safety measures, such as ensuring proper ventilation in the welding area and wearing suitable respiratory protection.

Before welding, the zinc coating must be carefully removed from the areas that will be welded to ensure a sound and strong weld. Welding over the zinc coating can result in poor adhesion and weak welds, compromising the overall integrity of the joint. Common methods to remove the zinc coating include mechanical cleaning, grinding or chemical cleaning. Once the zinc is removed, the welding process can proceed using standard welding techniques, such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding or arc welding.

After welding, it is essential to inspect the welded area for any signs of zinc reformation or spatter and promptly remove any remaining zinc deposits to avoid potential corrosion issues. While galvanised steel can be welded successfully, it’s advisable to consult with experienced welders or follow the manufacturer’s recommendations and safety guidelines to achieve proper and safe welds. By adhering to these precautions, galvanised steel plates can be effectively welded for various fabrication and construction applications.

0.9mm thick galvanised steel sheet metal plates find numerous applications across various industries due to their excellent corrosion resistance and durability. Some common applications for these plates include roofing and siding for residential and commercial buildings, where the galvanised coating protects against weathering and extends the lifespan of the materials. They are also used in HVAC (heating, ventilation, and air conditioning) systems for ducting and components that require resistance to moisture and external elements. In the automotive industry, galvanised steel plates are used for automotive body parts and undercarriages to enhance their resistance to road salts and environmental exposure. Additionally, these plates are employed in electrical enclosures and cable trays, as the zinc coating provides protection against indoor humidity and corrosion. Moreover, 0.9mm thick galvanised steel plates are utilized in general fabrication projects, such as metal containers, agricultural equipment, and various structural components, where durability and corrosion resistance are essential for extended service life.

Yes, 0.9mm thick galvanised steel plates can be painted or coated, but proper surface preparation is crucial to ensure the adhesion and longevity of the paint or coating. The zinc coating on galvanised steel provides an excellent surface for paint adhesion, but it must be cleaned and primed correctly to achieve the best results.

Before painting, the surface of the galvanised steel plate should be thoroughly cleaned to remove any dirt, oil or contaminants. This can be done using a mild detergent or a solvent suitable for cleaning metal surfaces. After cleaning, the surface should be rinsed and allowed to dry completely before applying any paint or coating.

To improve the adhesion of the paint or coating, a suitable primer designed for use on galvanised surfaces should be applied. The primer creates a bonding layer between the galvanised surface and the paint, ensuring better adhesion and preventing premature peeling or chipping.

When choosing paint or coating for galvanised steel plates, it is essential to select products that are compatible with metal surfaces and offer good adhesion and weather resistance. Additionally, the paint or coating should be suitable for the intended application, whether it’s for outdoor use, high-temperature environments or specific industrial requirements.

By following these steps and using the right paint and primer, galvanised steel plates can be effectively painted or coated to meet aesthetic, protective or functional needs, while preserving the underlying corrosion resistance provided by the galvanised coating.

Proper storage and handling of galvanised steel plates are essential to maintain their quality and prevent damage to the zinc coating. When storing these plates, it is crucial to keep them in a dry, covered area to protect them from exposure to moisture and humidity. If the plates become wet, ensure they are dried thoroughly before stacking or storing them to avoid potential corrosion.

When handling galvanised steel plates, it’s essential to exercise care to prevent scratching or damaging the zinc coating. Avoid dragging the plates on rough surfaces or against each other, as this can cause abrasions that may compromise the corrosion resistance of the coating. Using appropriate lifting equipment or protective materials between plates can help prevent surface damage during transportation and storage.

Additionally, avoid storing galvanised steel plates in direct contact with non-compatible materials, such as copper or untreated steel, as this can lead to galvanic corrosion. Separating different metals and using non-reactive materials in storage areas can prevent such issues.

Labeling the galvanised steel plates with their dimensions or other relevant information can facilitate easy identification and handling. Regular inspections of the stored plates are advisable to detect any signs of damage or corrosion early on, enabling prompt actions to address any issues.

By following these storage and handling practices, galvanised steel plates can be kept in optimal condition, ensuring their long-term durability and corrosion resistance when used in various construction, fabrication and industrial applications.

Check out our recent article ‘Galvanised Steel vs. Aluminium – The Pros and Cons‘ for a deeper dive into all things galvanised sheet metal.

We are also very proud of our ever expanding YouTube channel.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact us today if you have any questions at all. We are always really keen to help in any way that we can.

We are also very proud of our highly popular eBay store, check us out there too.

Thank you for checking out our product.

£11.66 – £25.41 inc VAT

£13.33 – £51.66 inc VAT

£11.66 – £25.41 inc VAT

£13.33 – £51.66 inc VAT

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options