- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Mastering Precision Cuts: The Sheet Metal Nibbler Guide

During the meticulous process of sheet metal fabrication, the quality of cutting determines not only the outcome but also the efficiency of assembly and the integrity of the finished product. The importance of clean cutting cannot be overstated; it ensures precise dimensions, protects material integrity, and prepares edges for seamless joining or welding.

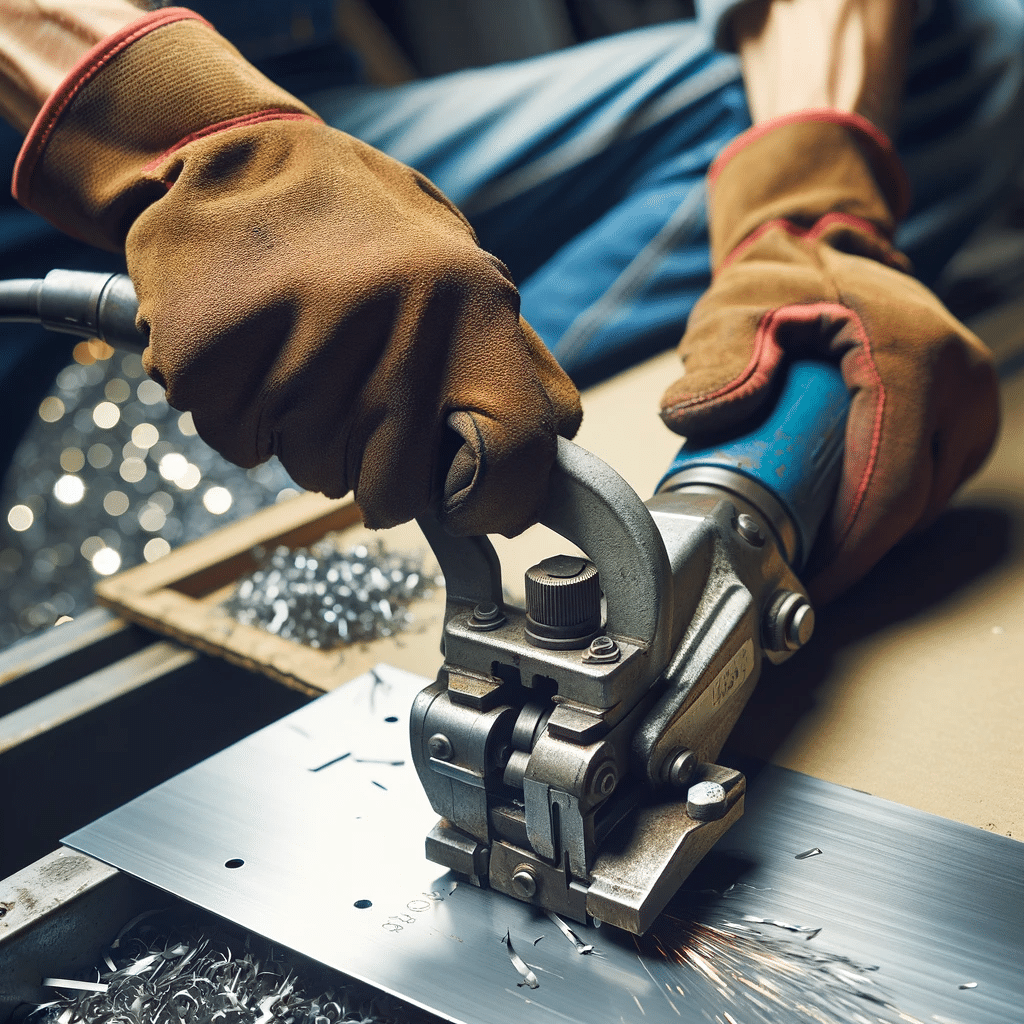

Sheet metal nibblers are revered for their ability to make clean, precise cuts without warping or bending the workpiece. By using a punch-and-die mechanism, nibblers can make incisions that are both accurate and aesthetically pleasing, unlike saws that can cause rough edges.

We offer a wide range of sheet metals, each with its own characteristics and cutting requirements. The versatility of the sheet metal nibbler makes it a preferred choice for working with our extensive range, from the delicate precision needed for thin copper sheets to the robust force required for thicker stainless steel. This guide introduces you to the indispensable nibbler, illuminating how it stands as an essential instrument within the Speciality Metals toolkit, ready to tackle a project of any calibre with finesse.

Let’s get into it…

Sheet metal nibblers are used for cutting sheet metal with precision and minimal distortion. With this tool, small pieces of metal are rapidly punched out of the sheet, creating a clean, burr-free cut line. A punch and die work together to nibble through metal as the tool advances, producing this cutting action.

There are many advantages to using a nibbler. Nibblers are capable of making cuts in any shape, including straight lines and curves, without compromising the material’s integrity. They can navigate tight patterns and complex designs that other cutting tools would struggle with. Additionally, nibblers produce no sparks and leave behind minimal waste, reducing the risk of injury from sharp edges.

Nibblers come in various forms to suit different project needs. For small or occasional jobs, manual nibblers offer simplicity and control. In larger projects, electric nibblers are ideal for prolonged use because they provide more power. The pneumatic nibbler, which requires an air compressor, is lightweight and can cut through thicker metals.

In order to achieve a cut, the mechanics of a nibbler involve orchestrating several components. The heart of the nibbler is the punch-and-die mechanism. The punch moves up and down, driven either manually or by an electric or pneumatic motor, pushing the metal into the die which has a matching shape. During the cutting process, the punch removes small chunks or ‘nibbles’ of metal from the metal.

Various nibbler models are designed to handle different thicknesses and types of sheet metal, based on their technical specifications. Often, electric and pneumatic nibblers have adjustable speeds and are capable of cutting metals from thin aluminium foils to steel sheets several millimeters thick.

Keeping a nibbler in good working order involves regular checks and replacements of the punch and die. Maintenance, lubricating moving parts, and keeping the tool clean from metal shavings ensure its longevity and performance. When cared for properly, a nibbler can be a reliable addition to a metalworker’s arsenal.

Choosing the correct nibbler is pivotal to achieving the best results in sheet metal work. The decision hinges on the type of metal you’re working with and its thickness. Here’s a guide to help you select the ideal nibbler for your project from the range offered by Speciality Metals:

Mild Steel: The right nibbler is essential when working with mild steel, a robust and durable material commonly used in construction and automotive industries. The carbon content in mild steel makes it stronger and harder than aluminium, requiring a stronger nibbler, such as an electric or pneumatic model. Especially for structural components, these nibblers can handle the rigidity and thickness of mild steel. Maintaining the punch and die sharp is crucial to ensuring clean cuts without burrs. Due to mild steel’s tendency to rust, both the metal sheets and the nibbler tool must be handled with care.

Aluminium 5 Bar Checker Plate: Aluminum 5 bar checker plate requires a nibbler that can navigate its unique texture to be cut due to its distinctive raised pattern and non-slip properties. In order to maintain the integrity of the raised pattern while cutting, an electric nibbler is often the tool of choice. Manipulation of the tool should be carefully controlled to avoid flattening or distorting the pattern. For both safety and visual appeal, checker plates are used for decorative and functional applications such as flooring and wall cladding. The nibbler should be cleaned regularly to prevent build-up from aluminium’s softer material, which can clog it.

Stainless Steel: It is often preferable to use a pneumatic nibbler for stainless steel grades 304 and 316. Because of its power and speed, it can handle the strength of metal.

Copper: The manual nibbler is capable of handling thin copper sheets, but electric nibblers offer the finesse required for this ductile metal without distorting its shape.

In comparing nibbler models, consider the maximum cutting capacity, which indicates the thickest metal it can cut. Make sure the nibbler can make the cuts you need by assessing the minimum cutting radius.

Cutting sheet metal with a nibbler requires precision and care. Here’s a step-by-step approach for using a nibbler:

When cutting different metals, keep in mind that softer metals, such as aluminum, may require a slower cutting speed to prevent tearing. Harder metals, such as stainless steel, may require multiple passes. Wear appropriate safety gear, including gloves and eye protection, and work in a well-lit, stable environment.

The versatility of nibblers makes them an invaluable tool for a wide array of projects. Here are a few examples:

Maintaining your sheet metal nibbler properly will ensure its longevity and optimal performance. Below are some troubleshooting tips and routine maintenance tips:

Lubrication: Lubricate the nibbler’s moving parts regularly to reduce friction and prevent wear. Lubricate the machine with a light machine oil.

Cleanliness: Remove any metal shavings or debris from the nibbler after each use. By doing so, particles that could hinder its operation are prevented from accumulating.

Inspect Punch and Die: Make sure the punch and die are regularly checked for wear and damage. Poor cutting performance can be caused by dull or damaged punches or dies. If they show signs of significant wear, replace them.

Check for Loose Parts: Make sure all screws and bolts are tight. It is possible for loose parts to affect the accuracy of the nibbler and possibly damage it.

Storage: Store the nibbler in a dry, clean environment to prevent rust and corrosion.

Common Issues and Troubleshooting:

When to Replace vs. Repair:

Known for its precision, versatility, and ability to produce clean cuts in various metals, the sheet metal nibbler stands out as an indispensable tool in metal fabrication. Intricate cuts can be handled easily with this tool, making it an essential tool for professionals and hobbyists alike. Maintaining your nibbler properly ensures its longevity and reliability, and selecting the right nibbler for your particular metal type and thickness is crucial.

Speciality Metals understands the importance of having the right tools. Explore our range of high-quality sheet metals, ideal for use with nibblers, to bring precision and excellence to your projects. Our selection covers all your sheet metal needs, whether you are cutting aluminium, stainless steel, or copper. Connect with us today to find the ideal materials for your next project and to get expert advice on the best tools for your requirements.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options