- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Mastering Metal Grades: A Deeper Dive into Stainless Steel and Aluminium Varieties

In the metallurgical universe, understanding the distinctive grades of metals, especially Stainless Steel and Aluminium, is imperative for ensuring the success of a project.

At Speciality Metals, we pride ourselves on offering an array of grades, tailored to cater to various applications. Let’s embark on a detailed exploration of these grades, highlighting their unique properties and potential uses.

Let’s get into it…..

A stainless steel alloy is an amalgamation of steel alloys that contain a minimum of 10.5% chromium content and is often regarded as the marvel metal.

By adding chromium to steel, it produces a thin layer of oxide on its surface, giving it its corrosion-resistant properties. This broad umbrella term of stainless steel encompasses a vast landscape of varieties, each with its own characteristics, advantages, and applications.

Molecular Architecture: The fundamental structure of stainless steel can be classified into several families, based on its crystalline structure:

Austenitic: Known for its formability and weldability, this material is non-magnetic and non-magnetic. Stainless steels such as 304 and 316 grades are resistant to corrosion because of their face-centred cubic crystal structure, which is referred to as austenite. Alloys within the austenite family, such as the 304 grade, are particularly corrosive-resistant.

Ferritic: Magnetic stainless steel with a body-centred cubic crystal structure, known as “ferrite.” Grade 430 belongs to this category. Despite the fact that it does not have the same level of corrosion resistance as its austenitic counterparts, this alloy has excellent engineering properties.

Martensitic: It is important to note that these steels are somewhat similar to ferritic steels, though they can be hardened through heat treatment. This type of steel is magnetic, and it is often used in products that are required to be both strong and corrosion-resistant.

Why Stainless Steel?: Stainless steel’s soaring popularity isn’t solely attributed to its resistance to rust. Other intrinsic benefits include:

Temperature Resistance: Certain grades can resist scaling and maintain integrity in temperatures up to 1100°F or higher.

Strength-to-weight Advantage: Aerospace and automotive industries often turn to high-strength stainless steel for its strength-to-weight ratio, which is often superior to other materials.

Aesthetics: Its ability to maintain a shiny, sleek finish makes it a darling of architects and designers. From skyscrapers to intricate sculptures, stainless steel’s allure lies in its gleaming aesthetics coupled with functionality.

Hygienic Properties: Its non-porous surface makes it an ideal choice for medical facilities, food production, and kitchens.

Stainless Steel 304 (1.4301): The corrosion resistance and versatility of 304 remain unparalleled in the austenitic stainless steel family. This grade’s popularity stems from its multifaceted properties:

Typical Applications:

Stainless Steel 430 (1.4016): The high chromium stainless steel grade has admirable corrosion resistance, formability, and premium finish due to its non-hardenable nature.

Typical Applications:

Standards and Specifications: Speciality Metals ensures adherence to EN 10088-2:2005 for stainless steel, but also offers products compliant with ASTM and other international standards, providing consistent quality across the board.

The most abundant metal on Earth, aluminium is lightweight, malleable, and corrosion-resistant. Due to its unique properties, it is a sought-after material for a wide variety of uses.

Aluminium’s Distinctive Properties:

Lightweight: In applications where weight savings are important, aluminium is an ideal choice since it weighs approximately one-third as much as steel or copper.

Thermal Conductivity: The thermal conductivity rate of aluminium exceeds that of steel, making it ideal for heat transfer applications such as air conditioning units and automobile radiators.

Corrosion Resistance: When exposed to air, aluminium forms a transparent oxide layer that provides protection against corrosion.

Electrical Conductivity: On a weight-to-weight basis, aluminium can conduct twice as much electricity as copper, positioning it as a vital material in power transmission lines.

Applications Abound: Given its multifaceted attributes, aluminium finds itself at the heart of numerous applications:

Transport: The automotive and aerospace sectors leverage aluminium’s lightweight nature to manufacture fuel-efficient vehicles and aircraft.

Packaging: Aluminium’s non-toxic nature and resistance to corrosion make it a top choice for beverage cans and food packaging.

Construction: Given its resistance to corrosion, aluminium is used extensively in window frames, roof coverings, and facades.

Electronics: The electrical conductivity of aluminium makes it an essential component in electronics, including smartphones, televisions, and more.

Furthermore, aluminium’s recyclability is another feather in its cap. Without any compromise on quality, aluminium can be recycled multiple times, aligning with global efforts towards sustainability and reduced carbon footprints.

Grade 1050A H14 Aluminium Sheets: An embodiment of purity in the realm of aluminium, the 1050A H14 grade is appreciated for its strength and high recyclability.

Typical Applications:

6000 Series Aluminium Long Products (6082T6 or 6063T6): Positioned as a medium-strength alloy, the 6000 series stands out for its corrosion resistance, making it a staple for various structural elements.

Typical Applications:

Grade Insights: The 6000 series is one of the most preferred choices in the aluminium category due to its adaptability and heat treatability.

It can be difficult to navigate the world of metal grades, but with the right knowledge and guidance, you can maximise each grade’s potential. Our mission at Speciality Metals is to empower our clients with superior quality metals and insights to ensure their projects stand out both in durability and aesthetics.

Stainless Steel Grades:

Aluminium Grades:

Key Takeaway:

The proper understanding and selection of metal grades can have a significant impact on the quality and longevity of a project, as well as the cost.

Poor selection of metal grades can lead to corrosion, reduced durability, and higher costs for repair or replacement. It is therefore essential to consider all of the relevant factors when selecting a metal grade for any project.

As always, thank you for checking out our blog. We hope that this helps you with your project.

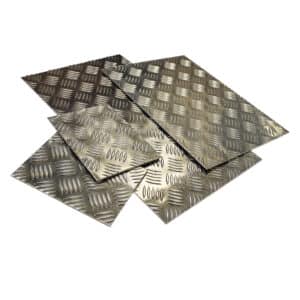

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options