- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Is Stainless Steel Magnetic?

Stainless steel is one of those metal alloys where people are unsure if it’s actually magnetic or not. To tell the truth, there are some grades of stainless steel that are magnetic however is most cases it’s not a magnetic alloy and isn’t often used to attract magnetic forces.

A grade of stainless steel we supply is 430 grade, this is one of the grades that is magnetic. We hope our expert information will help you understand the different of magnetic and non-magnetic stainless steel and how they are both used.

Stainless steel is a metal alloy found in iron. It’s contains a combination of elements such as chromium and carbon, it has incredible strength and is resistant to corrosion. Because of it’s high strength, it’s a more superior metal compared to copper and aluminium for a few reasons.

Firstly, stainless steel has the highest melting point of about 1,500 degrees Celsius. This is the highest as the melting point of aluminium is about 660 degrees Celsius and copper is 1,085 degrees Celsius. This makes stainless steel the best conductor of heat.

Magnetic stainless steel also is the most resistant to corrosion. The element chromium in stainless steel and the added nitrogen increases the resistance of corrosion and mechanical strength. This means the metal is long lasting and won’t deteriorate it damn or extreme weather conditions.

Some stainless steel grade are actually magnetic. Usually stainless steel is not a magnetic alloy however 430 grade (a grade that we supply) is a ferritic alloy of stainless steel and is used widely for commercial and domestic applications such as hinges, refrigerator panels, automotive trims, fasteners and more.

For stainless steel to be magnetic, it should contain iron, a high level of ferrite (which is a combination of iron and other elements) and have a crystal structure.

430 grade contains mostly iron, chromium with molybdenum content. This combination of elements allow 430 grade to have improved resistance to corrosion. It’s also often used in chemical appliances due to its resistance to nitric acid.

Advantages

Some non-magnetic grades of stainless steel that we supply are 340 and 316 grade. These are austenitic stainless steel grades.

Non-magnetic grades such as 340 and 316 contain a high amount of molybdenum combined with iron, chromium and nickel. This compound allows for these grades to have great formability and weldability.

304 is the most common grade used in general, it’s often used in construction and household applications such as: piping, fasteners, refrigerators and dishwashers.

316 is a marine grade stainless steel therefore it’s ideal for applications involving water. It has higher strength and resistance to chemicals however is it more expensive than 304.

Advantages

The main difference between ferritic steel and austenitic steel is that ferritic steels are magnetic and austenitic steel is non-magnetic.

Ferritic steel contains a form of iron structured in a crystal form mixed with a small amount of carbon. Thus gives the steel its magnetic properties. The downside to ferritic steel is that it is less resistant to corrosion than austenitic steel and is not as strong.

Austenitic steel is non-magnetic and consists of austenite which is a stronger form of iron. It can absorb more carbon and has a higher resistance to corrosion. It’s structured in a cubic crystal structure which gives it a higher melting point.

Grade 304 stainless steel is the most common form of stainless steel used globally. Because of its high strength, versatility and resistance to corrosion, it’s the perfect material for construction and house hold appliances. It’s an austenitic steel made from compounds of nickel, iron and chromium.

This grade it the most durable and long lasting grade of stainless steel. Therefore there are countless ways in which you can use it. It also has a high resistance to heat and oxidation, you’ll often find it used as pipes, tools, cutlery, science and surgical equipment, food processing, aircraft and more.

Grade 316 is also an austenitic steel and a marine grade of stainless steel. This makes it perfect for situations that involve water or chemicals. This is because 316 grade doesn’t corrode when these elements are used constantly due to its molybdenum content. However, it must be known that even though it is marine grade, it is not actually resistant to sea water. It is only resistant to clean water and chlorine water and environments. This grade has great forming and welding abilities and has a relatively high heat resistance.

On the contrary, 430 grade is a ferritic steel. It has good resistance to corrosion, it’s also got magnetic properties and has great welding abilities and machinability. 430 grade stainless steel is commonly used in domestic appliances such as dishwasher linings, utensils, food and wall cladding, heat-resisting applications and automotive trims due to it’s resistance to heat and chemicals.

However, because of the crystal atom structure, it’s not as durable as grades 304 and 316 which have cubic structures.

Advantages of stainless steel (compared to other metals)

Disadvantages of stainless steel (compared to other metals)

Magnetic stainless steel and non-magnetic stainless steel are both versatile materials. Here are some ways in which they are used:

Magnetic:

Non-magnetic:

While stainless steel is generally non-magnetic, it’s essential to recognise that variations in alloy composition can result in magnetic properties.

By understanding these nuances, we can make informed decisions when selecting stainless steel sheet metal for various applications, ensuring optimal performance and meeting specific requirements.

As always, thank you for checking out our blog. We hope that this helps you with your project.

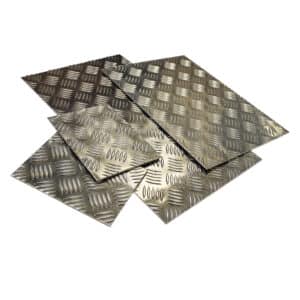

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options