- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » How to Cut Metal – A Beginner’s Guide

Cutting metal is likely to be a task that you may need to undertake at some point in your life, whether it’s for a DIY project, home improvement, or even for a professional job.

Cutting metal can be intimidating for beginners, especially if you’ve never worked with metal before.

However, with the right tools and techniques, cutting metal can be a breeze. In this blog post, we’ll discuss the different methods on how to cut metal, the tools you’ll need, and some helpful tips and tricks for beginners.

Let’s go…

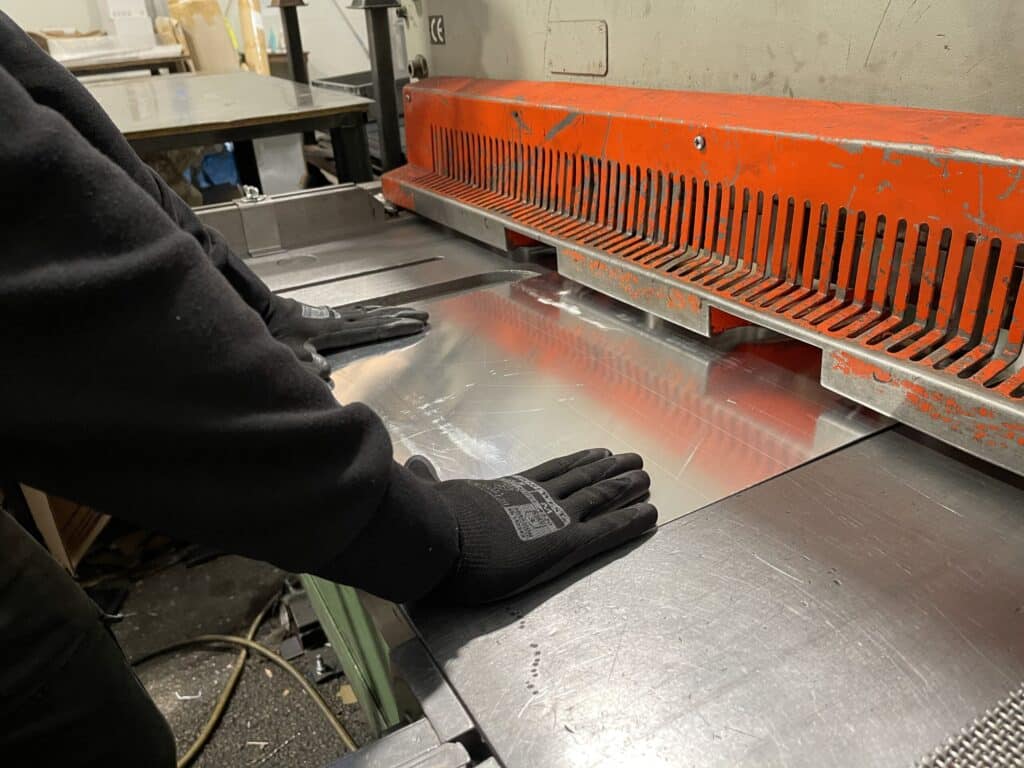

We have two large industrial guillotines, which we use for cutting our sheet metal and perforated mesh materials.

For our tube, angle and box section we use a chop saw.

Of course, most do not have access to this type of equipment. This article will focus on alternative means of cutting, which are available to the majority of our customers.

One of the most popular ways of cutting metal is by using a metal cutting saw. This is because it is fast, efficient and produces clean and precise cuts.

A metal cutting saw is a power tool that uses a circular blade to cut through metal. The saw blade can be made of different materials such as tungsten carbide, diamond or high-speed steel depending on the type of metal you are cutting.

To use a metal cutting saw, secure the metal workpiece tightly in a metal vice or clamp, then align the saw blade with the cutting line, switch on the saw and push the saw through the metal. It is simple, but care will still need to be taken at all times. Remember always to wear protective gear, such as a mask and safety glasses.

Another method of cutting metal is with a plasma cutter.

A plasma cutter uses an electrical arc and compressed air to cut through metal. This method is particularly useful for cutting thicker metals, and it provides a smoother edge than other methods. To use a plasma cutter, you will need to connect the cutter to a power source, attach the correct nozzle size, adjust the amperage settings to suit the type of metal and thickness you want to cut, then hold the cutter at a 90-degree angle to the metal and move it along the cutting path.

A jigsaw is a handheld power tool that uses a reciprocating blade to cut through metal.

It’s an affordable alternative to a metal saw, and it’s versatile enough to cut curves and rounded shapes. To use a jigsaw for cutting metal, choose a blade appropriate for metal cutting and clamp the metal to a workbench securely.

Before you begin you must mark the cutting line, then turn on the jigsaw and gradually guide it along the line to make the cut.

A hacksaw is a handheld tool that uses a U-shaped blade to cut through metal.

They are affordable, portable, and require no power source. To cut metal using a hacksaw, you will need to clamp the metal to a secure workbench, then mark the cutting line with a marker. After that, install a hacksaw blade that is appropriate for the metal, and cut through the metal using back and forth strokes with moderate pressure. Changing the blades regularly can prevent the hacksaw blades from wearing out or snapping.

Before cutting metal, it’s always a good idea to prepare yourself and your workspace.

Always wear protective gloves, a mask, and safety glasses to protect yourself from metal chips and bits.

Be sure to prepare your metal workpiece by removing any debris, burrs, or coatings. Furthermore, regular cleaning and maintenance of your cutting tools can help prolong their lifespan and ensure that they function correctly.

This is something that we are regularly asked.

The toughest metal material to cut can vary depending on various factors such as the cutting method, tools used, and specific application.

However, some metals are generally known for their exceptional hardness and toughness, making them challenging to cut. Among these metals are:

Titanium: Titanium is an extremely tough metal that is commonly used in aerospace and medical industries due to its high strength-to-weight ratio. Its hardness and heat resistance render it difficult to cut, requiring specialised tools and techniques.

Hardened Steel: Hardened steel, such as tool steel or alloy steel that has undergone heat treatment, is known for its exceptional hardness and toughness. Cutting through hardened steel requires high-quality cutting tools, such as carbide or diamond-tipped blades.

Inconel: Inconel is a family of superalloys that are resistant to high temperatures, corrosion, and oxidation. It is commonly used in aerospace and chemical industries.

Stainless Steel: Stainless steel is a widely used material known for its corrosion resistance and durability. However, certain grades of stainless steel, particularly those with higher levels of hardness and alloy content, can be difficult to cut. We specialise in stainless steel materials of many types. We recommend stainless because it is affordable and very long lasting.

Cutting metal can seem intimidating, but with the right tools and techniques, it can be effortless.

Whether you’re using a metal cutting saw, plasma cutter, jigsaw, or hacksaw, there are a variety of ways to cut metal. It’s important to choose the right tool for your project and to prepare your workspace correctly before getting started. Remember always to prioritize safety by wearing protective gear and regularly maintaining your cutting tools. With these tips, you can confidently cut metal and tackle any project with ease.

If you have a specific size that you would prefer us to cut for you then please feel free to contact us anytime.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options