- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » How to Cut Aluminium Angle at Home: Tools and Techniques

Aluminium angle is one of the most versatile materials available for DIY enthusiasts and home improvement projects. With its lightweight nature, corrosion resistance, and excellent strength-to-weight ratio, aluminium angle can be used for a wide range of applications, from custom shelving brackets and furniture edging to framing and structural reinforcements. Whether you’re a professional builder or a DIY hobbyist, aluminium angle offers both durability and ease of handling, making it a popular choice for projects that require precision and resilience.

However, while aluminium is relatively easy to work with compared to other metals, cutting it accurately at home requires the right tools and techniques. Improper cutting methods can lead to rough edges, material warping, and unnecessary waste, affecting the quality of your final piece. With a few well-chosen tools and an understanding of cutting techniques, you can achieve clean, precise cuts on aluminium angle without the need for complex machinery.

In this guide, we’ll explore several methods for cutting aluminium angle, ranging from simple hand tools like hacksaws to power tools like mitre saws and angle grinders. We’ll provide practical tips for each technique, ensuring you have the knowledge to tackle your project confidently and safely. Let’s dive into the properties of aluminium angle and the specific challenges you might encounter when cutting it.

Overview of Aluminium Angle Properties

Aluminium angle is widely used in DIY and construction projects due to its impressive combination of lightweight, strength, and resistance to corrosion. Unlike steel, aluminium doesn’t rust, which makes it an ideal choice for both indoor and outdoor applications. Its angled shape — typically a 90-degree bend — adds rigidity without adding excessive weight, making it a practical material for structural and support purposes. Aluminium angle is also easier to transport and handle than heavier metals, further contributing to its popularity among DIYers and professionals alike.

In addition to its durability, aluminium angle is highly versatile. It can be used to create frames, reinforce structures, add aesthetic edges, or even form brackets for various mounting applications. Speciality Metals offers a range of aluminium angle sizes to suit different needs, allowing you to select the ideal dimensions for your specific project. However, while the material’s properties make it user-friendly, cutting it accurately requires attention to detail to avoid issues during the process.

Challenges in Cutting Aluminium

Despite its many advantages, aluminium can pose certain challenges when it comes to cutting. One of the main issues is that aluminium tends to warp if excessive heat is applied, especially during high-speed cutting. This warping can lead to inaccuracies and even compromise the material’s structural integrity. Additionally, aluminium is prone to developing burrs – rough, raised edges – when cut, which can make the finished piece look untidy and may even pose a safety hazard if not smoothed out.

Another common challenge is maintaining clean, straight cuts. Aluminium angle often needs to be cut precisely to fit specific applications, such as forming part of a frame or bracket. Achieving a smooth and accurate cut can be difficult without the right tools and techniques. Unlike cutting wood, where a simple saw may suffice, cutting aluminium requires special blades designed to handle metal without overheating or dulling quickly.

Safety First

Safety is paramount when working with any type of metal, and aluminium is no exception. Before starting any cutting project, it’s essential to set up a stable work area with a secure surface for clamping the aluminium angle. Make sure you’re equipped with the proper safety gear, including cut-resistant gloves, safety goggles, and ear protection. Aluminium fragments can be sharp, and metal cutting tools often generate a lot of noise, so protecting your hands, eyes, and ears is crucial.

In addition, ensure your workspace is clear of flammable materials and well-ventilated, as metal cutting can create sparks and fine aluminium dust. Having a stable workbench and clamps to secure the aluminium angle is also important to prevent movement during cutting, which can help you achieve a straighter, cleaner cut. By prioritising safety and preparation, you’ll set yourself up for a successful cutting process, whether you’re using a simple hacksaw or a more powerful tool like a mitre saw.

When it comes to cutting aluminium angle at home, selecting the right tool can make a significant difference in the ease, precision, and quality of your work. Depending on the thickness of the aluminium and the desired finish, various tools can be used, each with its own set of advantages and limitations. Here’s a look at some of the most commonly used tools for cutting aluminium angle sections, along with tips on how to get the best results from each.

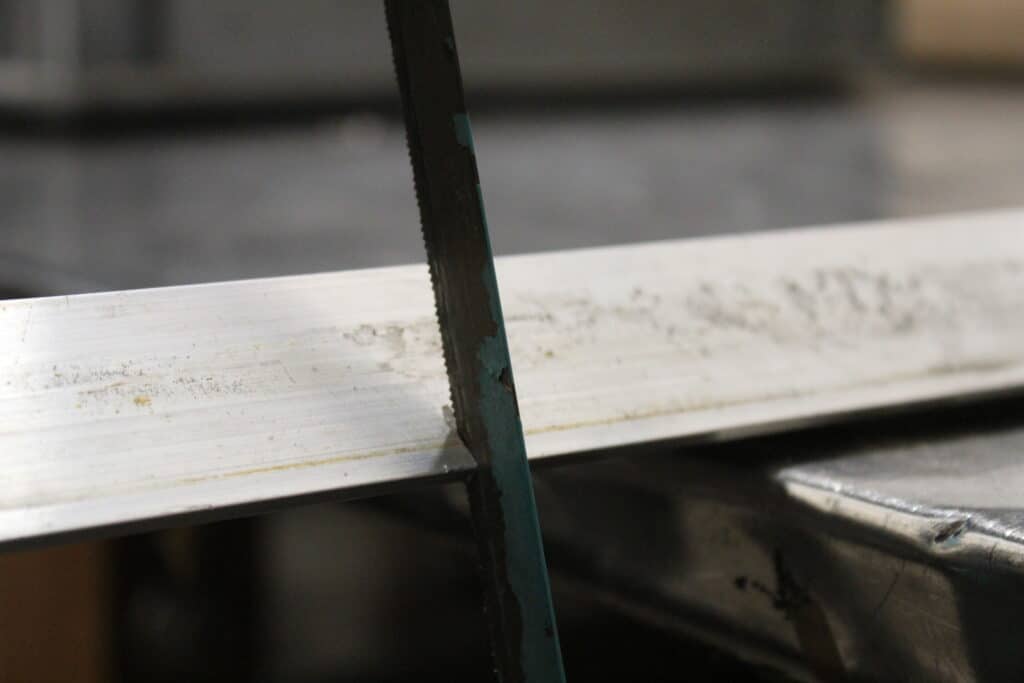

The hacksaw is a simple, handheld tool that’s perfect for small, straightforward cuts in aluminium angle. It offers good control, allowing you to guide the blade precisely along the cut line. However, using a hacksaw can be time-consuming, especially if you’re working with thicker sections of aluminium or making multiple cuts.

Pros: Low cost, excellent control, and minimal risk of overheating the material.

Cons: Time-consuming and physically demanding for thicker aluminium angles.

Tips for Usage: For the best results, use a fine-toothed blade with 18-24 teeth per inch (TPI). The higher TPI helps to minimise burring along the cut edge, leaving a cleaner finish. Secure the aluminium angle firmly in a vice or with clamps to keep it stable, and make slow, steady strokes to maintain control over the cut. Take breaks if necessary to prevent fatigue, as this can affect the quality of the cut.

Hand shears, often referred to as tin snips, are another tool that can be effective for cutting thinner aluminium angles, generally up to 1-2mm in thickness. They offer a quick and convenient way to make cuts without the need for power tools, but they are only suitable for relatively thin material. If not used carefully, hand shears can cause the aluminium to warp, particularly around the cut line.

Pros: Quick, quiet, and easy to use for thin aluminium; no electricity required.

Cons: Limited to thin aluminium; potential for warping if not used properly.

Tips for Usage: To achieve a clean cut, position the shears at the very edge of the aluminium angle and make slow, deliberate cuts, applying even pressure throughout.

Avoid rushing, as this can distort the material. For best results, use shears designed specifically for cutting aluminium or light metals. Avoid trying to cut thicker sections, as this can damage the tool and result in an uneven cut.

For thicker aluminium angles or projects involving larger quantities of material, power saws like a circular saw or a mitre saw are often the best choice. These tools offer speed and precision, making them ideal for more demanding cutting tasks. When using a power saw for aluminium, it’s crucial to equip it with a metal-cutting blade, preferably carbide-tipped, to achieve clean, smooth cuts.

Pros: Fast and efficient for thicker or larger aluminium pieces; ideal for precise cuts.

Cons: Requires careful handling and setup; risk of overheating the material if not used properly.

Tips for Usage: When cutting aluminium with a power saw, use a low feed rate to prevent overheating and reduce the risk of warping. Secure the aluminium angle firmly and make sure to wear protective eyewear, as power saws can create a lot of small metal chips. A metal-cutting lubricant or cutting fluid can also be applied to the blade to further reduce friction and ensure a smoother cut. Additionally, consider using a mitre saw with a guide to make angled cuts more easily and accurately.

The angle grinder is a versatile tool that can be used for quick cuts on thicker aluminium angles. It’s particularly effective for rough cuts, although it may leave a somewhat jagged edge that will require deburring. Angle grinders are a powerful option for cutting aluminium but require a steady hand to prevent over-grinding and maintain control.

Pros: Quick and effective for thicker materials; versatile for different angles and shapes.

Cons: Can leave rough edges; requires careful handling and can produce a lot of sparks and metal debris.

Tips for Usage: To cut aluminium angle with an angle grinder, use a metal-cutting disc and hold the grinder with both hands to maintain control. Position the grinder at a slight angle to avoid digging too deeply into the metal, and apply consistent, even pressure to make a smooth cut. Always wear safety goggles and gloves, as the grinder can create a lot of sparks and small metal fragments. Be mindful not to over-grind, as this can reduce the strength of the aluminium angle by removing too much material.

Each of these tools offers unique benefits and is suited to different types of cuts and aluminium thicknesses. Selecting the right tool for your specific project can help you achieve cleaner, more precise cuts while maintaining the integrity of the aluminium angle.

Whether you’re tackling a small DIY project or a more extensive home improvement job, using the appropriate tool will ensure the best results for your aluminium cutting needs.

When cutting aluminium angle at home, it’s essential to use the correct technique with each tool to ensure a clean, precise cut.

Here’s a step-by-step guide for each cutting method, along with tips for achieving professional-looking results:

Using a hacksaw is a straightforward approach for cutting aluminium angles, particularly for smaller projects or thinner sections. This method provides good control over the cut, but it requires patience and a steady hand.

Step 1: Secure the aluminium angle firmly in a vice or with strong clamps on a stable workbench. Ensuring the piece is secure will prevent movement while sawing, which is crucial for accuracy.

Step 2: Mark the cut line using a straight edge and a fine-tipped marker or scribe. Double-check your measurements to avoid mistakes.

Step 3: Begin sawing slowly along the marked line, keeping the saw blade perpendicular to the aluminium angle. Using a fine-toothed blade (18-24 TPI) will help reduce burrs and create a cleaner cut.

Step 4: Apply even, steady pressure as you saw, and avoid twisting or bending the material. Hacksaws can be physically demanding, so take breaks if needed to maintain precision.

Tip: After completing the cut, use a metal file to smooth any rough edges left by the hacksaw. This will ensure a cleaner, more professional finish.

Hand shears, also known as tin snips, are a quick and convenient tool for cutting thinner aluminium angles (up to about 2mm). They allow for relatively easy and clean cuts, but require careful handling to avoid warping the metal.

Step 1: Place the aluminium angle on a flat, stable surface for support. This will make it easier to control the cut and prevent accidental bending.

Step 2: Mark the cut line with a marker, ensuring that your measurement is precise.

Step 3: Use the hand shears to cut along the marked line, applying steady, even pressure. Avoid cutting too quickly, as this can cause the aluminium to warp or bend.

Step 4: Smooth any rough edges with a metal file or sandpaper to give the cut a clean finish.

Tip: When using hand shears, position the blades at the very edge of the aluminium angle and avoid cutting near the centre of the material, as this can lead to deformation.

Power saws, such as mitre saws or circular saws equipped with a metal-cutting blade, are ideal for thicker or larger aluminium angle sections. These tools provide quick, precise cuts but require careful setup and handling.

Step 1: Secure the aluminium angle on the saw’s table, aligning the blade with the marked cut line. Ensure the angle is clamped firmly to avoid any movement during cutting.

Step 2: Lower the saw blade slowly onto the aluminium angle to initiate the cut. Avoid pressing down too hard; let the blade’s weight and power do the work.

Step 3: Maintain a slow, steady feed rate as you push the material through the blade. Pushing too quickly can lead to rough edges and increase the risk of overheating, which may warp the metal.

Step 4: Once the cut is complete, inspect the cut edge for any burrs and smooth as necessary with a file or sandpaper.

Tip: A carbide-tipped blade specifically designed for metal will produce the cleanest cuts. Additionally, applying a small amount of cutting lubricant can help reduce friction and prolong the life of the blade.

An angle grinder is a versatile tool that can be used for quick cuts on thicker aluminium angle sections. Although it may leave a rough edge, this method is effective for fast, rough cuts and is suitable for heavier-duty projects.

Step 1: Secure the aluminium angle in a vice or with clamps on a stable surface. This is essential for maintaining control over the cut and ensuring your safety.

Step 2: Mark the cut line with a marker and align the grinding wheel with the line. Position the grinder at a slight angle to start the cut.

Step 3: Start grinding slowly along the marked line, keeping the grinder steady to avoid over-cutting or damaging the aluminium angle. Keep both hands on the tool for control.

Step 4: Once the cut is complete, smooth any rough edges with a file or sandpaper to finish the surface.

Tip: For the cleanest results, use a metal-cutting disc on your angle grinder. Move steadily along the line, applying even pressure and avoiding excessive force, as this can damage the aluminium.

When cutting aluminium angle at home, achieving a clean cut without causing any warping can be a challenge. Here are some essential tips to help you get professional results every time.

Blade Selection:

Choosing the right blade is crucial for cutting aluminium smoothly. A fine-toothed blade, typically with 18-24 teeth per inch (TPI), works well with hand tools like hacksaws, as it reduces the chance of burring. For power tools like mitre saws or circular saws, opt for a metal-cutting blade or a carbide-tipped blade specifically designed for aluminium. These blades are designed to handle the metal’s density and minimise rough edges, ensuring a cleaner finish.

Cooling Techniques:

Aluminium has high thermal conductivity, meaning it heats up quickly during cutting. Excessive heat can cause the metal to warp, which compromises both the appearance and functionality of the cut piece. To prevent overheating, take regular breaks during the cutting process, especially when using power tools. For thicker aluminium, consider applying a cooling lubricant to the cutting area, which helps dissipate heat and reduces the risk of warping. This is especially useful for continuous cutting on larger sections.

Edge Smoothing:

After cutting, aluminium edges may have burrs or rough spots. Use a metal file or fine-grit sandpaper to smooth these edges. Filing in one direction, rather than back and forth, will create a cleaner, more professional finish. For smaller pieces, you might find a deburring tool helpful for precise edge finishing. Smoothing the edges not only improves the appearance but also reduces the risk of injury from sharp metal edges.

Aluminium angles are versatile and suitable for a wide range of projects, from DIY home improvements to functional repairs and outdoor applications. Here are some creative and practical ways to use aluminium angle sections.

DIY Home Projects:

Aluminium angle sections are ideal for creating custom shelving, edging for tables, or picture frames. Their lightweight yet sturdy properties make them perfect for constructing brackets for lightweight fixtures, such as bookshelves or small decorative items. The smaller aluminium angles in our range, like the 20mm x 20mm or 25mm x 25mm sections, are particularly useful for these types of projects, providing support without adding significant weight.

Automotive and Mechanical Repairs:

In automotive and mechanical settings, aluminium angle can be used to reinforce vehicle parts or create custom brackets and supports. It’s particularly useful for non-load-bearing applications that require corrosion resistance. For instance, a 50mm x 50mm or 40mm x 40mm angle section can be used to mount components in the engine bay or create supports for vehicle interiors. The metal’s natural resistance to rust also makes it suitable for use in places exposed to moisture.

Gardening and Outdoor Projects:

Thanks to aluminium’s natural resistance to corrosion, it’s an excellent choice for outdoor applications. Aluminium angle can be used to build weather-resistant frames, plant stands, and garden borders or edging. The 60mm x 60mm x 6mm section is particularly suitable for larger, more robust outdoor structures. Additionally, aluminium angle is lightweight, making it easy to transport and install for temporary or movable garden projects.

Here are answers to some common questions about cutting aluminium angle, which can help you choose the right tools and techniques for your project.

What is the best tool for beginners?

For beginners, a hacksaw with a fine-toothed blade is the most straightforward tool to use. It offers control and precision without the need for extensive safety equipment. Hand shears can also be effective for thin aluminium (1-2mm).

How do I prevent burrs when cutting?

Using a fine-toothed blade helps minimise burrs. For the cleanest finish, cut slowly and steadily, and use a metal file or sandpaper to smooth out any rough edges afterwards.

Can I use a wood saw to cut aluminium angle?

It’s not recommended to use a wood saw for cutting aluminium. Wood saw blades have a low tooth count and lack the necessary sharpness to handle metal. Instead, use a metal-cutting blade or a carbide-tipped blade designed for cutting aluminium.

What thicknesses are suitable for hand tools vs. power tools?

Hand tools, like hacksaws and shears, are best suited for thinner aluminium angles up to around 3mm. For thicker sections, such as 4mm or more, power tools like a mitre saw or angle grinder are more effective for achieving clean, consistent cuts.

This guide has covered essential tips and techniques for cutting aluminium angle at home, highlighting the importance of selecting the right tools and applying appropriate methods for clean, accurate cuts.

Whether you’re using a hacksaw, hand shears, power saw, or angle grinder, each tool offers unique advantages that can make the cutting process efficient and safe. We’ve also explored practical ways to achieve clean edges, avoid warping, and create professional finishes, ensuring your aluminium angles are ready for any project.

At Speciality Metals, we offer a comprehensive range of aluminium angles in various sizes and thicknesses to suit a wide array of applications, from lightweight DIY home improvements to robust construction projects. Our selection includes options like 20mm x 20mm for delicate tasks, up to 60mm x 60mm for heavy-duty needs. Whatever your requirements, our high-quality aluminium angle products provide durability, strength, and versatility.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options