- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Combining Different Metals: Which Alloys Work Best Together?

Combining different metals can lead to innovative solutions in fabrication, architecture, and industrial applications. However, it’s not as simple as welding two materials together—understanding how different alloys interact is essential for creating long-lasting, corrosion-resistant structures.

At Speciality Metals, we supply a wide range of metal products, including stainless steel, aluminium, copper, and mild steel. Many customers ask whether these metals can be used together in a single project. The short answer is: yes—but only when done correctly.

This guide explores the science, practical considerations, and best combinations when working with mixed metals, giving you the confidence to plan hybrid-material projects effectively.

In many scenarios, using more than one type of metal offers design flexibility and enhances performance. For example:

Aluminium is lightweight and corrosion-resistant—ideal for reducing structural weight.

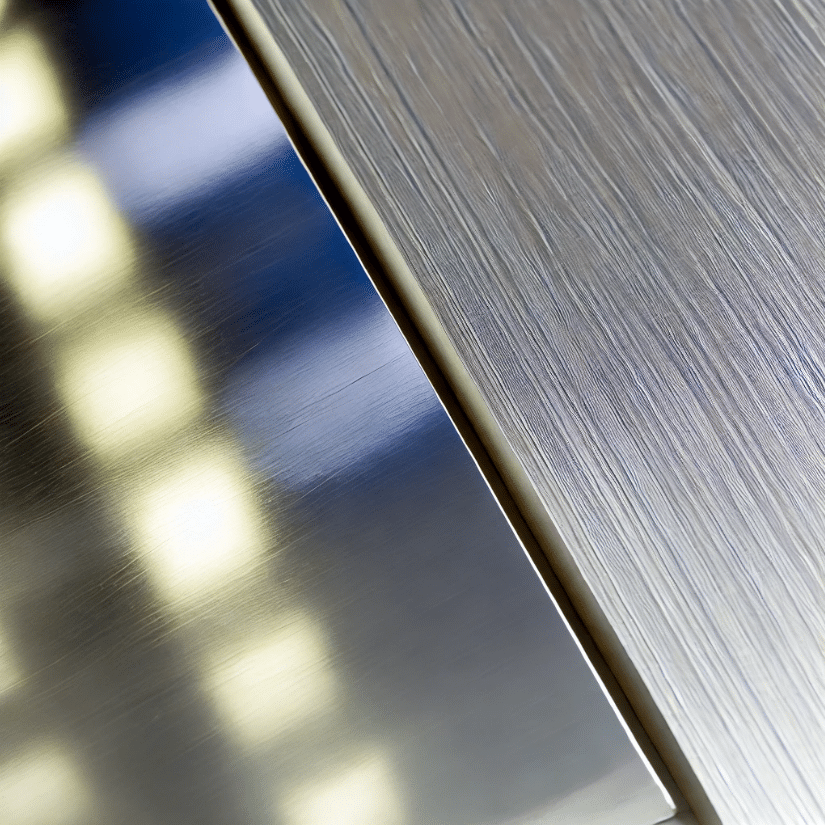

Stainless steel offers superior strength and aesthetic appeal.

Copper has excellent electrical and thermal conductivity.

✔ When these metals are paired strategically, they can deliver the benefits of each without compromising overall performance.

💡 Example: A structure requiring both strength and reduced weight might pair a stainless steel frame with aluminium sheeting.

That said, combining different metals requires careful planning to avoid issues like galvanic corrosion or differential expansion.

To make successful use of multiple metals, consider the following:

✔ Electrical potential difference – Dissimilar metals placed in contact can create a galvanic cell in the presence of moisture, leading to corrosion.

✔ Thermal expansion – Some metals expand more than others when heated. This can cause warping or cracking if not considered in the design.

✔ Mechanical compatibility – Metals should have similar hardness levels when being joined mechanically to avoid uneven wear.

✔ Environmental exposure – In marine, humid, or acidic environments, some metals corrode more quickly. Choose combinations that can withstand local conditions.

✔ Joining method – Welding, bolting, and adhesives each react differently to combinations of metals. Ensure the joining method suits both materials.

When two dissimilar metals are electrically connected in the presence of an electrolyte (such as water), the more reactive metal corrodes faster. This phenomenon is known as galvanic corrosion.

| Metal | Galvanic Position |

|---|---|

| Zinc | Highly Reactive |

| Aluminium | Reactive |

| Mild Steel | Moderate |

| Stainless Steel 304 | Low Reactivity |

| Copper | Very Low Reactivity |

Metals far apart on the scale (e.g., aluminium and copper) are more likely to cause galvanic corrosion when combined without isolation.

💡 Tip: Use plastic washers or coatings to physically separate dissimilar metals and slow down galvanic action.

Some metal combinations have proven success in the field:

Aluminium + Stainless Steel – Common in transportation and modern architecture. Needs insulation at joints.

Mild Steel + Copper – Occasionally used in roofing where conductivity and strength are required.

Stainless Steel + Brass – Seen in decorative or high-end fixtures, such as handles and splashbacks.

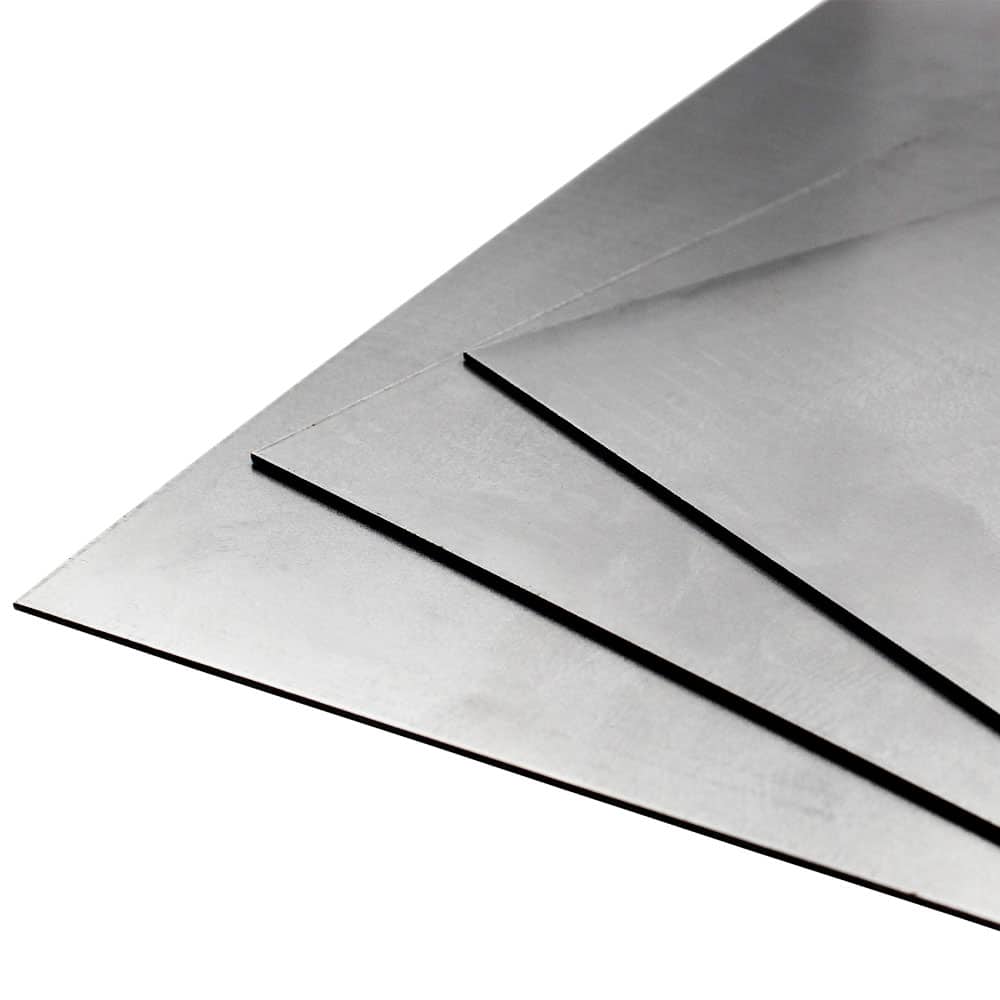

Mild Steel + Aluminium – Used in framed panels or enclosure systems.

Avoid pairing copper directly with aluminium in electrical applications without appropriate separation, as copper is significantly more noble and can cause the aluminium to corrode rapidly.

While many combinations are safe, some should be avoided unless absolutely necessary and with full mitigation steps in place.

✘ Copper + Aluminium – High galvanic potential; not ideal in wet or exposed conditions.

✘ Stainless + Carbon Steel – Can cause carbon steel to rust when in direct contact with moisture.

✘ Zinc + Copper – The zinc corrodes rapidly in mixed assemblies.

When engineered properly, combining different metals offers unique advantages in areas such as:

Vehicle chassis design – Stainless steel frames with lightweight aluminium panels.

Commercial kitchens – Copper piping with stainless steel surfaces for both hygiene and conductivity.

Architectural cladding – Aesthetically contrasting panels made from different metals.

Solar and renewable energy systems – Aluminium brackets with stainless steel fasteners.

These applications benefit from weight savings, corrosion resistance, or improved performance, depending on the metals used.

At Speciality Metals, we stock a wide range of products ideal for projects involving different metals, including:

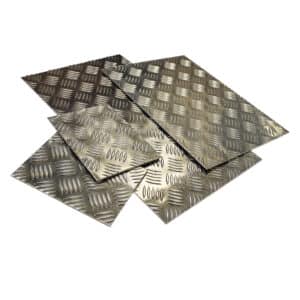

Aluminium Sheets – Perfect for lightweight panels, cladding, and DIY fabrication.

Stainless Steel 304 Box Section – Combines strength and corrosion resistance for structural use.

Mild Steel Round Tubes – Versatile and easy to weld, ideal for framework.

Copper Sheets – Often used for conductivity or decorative finishes.

Stainless Steel Fasteners – Work well with most metals when combined with insulation or coatings.

By selecting the right products and pairing them carefully, you can create durable, cost-effective, and visually appealing results.

Combining different metals in a single project opens up endless possibilities in terms of design, durability, and performance. However, it requires careful planning, material knowledge, and proper execution. Understanding the potential for galvanic corrosion, thermal expansion, and mechanical compatibility is key to successful outcomes.

At Speciality Metals, we supply a wide selection of metal products to support your mixed-metal designs—whether you’re building railings, custom enclosures, or architectural elements.

🔗 For expert advice or to explore our product range, visit www.smetals.co.uk today.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options