- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

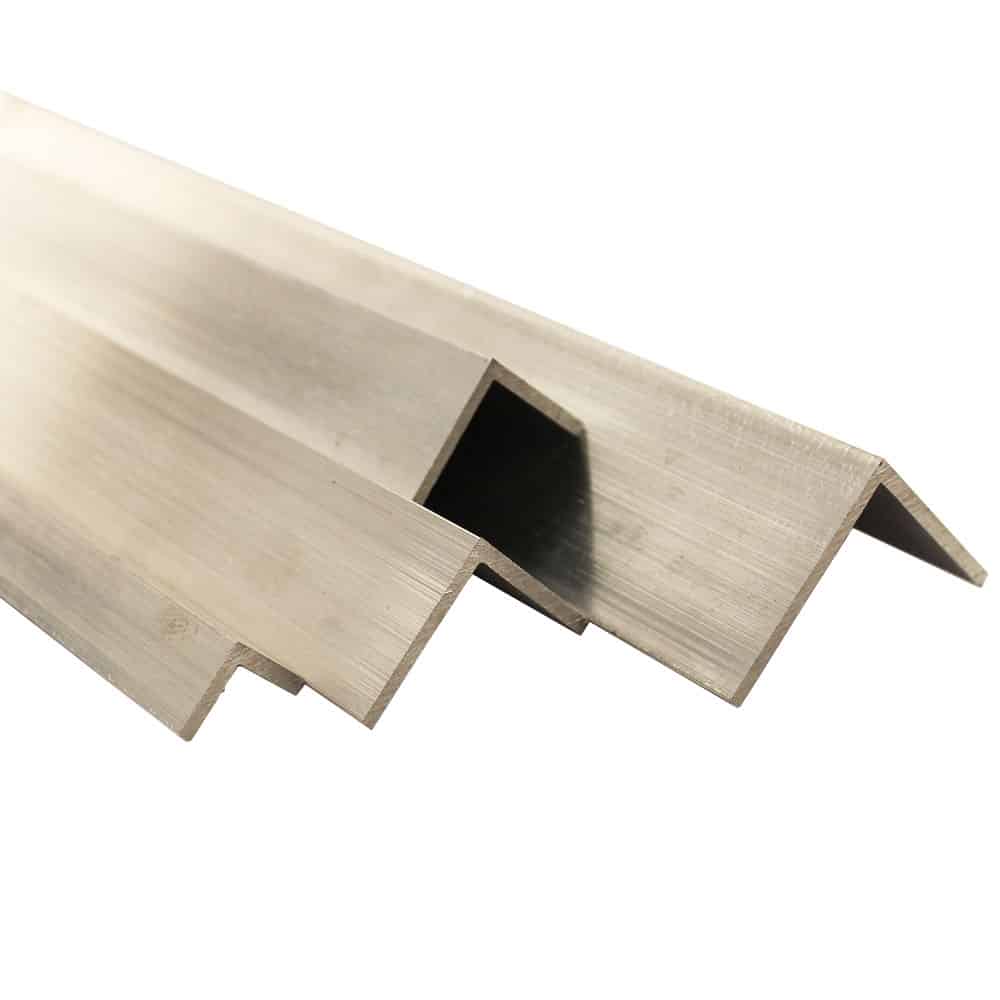

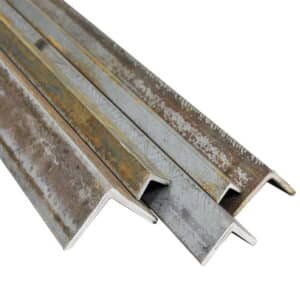

Home » Aluminium vs. Steel Angle: A Comprehensive Comparison

In the vast world of construction and design, the decision to use aluminium or steel angles remains a longstanding debate.

Each metal offers unique attributes and benefits, depending on its use. In this article, we will delve deep into the characteristics, pros, cons, and applications of both materials.

We also offer an array of products in both aluminium and steel that you can explore through the links throughout this article. We have also added a few examples to the ‘Related Products’ bar of this page.

Let’s get into it…

Given its lightweight nature and flexibility, aluminium is widely used in:

View our 50.8mm x 50.08mm x 3.175mm aluminium angle and other sizes

Thanks to its strength and durability, steel is commonly found in:

Aluminium and steel production have evolved dramatically over time. It was the Hall-Héroult process for aluminium production that revolutionized the industry and made aluminium more accessible to the masses in the 19th century. Due to its difficulty of extraction, aluminium was previously considered more valuable than gold. Today, the energy-intensive nature of this process means aluminium often has a higher initial cost than steel.

Due to its production process, aluminium is generally more expensive than steel. However, due to its longevity and corrosion resistance, it often offers better value in the long run. Due to its abundance, steel, however, is usually more affordable in its basic form.

Aluminium, however, has an edge when it comes to sustainability. Compared to its initial production, recycling aluminum consumes just 5% of the energy. The value of recyclable materials like aluminum continues to rise as societies become more eco-conscious. Aluminium’s recycling efficiency not only reduces costs in the long run, but also positions it as a green and sustainable material.

Both metals are recyclable from a sustainability perspective. Recycling aluminum consumes significantly less energy than its initial production, making it an environmentally friendly process.

In spite of the fact that both metals have their own advantages, the choice of which metal to use is highly dependent on the project requirements. Steel is your go-to material if you’re looking for strength and durability. When it comes to projects that require lightweight materials that are corrosion resistant, aluminium takes the crown when it comes to lightweight materials.

Remember, it’s not always about which metal is better overall, but which is better suited for your specific needs. Explore our vast range of aluminium and mild steel angle products to find the perfect fit for your project.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options