- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » A Deep Dive into Durability: Stainless vs Aluminum Sheet

When choosing materials for projects that require sheet metal, two of the most popular options are stainless steel vs aluminium sheet. There are advantages and challenges to each material, making the decision between stainless steel and aluminium an important one for manufacturers, engineers, and designers. The purpose of this blog is to share the characteristics, uses, and cost-effectiveness of both materials so you can make an informed decision when you are deciding what to use for your next project.

Stainless steel is an iron-based alloy celebrated for its corrosion resistance, attributed to a chromium content of at least 10.5%. This chromium creates a protective layer of chromium oxide, preventing surface and internal corrosion. It often includes other elements like nickel, molybdenum, and titanium, enhancing its strength, ductility, and formability.

There are five primary types of stainless steel, each tailored for different uses. Austenitic stainless steels, the most prevalent type, offer excellent corrosion resistance and formability, making them suitable for kitchenware, industrial equipment, and architecture. Ferritic varieties, which are magnetic due to lower nickel content, are used in automotive parts and appliances for their good corrosion resistance. Martensitic stainless steels, distinguished by their hardness, cater to applications needing high strength and wear resistance, like surgical tools and cutlery.

Aluminum is a silvery-white, lightweight metal known for its softness, ductility, and exceptional corrosion resistance, making it ideal for applications requiring weight reduction, such as aerospace and transportation. This corrosion resistance is due to its ability to form a protective aluminum oxide layer upon exposure to air.

There are various grades and types of aluminum, each tailored for different uses based on alloying elements.

6061 aluminum, a widely used alloy containing magnesium and silicon, offers a strong balance of strength, weldability, and corrosion resistance, suitable for automotive parts and construction materials.

7075 aluminum, distinguished by its high strength thanks to zinc and magnesium, is used for stressed structural parts in aerospace and defense, like aircraft fittings and gears.

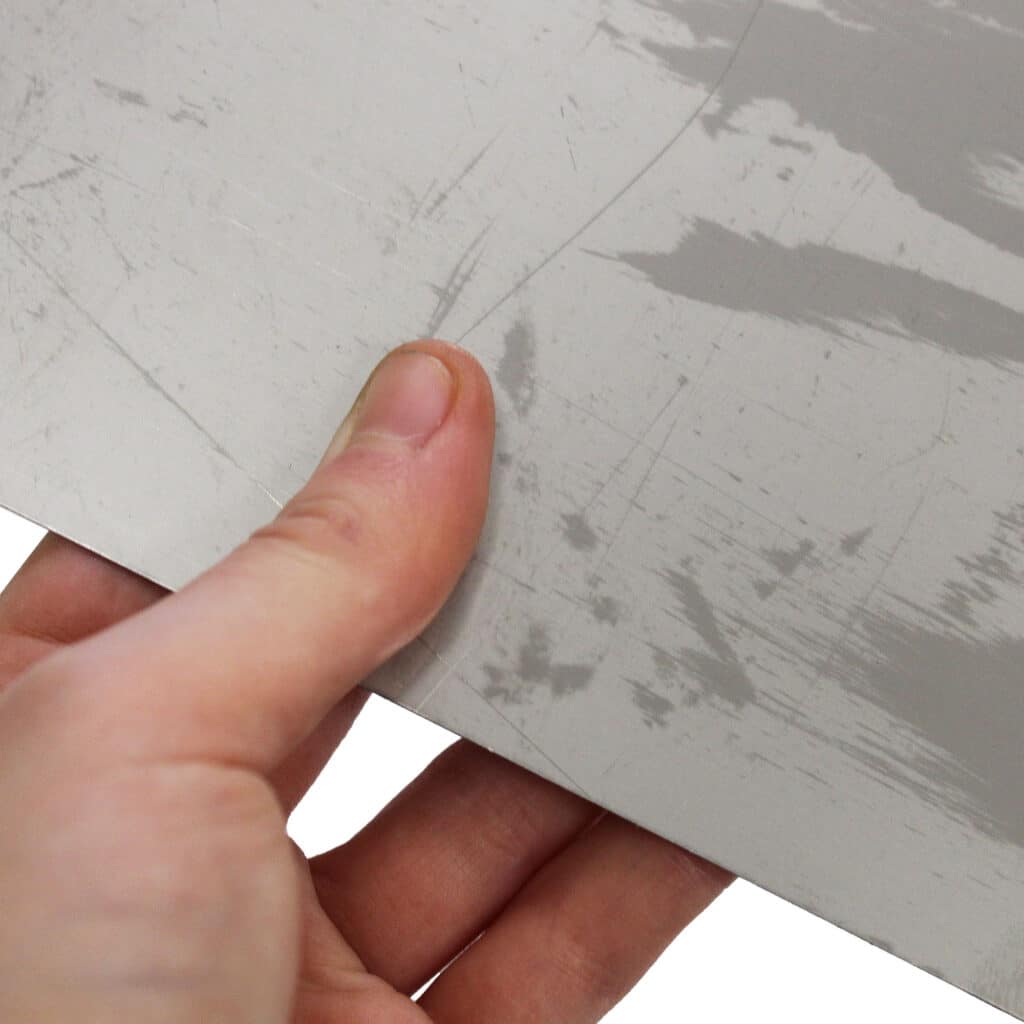

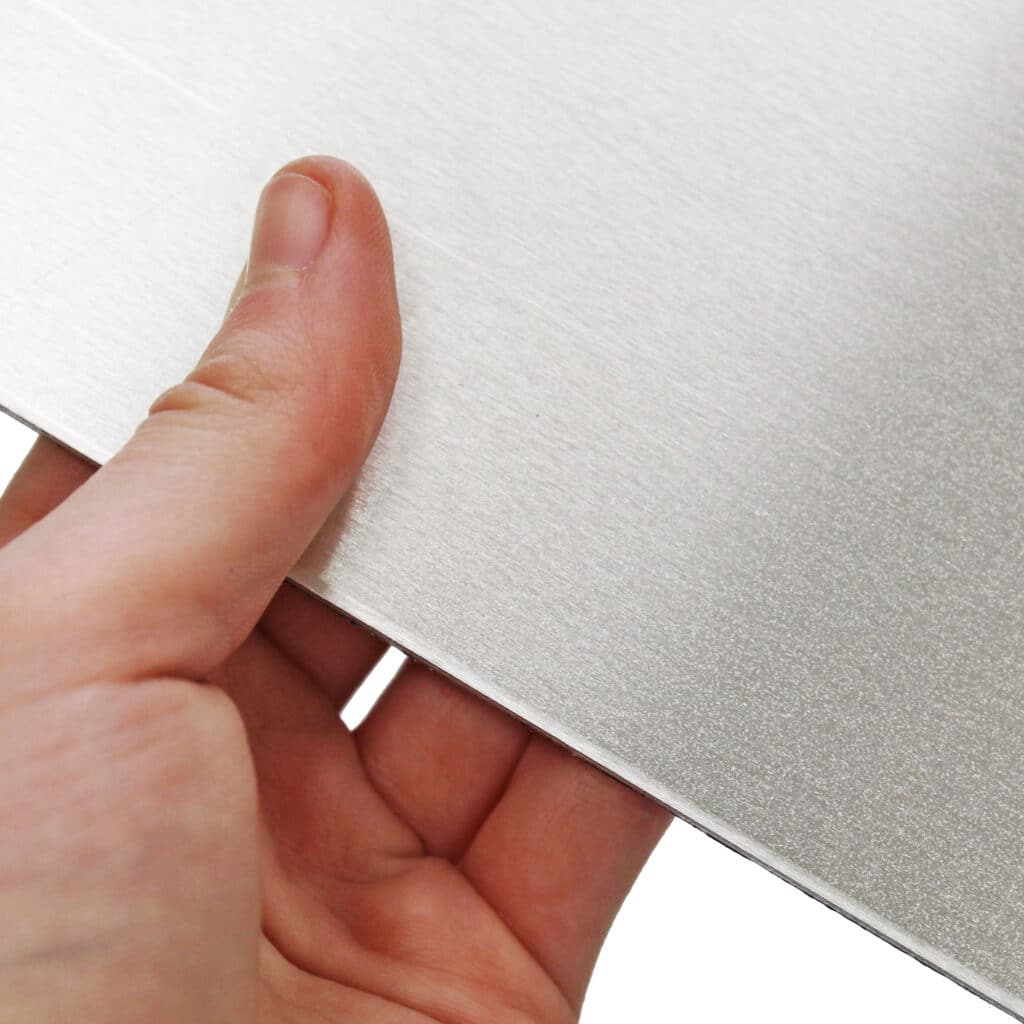

Stainless Steel: Known for its exceptional durability, stainless steel is highly resistant to corrosion, rust, and staining. This makes it an excellent choice for environments that are susceptible to moisture or chemicals. Its resilience also means it’s more likely to retain its appearance and structural integrity over time, even in harsh conditions.

Aluminium: While aluminium is naturally corrosion-resistant and does not rust, it is generally softer and less durable than stainless steel. However, when treated with anodizing, the surface of aluminium can become significantly harder and more resistant to corrosion. This treatment can extend its lifespan and enhance its performance in challenging environments.

Stainless Steel: Stainless steel is heavier than aluminium, which may be a consideration in projects where weight is a critical factor. However, its strength-to-weight ratio is very favorable, making it a preferred choice for heavy-duty applications where strength is paramount.

Aluminium: Aluminium’s most notable characteristic is its low density, making it lightweight without sacrificing too much in terms of strength. This lightness makes aluminium an ideal choice for applications where reducing weight is beneficial, such as in automotive and aerospace industries.

Stainless Steel: Stainless steel is not a good conductor of electricity or heat compared to aluminium. This characteristic can be advantageous or disadvantageous depending on the application. For instance, it is beneficial in applications that require minimizing energy loss through conductivity.

Aluminium: Aluminium is a superior conductor of heat and electricity. This makes it an excellent choice for electrical applications and cookware, where efficient heat distribution is crucial.

Stainless Steel: Generally, stainless steel is more expensive than aluminium, primarily due to its composition and durability. However, considering its longevity and low maintenance requirements, stainless steel can be a cost-effective choice for long-term projects.

Aluminium: Aluminium is typically less expensive than stainless steel, making it a budget-friendly option for a wide range of applications. However, it may require more maintenance or replacement over time, which can affect its overall cost-effectiveness.

Stainless Steel: With its sleek and modern appearance, stainless steel can offer a more sophisticated look. It’s particularly popular in kitchen appliances, architectural elements, and automotive detailing.

Aluminium: Aluminium has a more matte finish compared to the shiny appearance of stainless steel. This can be advantageous in projects where glare is a concern or where a more subdued appearance is preferred.

| Aspect | Stainless Steel Pros | Stainless Steel Cons | Aluminum Pros | Aluminum Cons |

|---|---|---|---|---|

| Corrosion Resistance | Excellent corrosion resistance due to chromium oxide layer. Good for harsh environments. | Costlier materials and treatments may be required for extreme conditions. | Forms a protective aluminum oxide layer, offering good corrosion resistance. Good for a wide range of uses. | May require anodizing for enhanced corrosion resistance in extreme environments. |

| Strength | High strength, especially in martensitic and duplex grades. Suitable for heavy-duty applications. | Heavier, which might be a drawback in applications where weight is a critical factor. | Lower density than stainless steel, offering a good strength-to-weight ratio. Ideal for weight-sensitive applications. | Generally, lower strength than stainless steel but can be alloyed for higher strength. |

| Weight | Heavier, offering robustness for structural applications. | Not suitable for applications where lightweight materials are preferred. | Lightweight, advantageous for aerospace, automotive, and transport industries. | Less structural strength than some heavier materials. |

| Conductivity | Poor conductor of heat and electricity, beneficial in minimizing energy loss. | May not be suitable for applications requiring good conductivity. | Excellent conductor of heat and electricity, suitable for electrical and heat-exchange applications. | High thermal and electrical conductivity may be a disadvantage in certain applications. |

| Cost-effectiveness | Durable and low maintenance, potentially more cost-effective over the long term. | Initial costs can be higher than aluminum. | Generally less expensive upfront, making it cost-effective for various applications. | May require more maintenance or replacement over time, affecting long-term costs. |

| Aesthetics | Offers a sleek and modern look. Popular in architecture and kitchen appliances. | — | Offers a matte finish, which can be preferred for reducing glare and achieving a specific aesthetic. | — |

| Applications | Used in kitchen utensils, industrial equipment, surgical instruments, and architectural structures. | Limited applications where non-magnetic or lighter materials are required. | Used in automotive parts, construction materials, aerospace and defense industries for stressed structural parts. | Not ideal for applications requiring the utmost strength. |

The choice between stainless steel and aluminium ultimately depends on the specific requirements of your project. There are many factors that go into this decision, including the environment, weight, strength, conductivity, cost, and aesthetics. Stainless steel is often the best choice for projects that require durability and corrosion resistance. Aluminum, on the other hand, may be a better option if weight and cost are more important. You can ensure durability, efficiency, and aesthetic appeal by carefully weighing the properties of stainless steel and aluminium before selecting the material.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options