- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

£9.95 – £31.99 inc VAT

Secure payments taken with:

This website is secured:

£ MULTIBUY SAVINGS – Order 3 For 10% Off

✔ Specialists In Rapid Shipments Of Any Size

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

£ Check Out Our Clearance Listing For Savings

@ ☏ Bespoke Cuts & Larger Quantities Available

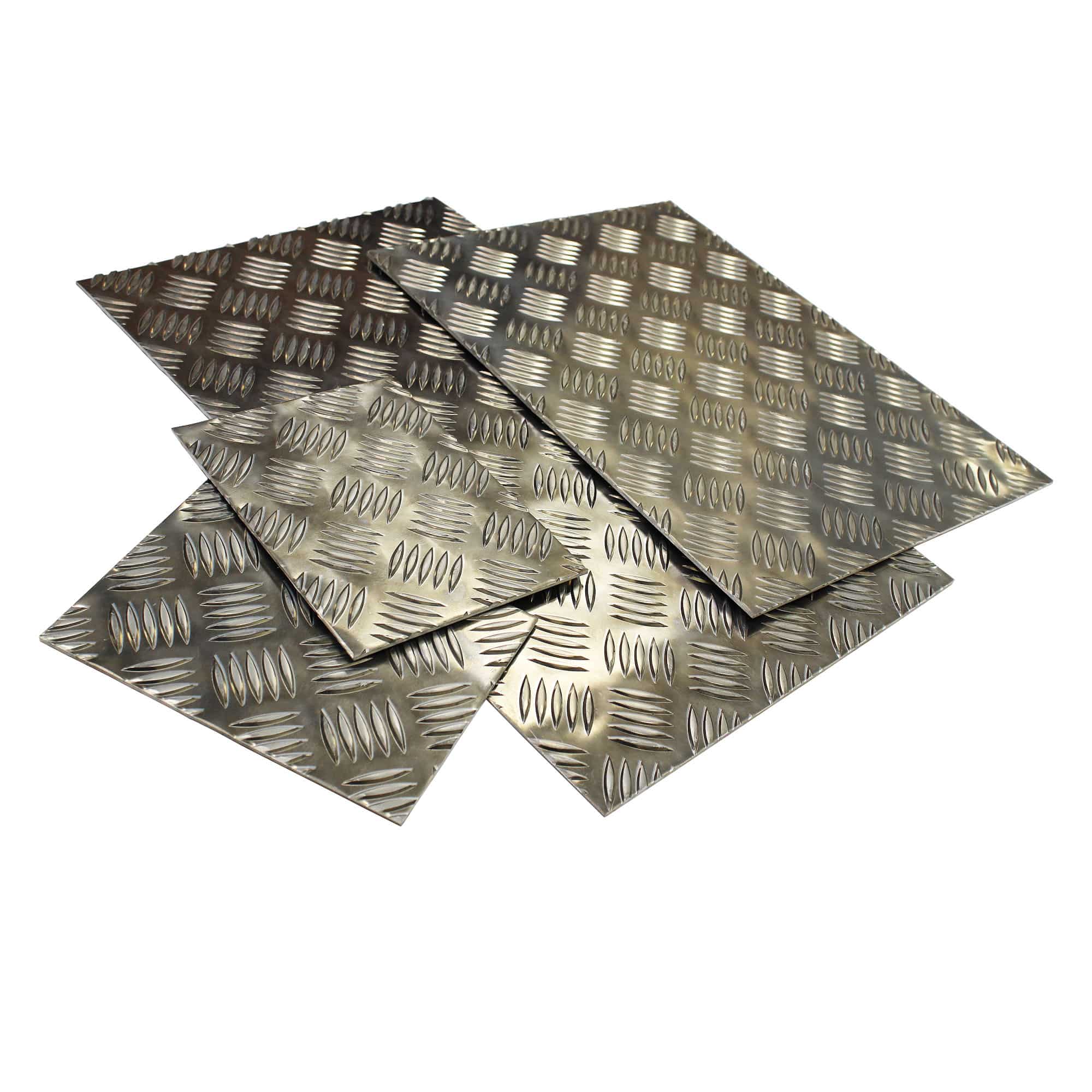

Specialty Metals offers top quality 1.5mm Thick 1050 Grade Aluminium Metal Sheets in various sizes to suit different applications. They are flexible, corrosion-resistant, and reflect light, making them an excellent material for projects in architecture, interior design, construction, and manufacturing. In addition to being durable and lightweight, they are also recyclable, making them eco-friendly and cost-effective. Moreover, the UK supply of these metal sheets allows for easy and convenient access to the product, ensuring timely delivery. Whether for a large industrial project or a small DIY task, these metal sheets are reliable and effective.

We offer a wide selection of aluminium metal sheets online from trusted mills within the UK. Providing high-quality, low-priced aluminium sheet products to UK businesses and the general public, Speciality Metals is a leading aluminium metals supplier.

Our aluminium sheeting, also known as aluminium plate, is supplied in Grade 1050 with a blue/silver appearance and a reflective finish. A popular grade of sheet metal, Grade 1050 is suitable for general sheet metal applications that require moderate strength and light weight. Aluminium plates are lightweight. In comparison to steel sheets, aluminium sheets weigh about a third less than steel sheets. In addition, the metal is resistant to corrosion, which is a common problem with most metals when they are exposed to oxygen. Compared to other metals, aluminium is unique in that it naturally develops a protective oxide coating, which makes it highly resistant to corrosion. Sheets made of aluminium are also ductile. Considering its density and low melting point, this material is easily bent and shaped to fit any shape.

Furthermore, it is 100% recyclable and sustainable. As a result of the recycling process, remelting aluminium sheet requires a minimal amount of energy. There are many industries that can benefit from aluminium sheet. As a result of its lightweight nature, it is ideal for a variety of applications. Due to its corrosion-resistant properties, aluminium sheet is also ideal for use in the construction of windows, roofs, and other projects. Food and beverage packaging often uses this material since it is impermeable and odourless.

Quick product details:

Sheet metal is also available in mild steel and stainless steel.

Speciality Metals is known to be the United Kingdom’s best up-and-coming small-quantity metal company.

Furthermore we stock a vast range of plain sheet plate options that compliment our mesh range perfectly.

Over 50,000 customers of Specialty Metals are provided with fast, friendly customer service every year. We’re the place to try when you need metal of any shape and size. We’re based in Warrington, UK. We pride ourselves on our rapid turnaround and a large range of options.

It is possible to bend aluminium metal sheets. However, the method and process for bending aluminium sheet metal is different than that of other metals, due to its unique properties and characteristics. Aluminium sheet metal is relatively soft and malleable, which makes it easy to bend and shape, but it also means that it can be more prone to cracking or breaking if not handled properly.

There are several methods for bending aluminium sheet metal, including:

When bending aluminium sheet metal, it is important to use the right tools and equipment, and to follow the manufacturer’s instructions and guidelines to ensure that the sheet is not damaged during the bending process. Additionally, it is important to use the correct bending radius, and to use the proper lubricant to prevent the sheet from cracking or breaking.

The choice of thickness depends on the application’s requirements, including structural integrity, weight constraints, and durability. Thin sheets (e.g., 0.5mm-3mm) are ideal for lightweight applications, while thicker sheets (e.g., 6mm-25mm) are suitable for structural components. Sheets with greater strength and rigidity are suitable for heavy-duty applications, whereas thinner sheets are more flexible and lighter, ideal for projects with weight restrictions or complex forming requirements. Consider cost considerations and seek expert guidance if necessary. Tests and prototypes can help validate your choice before full-scale production begins. Ultimately, the right thickness depends on the unique demands of your project.

Aluminum metal sheets are manufactured through a rolling process starting with aluminum ingots. The ingots are heated and passed through rolling mills to gradually reduce the thickness, creating flat sheets of aluminum. Optional steps like annealing or surface treatments, such as anodizing, may be applied based on the intended application. Rigorous quality control ensures the sheets meet specified standards. Once manufactured, the aluminum sheets are cut to size, carefully packaged, and distributed to various industries for use in diverse applications.

Aluminum sheets are protected from corrosion through a natural oxide layer that forms on the surface when exposed to air. This thin and transparent oxide layer acts as a barrier, preventing direct contact between the metal and corrosive agents. Additionally, manufacturers may apply surface treatments to enhance the sheets’ corrosion resistance further. One common method is anodizing, where the aluminum sheet is subjected to an electrolytic process that thickens the protective oxide layer. Another approach is applying protective coatings or paints that act as a physical barrier against environmental elements. By combining the inherent oxide layer and additional surface treatments, aluminum sheets become highly resistant to corrosion, making them ideal for outdoor and marine applications, as well as other environments prone to moisture and chemical exposure.

Check out our recent article ‘Frequently Asked Questions About Aluminium Sheet Metal’ for a deeper dive into all things aluminium sheeting.

We are also very proud of our ever expanding YouTube channel.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact us today if you have any questions at all. We are always really keen to help in any way that we can.

We are also very proud of our highly popular eBay store, check us out there too.

Thank you for checking out our product.

£13.99 – £30.49 inc VAT

£15.99 – £61.99 inc VAT

£13.99 – £30.49 inc VAT

£15.99 – £61.99 inc VAT

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options