- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Square Hole Perforated Sheet: Uses and Benefits

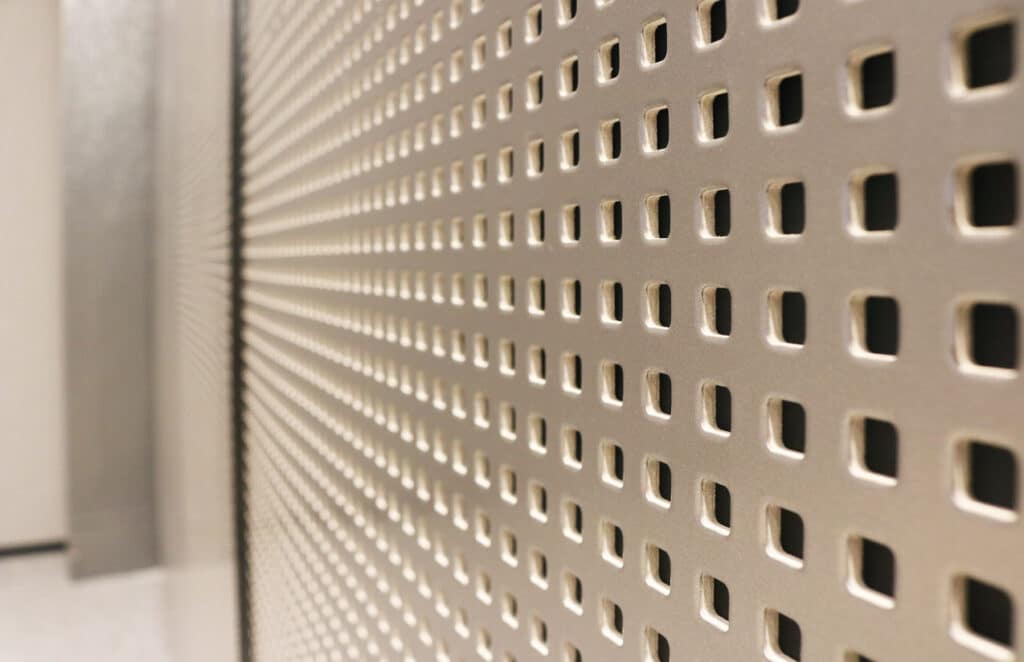

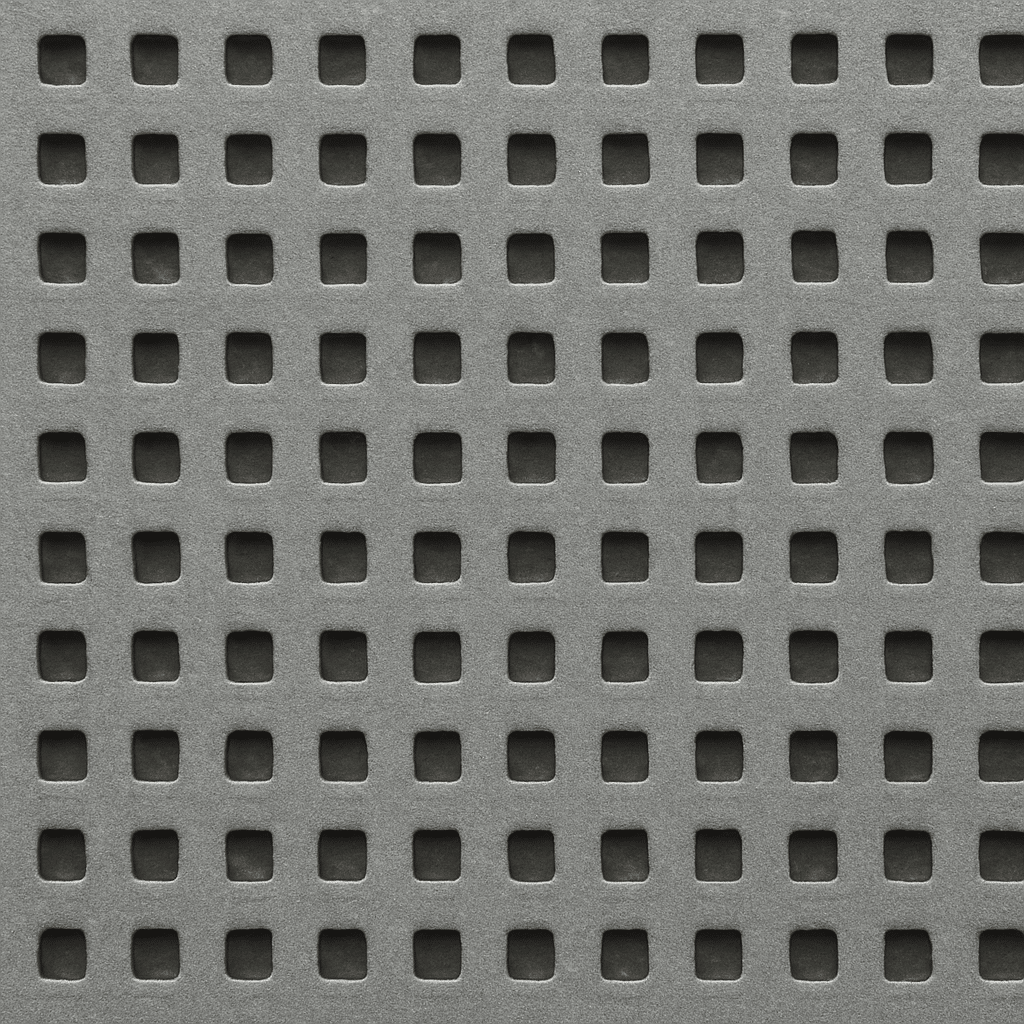

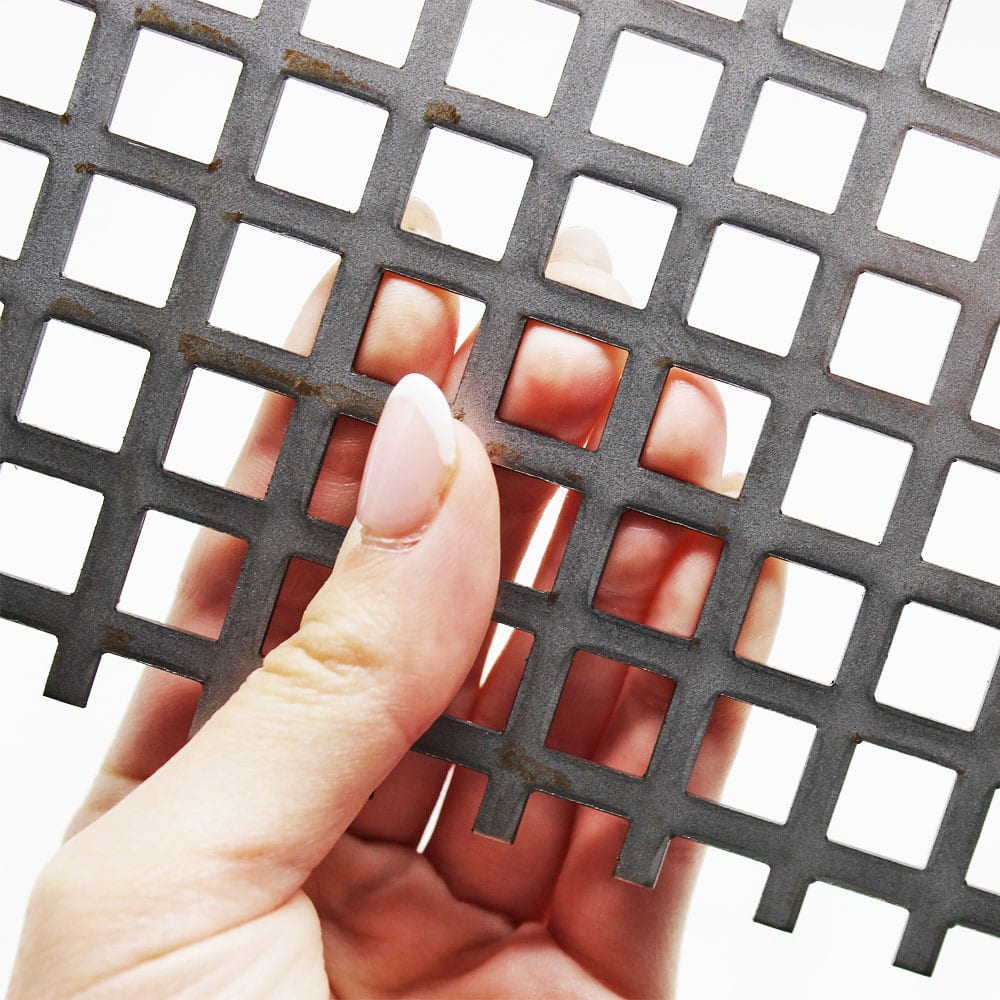

When it comes to versatile metal products, few options match the adaptability and strength of a square hole perforated sheet. Whether for architectural design, industrial applications, or custom fabrication, square hole perforated sheets offer a perfect blend of style and functionality. At Speciality Metals, we proudly stock a variety of square hole perforated sheet options, ready for UK-wide delivery.

In this comprehensive guide, we will explore everything you need to know about perforated sheet: its structure, benefits, uses, and how to choose the right type for your project.

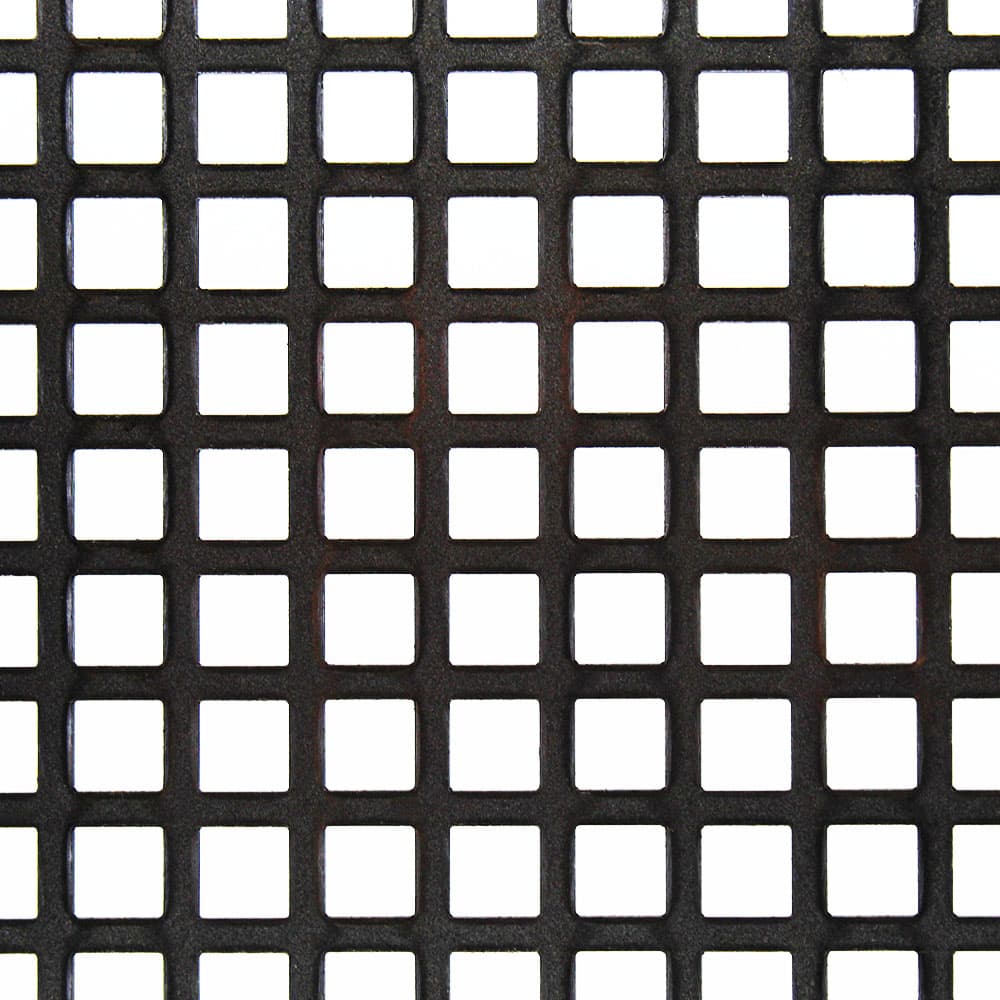

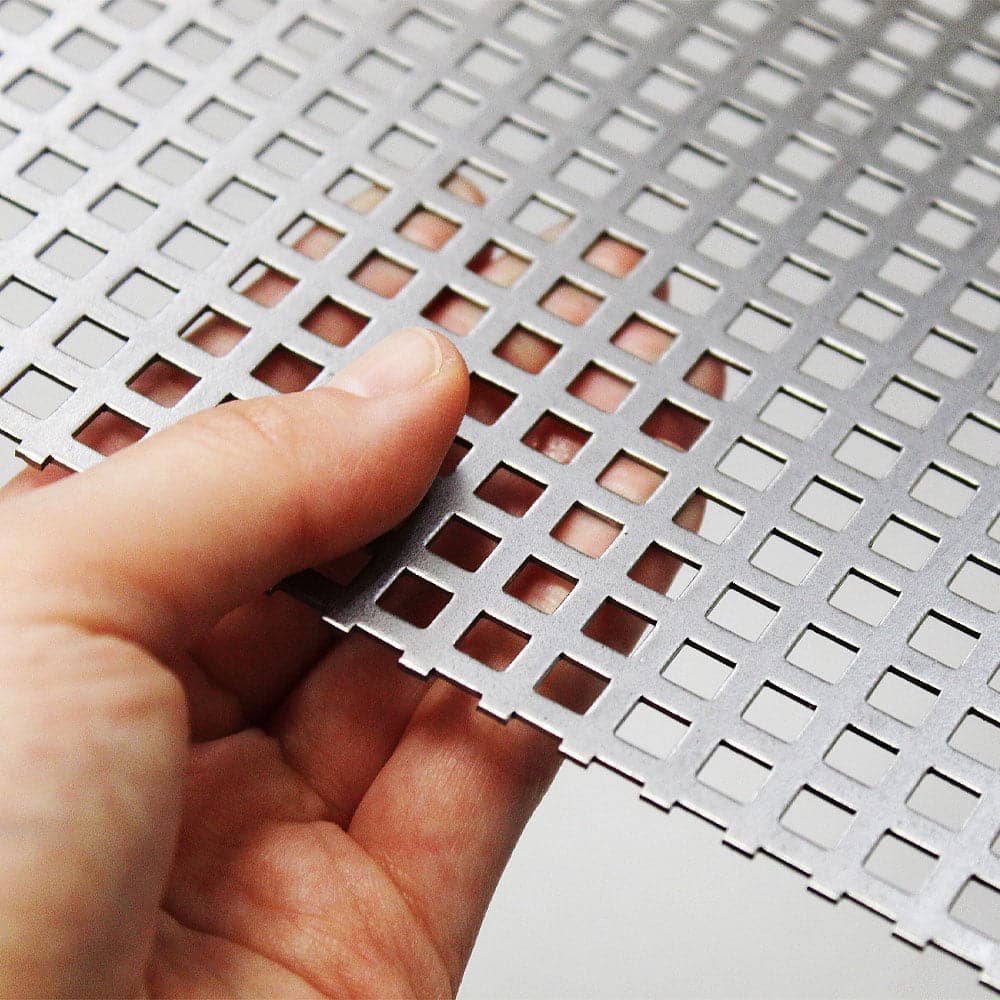

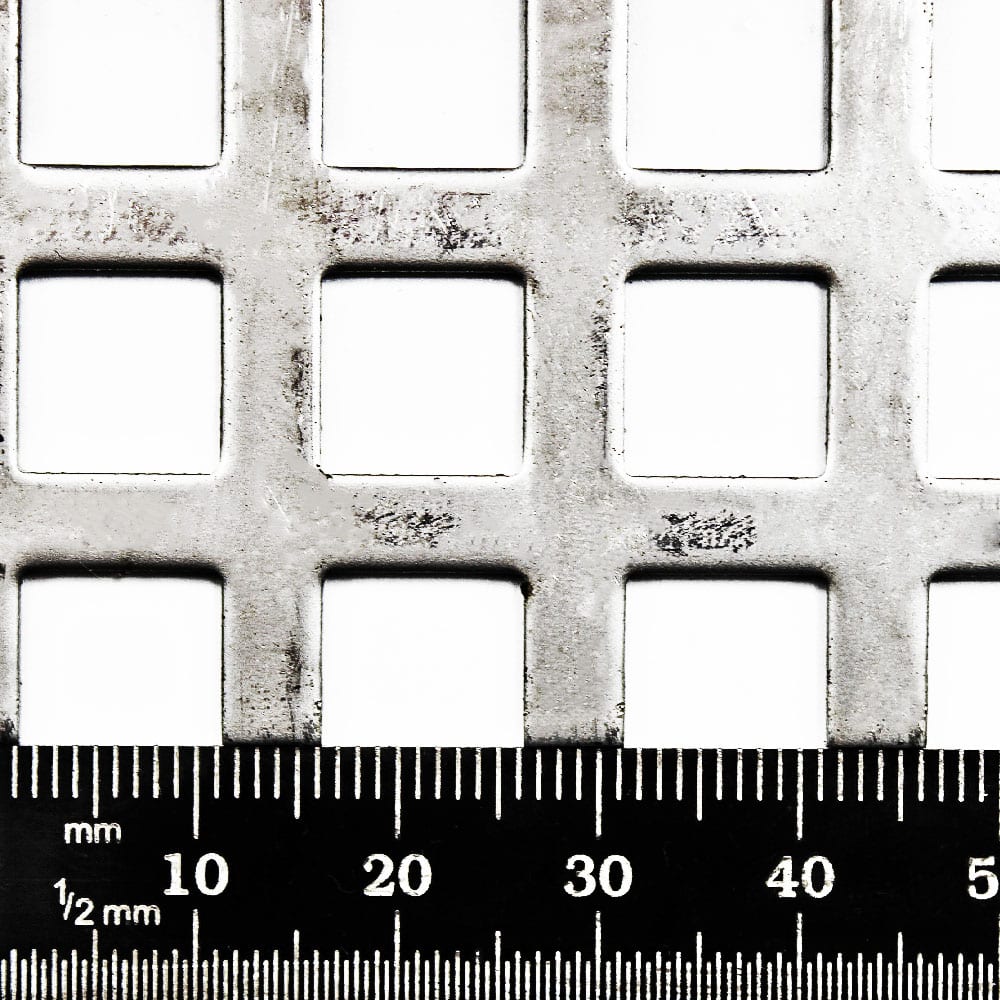

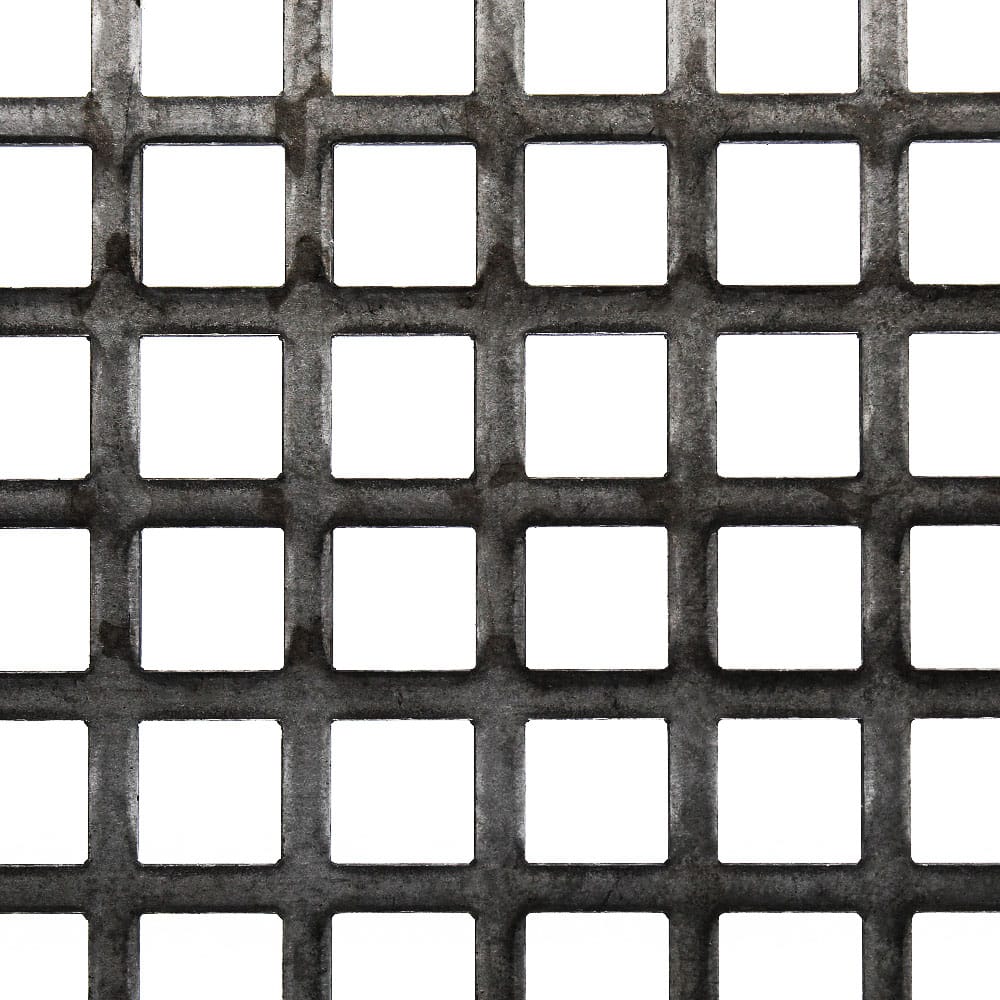

A square hole perforated sheet is a metal sheet that has been punched with a pattern of uniformly spaced square holes. These holes can vary in size and spacing, offering a range of options depending on airflow, strength, or aesthetic requirements.

Common materials used include:

At Speciality Metals, we supply perforated sheet in different materials and hole sizes to suit diverse applications.

Choosing a square hole perforated sheet brings several unique advantages:

Superior Strength: The square hole design maintains structural integrity while reducing weight.

Optimised Ventilation: Ideal for applications requiring good airflow.

Clean Aesthetic: Square holes offer a sharp, modern look.

Versatile Fabrication: Easy to cut, weld, and shape.

Lightweight Options Available: Particularly with aluminium sheets.

Thus, it is no surprise that perforated sheet is favoured across multiple industries.

Square hole perforated sheets are widely used across various sectors:

✔ Architectural Cladding

✔ Security Panels and Fencing

✔ Machine Guards

✔ Airflow Panels and Ventilation Covers

✔ Retail Fixtures and Shelving

✔ Ceiling Tiles and Decorative Partitions

✔ Acoustic Panels

✔ Furniture Designs and Custom Fabrication

Thanks to its open area and strength-to-weight ratio, perforated sheet is ideal where both strength and permeability are important.

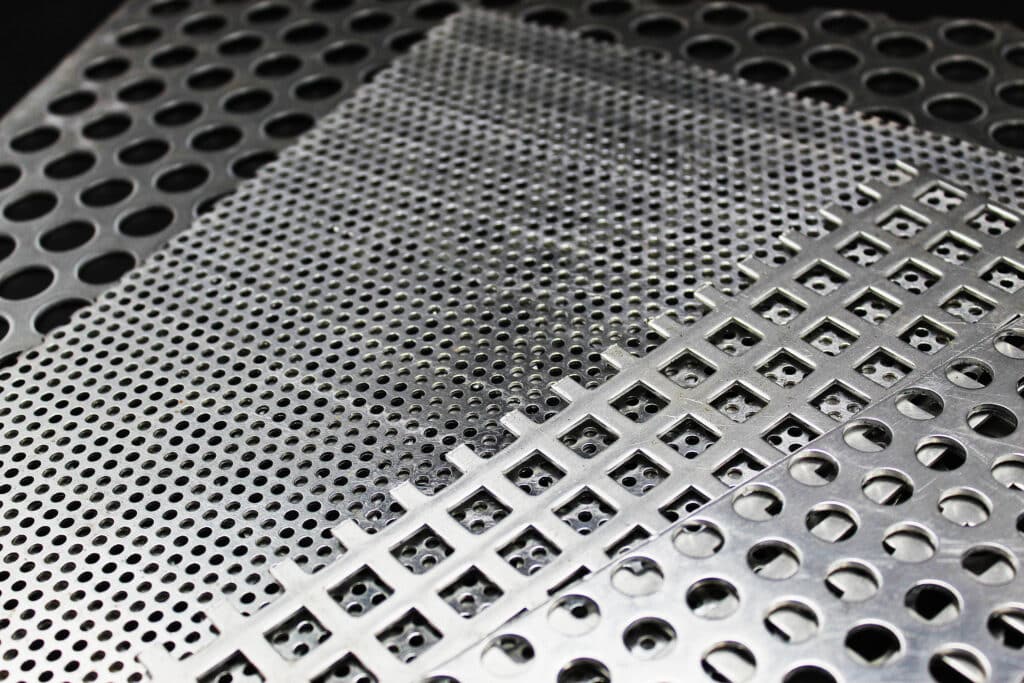

Here’s a quick comparison of materials often used for square hole perforated sheet:

| Material | Key Benefit | Common Applications |

|---|---|---|

| Mild Steel | Cost-effective and strong | Security grilles, industrial use |

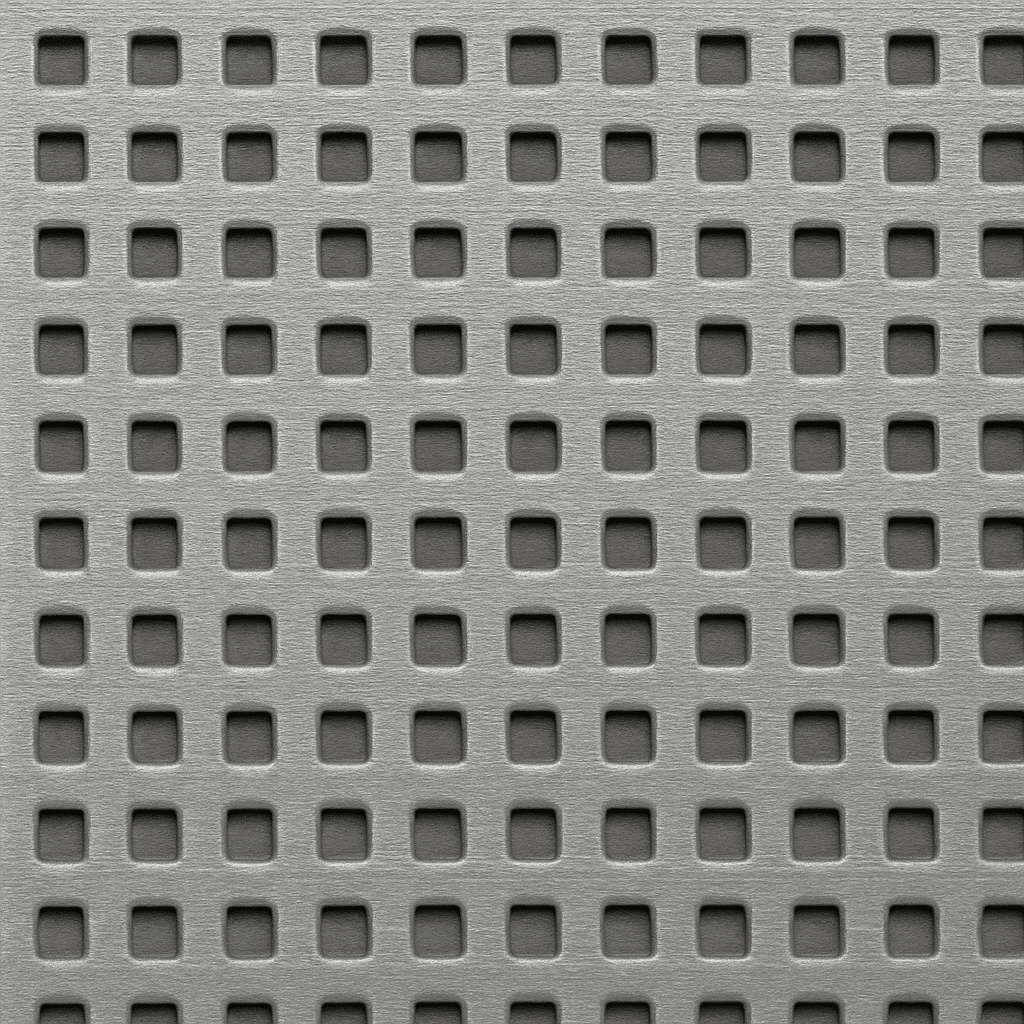

| Stainless Steel | Corrosion-resistant | Hygienic applications, outdoor installations |

| Aluminium | Lightweight and rust-proof | Architectural cladding, interior design |

✅ Tip: At Speciality Metals, you can find all three material types in various hole sizes and sheet thicknesses.

Before selecting your perforated sheet, consider:

Hole Size: Larger holes allow better airflow but reduce strength.

Open Area %: Affects airflow and weight.

Sheet Thickness: Thicker sheets provide more durability.

Material: Choose based on your environmental needs.

Finish: Options like powder coating or anodising for extra protection.

Selecting the right combination ensures maximum performance and longevity for your project.

At Speciality Metals, we stock a range of popular square hole perforated sheets, including:

✔ Extensive Range of Materials and Sizes

✔ Fast, Reliable UK Delivery

✔ High-Quality Standards and Finishing

✔ Custom Cut-to-Size Options Available

Whether you need a small panel or a bulk order, we have the capability to meet your needs.

Many customers ask whether they should opt for square or round hole perforated sheets. Here’s a brief overview:

Square Holes: Provide higher open area percentages and a cleaner, geometric look.

Round Holes: Slightly stronger in impact resistance and often used where decorative style is less important.

For most architectural and airflow applications, square hole perforated sheet is the preferred choice.

✔ Always use fine-tooth blades when cutting to avoid rough edges.

✔ Protect edges with a trim or beading if exposed to high traffic.

✔ Pre-plan weld points carefully to maintain strength and finish.

✔ For mild steel types, apply a rust inhibitor after cutting.

Following these practices ensures a professional finish and long-term performance.

Architects often use perforated sheet for stylish facades, sunshades, and building ventilation panels. Aluminium options are particularly popular for these uses due to their corrosion resistance and lightweight structure.

Machine guards, air diffusers, and HVAC equipment frequently incorporate perforated sheet because it combines airflow with durability.

Shelving units, hanging displays, and wall features in retail spaces rely on perforated sheet for its lightweight nature and strength.

Proper care ensures that your perforated sheet remains functional and attractive over time:

Mild Steel: Regular painting or coating prevents rust.

Stainless Steel: Occasional cleaning with mild detergent maintains the finish.

Aluminium: Requires minimal maintenance but benefits from anodised finishes for enhanced protection.

By applying appropriate treatments, you extend the life and maintain the look of your sheet.

As industries push towards combining functionality with aesthetics, perforated sheet is gaining popularity in:

Sustainable architecture (solar screens and green walls)

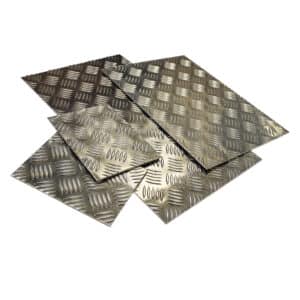

Lightweight transport applications (trailer floors, bus interiors)

Interior design innovations (metal art, partitions)

Hence, it’s a smart choice for future-proofing your projects.

A square hole perforated sheet is one of the most adaptable materials available today, offering strength, style, and functionality. Whether you’re building a protective screen, designing a decorative feature, or creating a ventilation panel, Speciality Metals has the ideal solution.

We proudly stock a comprehensive range of perforated sheets at competitive prices, with fast delivery available throughout the UK. Explore our website www.smetals.co.uk to view our full range and find the perfect product for your project.

Ready to get started?

Order your high-quality square hole perforated sheet from Speciality Metals today!

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options