- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Flat Bar vs Box Section: Which Is Right for You?

When it comes to metal profiles, two popular options stand out: flat bar and box section. Each has its own strengths and ideal applications, and selecting the right one can have a significant impact on the success of your build—whether it’s structural, decorative, or functional. At Speciality Metals, we offer a broad range of both profiles, and this guide will help you understand when and why to use each.

Flat bar, also known as flat stock, is a simple rectangular section of metal with a flat surface. It is available in a variety of thicknesses and widths, and it’s typically made from materials such as:

This makes it incredibly versatile for a wide array of applications. It can be cut, drilled, and welded with ease, making it a staple in fabrication and DIY projects alike.

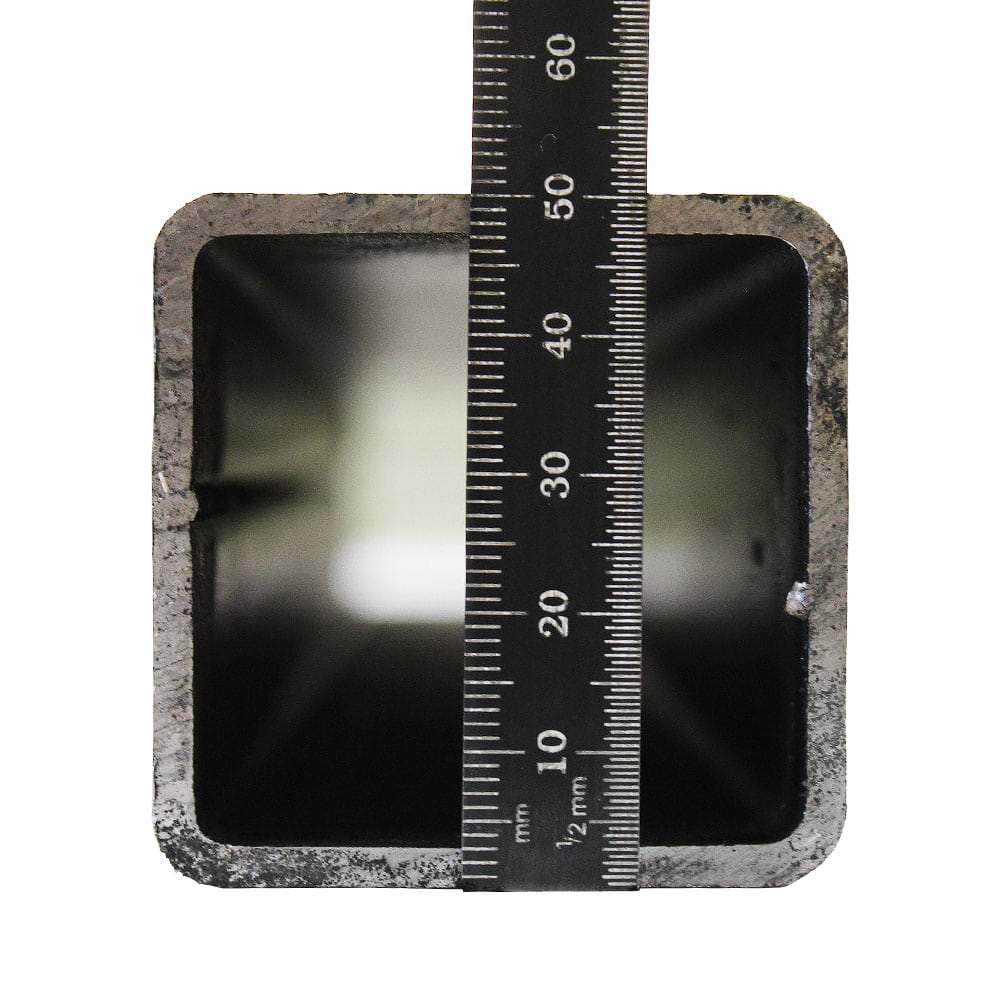

Box section (also referred to as hollow section or rectangular hollow section) is a tubular structure with square or rectangular cross-sections. It is often made from:

Aluminium

Box section provides a clean, enclosed profile with consistent wall thicknesses, which offers enhanced strength-to-weight ratios. It is popular in both architectural and structural uses.

While both are metal profiles, they serve very different purposes. Here’s a comparison across some critical categories:

| Feature | Flat Bar | Box Section |

|---|---|---|

| Shape | Solid, flat rectangle | Hollow square or rectangle |

| Weight | Heavier for the same dimensions | Lighter due to hollow core |

| Structural Strength | Lower in bending applications | Higher torsional and bending strength |

| Ease of Workability | Easier to cut, weld and form | Slightly more difficult due to enclosed design |

| Cost | Generally cheaper per metre | Can be more expensive depending on gauge & size |

| Finish | Ideal for aesthetic trims and details | Clean, minimal look for modern constructions |

Flat bar is ideal when simplicity and surface area are essential. It’s widely used in:

Brackets and supports

Shelving frames

Repairs and reinforcements

Decorative trims

Agricultural equipment

Our Aluminium Flat Bar 6082-T6 is a popular choice for lightweight support frames in DIY furniture and shelving. Its corrosion resistance and clean finish make it ideal for indoor and outdoor use alike.

Box section is preferable in structural applications where rigidity is crucial. It’s commonly used in:

Structural frameworks

Gates and fences

Vehicle chassis

Construction supports

Greenhouses and metal sheds

The Mild Steel Square Box Section available at Speciality Metals is widely used in heavy-duty construction due to its excellent strength-to-weight ratio and weldability.

Aluminium Flat Bar: Lightweight, corrosion-resistant, perfect for indoor/outdoor furniture.

Mild Steel Flat Bar: Cost-effective, easy to weld, great for bracing and repairs.

Stainless Steel Flat Bar: Durable and corrosion-resistant, ideal for hygienic or marine environments.

Mild Steel Box Section: Excellent for heavy frameworks, can be painted or galvanised.

Aluminium Box Section: Lightweight alternative, ideal for mobile or lightweight structures.

Stainless Steel Box Section: Best for high-corrosion environments or architectural finishes.

Here’s a generalised graph comparing the bending strength and relative weight of flat bar vs box section across common materials:

| Profile | Bending Strength (Relative) | Relative Weight (Units) |

|---|---|---|

| Flat Bar – Aluminium | 60 | 30 |

| Flat Bar – Mild Steel | 150 | 70 |

| Box Section – Aluminium | 120 | 40 |

| Box Section – Mild Steel | 300 | 90 |

Flat bar tends to be easier to cut and weld because it’s a simple solid piece. Box section, on the other hand, may require more specialised tools and considerations when welding (especially sealing the ends or preventing warping).

Use clamps for straight cuts

Great for beginners

Easily drilled for bolts or screws

Use a chop saw for clean cuts

Plan welds to reduce heat distortion

Protect internal surfaces from rust (mild steel)

Generally, flat bar is less expensive per metre than box section of the same width. However, box section can provide more strength with less material—reducing the need for additional supports, which can offset initial costs in large builds.

💡 Tip: If you’re building a structure that needs to be strong but lightweight (such as a bike rack, garden structure or display stand), box section will likely offer better value in the long run.

It depends entirely on what you’re building.

Choose flat bar if you need:

Simple brackets or support strips

A clean look for decorative applications

Easy welding and cutting

Choose box section if you need:

A rigid frame or skeleton

Superior load-bearing strength

A streamlined, modern finish

Use aluminium box section for lightweight, rust-proof structures that can handle British weather. Combine it with wood or composite panels for a stylish look.

Mild steel flat bar is perfect for custom brackets in workshop settings or shelving supports.

Opt for mild steel box section to ensure durability and resistance to bending or torsion over time.

Wide range of both flat bar and box section profiles

All available in multiple materials and thicknesses

UK-wide delivery

Competitive pricing and custom cutting available

Whether you’re building a raised bed for your garden or fabricating a support structure for machinery, we’ve got you covered with high-quality metal at the right size and strength.

Both flat bar and box section are incredibly versatile metal profiles. The key is understanding the demands of your project and choosing the profile that best suits your requirements. At Speciality Metals, we stock a comprehensive range of both, ready to be delivered straight to your door.

Need help deciding which one to use? Get in touch with our team—we’re happy to help you find the ideal solution for your next build.

As always, thank you for checking out our blog. We hope that this helps you with your project.

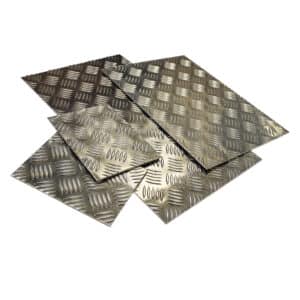

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options