- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Why Food-Grade Stainless Steel is Best for Kitchens & Industry

In both kitchens and industrial settings, choosing the right material for surfaces, equipment, and storage is essential. Food-grade stainless steel has become the industry standard due to its durability, corrosion resistance, and hygienic properties. Whether in commercial food production, catering, or pharmaceuticals, this metal plays a crucial role in maintaining safety and efficiency.

At Speciality Metals, we supply a range of stainless steel products, including sheets, perforated mesh, round tubes, and flat bars, all suited for food-related applications. This guide explores the benefits, applications, and maintenance of food-safe stainless steel, helping you select the right grade and product for your specific needs.

Stainless steel is an alloy of iron, chromium, nickel, and other elements, designed to resist corrosion. To qualify as food-grade, the material must meet stringent safety and hygiene standards, ensuring it does not leach harmful substances or react with acidic foods.

The two most widely used grades in kitchen and industrial applications are:

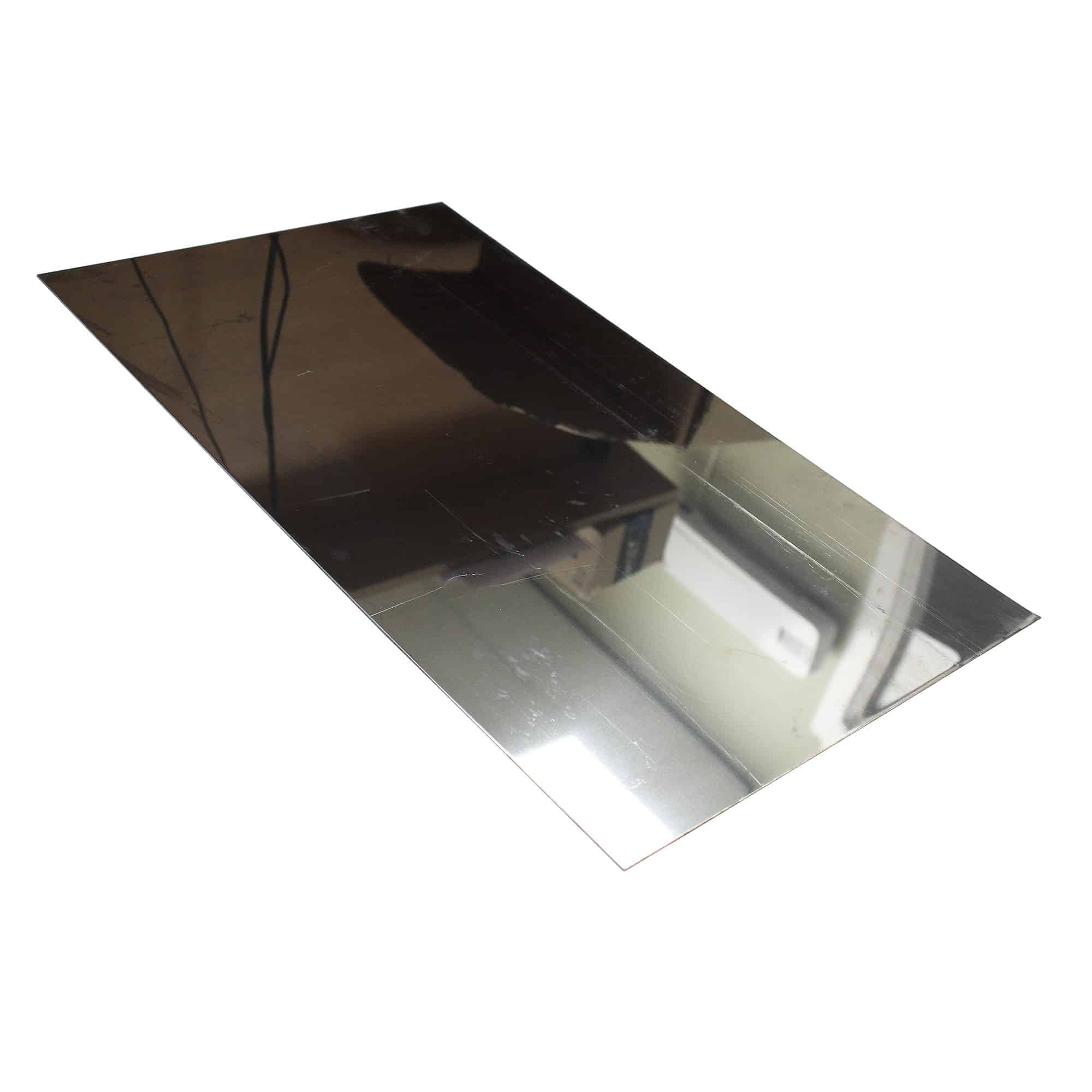

✔ 304 Stainless Steel – Highly resistant to corrosion, stains, and heat, making it ideal for sinks, worktops, and kitchen appliances.

✔ 316 Stainless Steel – Contains molybdenum, which enhances resistance to salts and chemicals, making it suitable for food processing and marine environments.

💡 Example from Speciality Metals: Our 304 Stainless Steel Sheet Metal is perfect for hygienic food prep surfaces in commercial kitchens.

💡 Example from Speciality Metals: Our 316 Stainless Steel Round Tube is ideal for dairy processing where exposure to acidic substances is common.

✔ Meets health standards – Essential for restaurants, hospitals, and food production facilities.

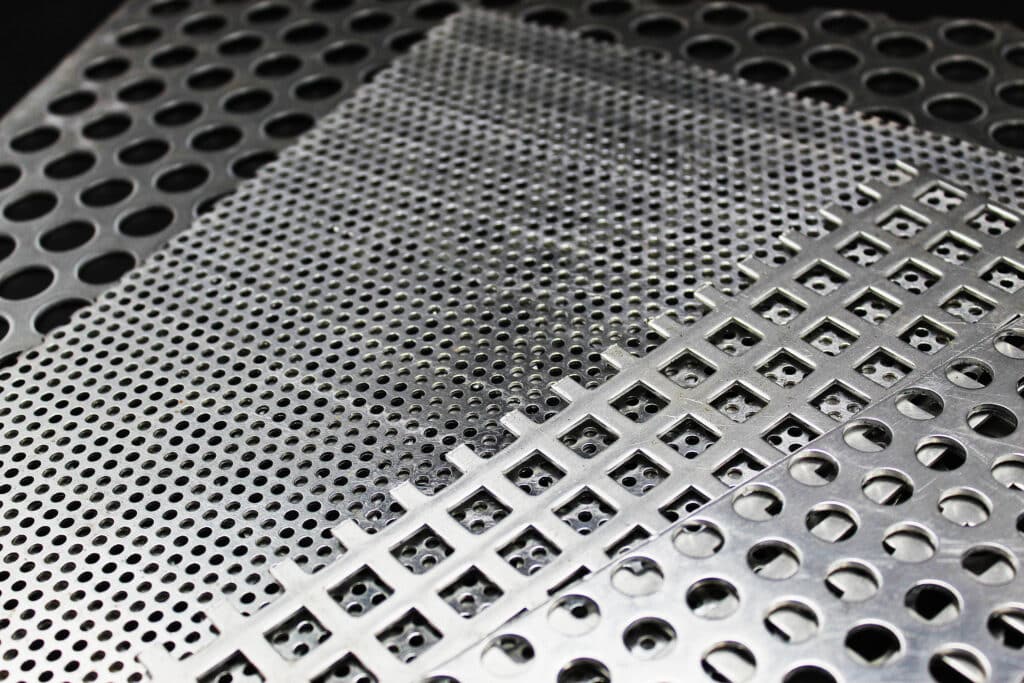

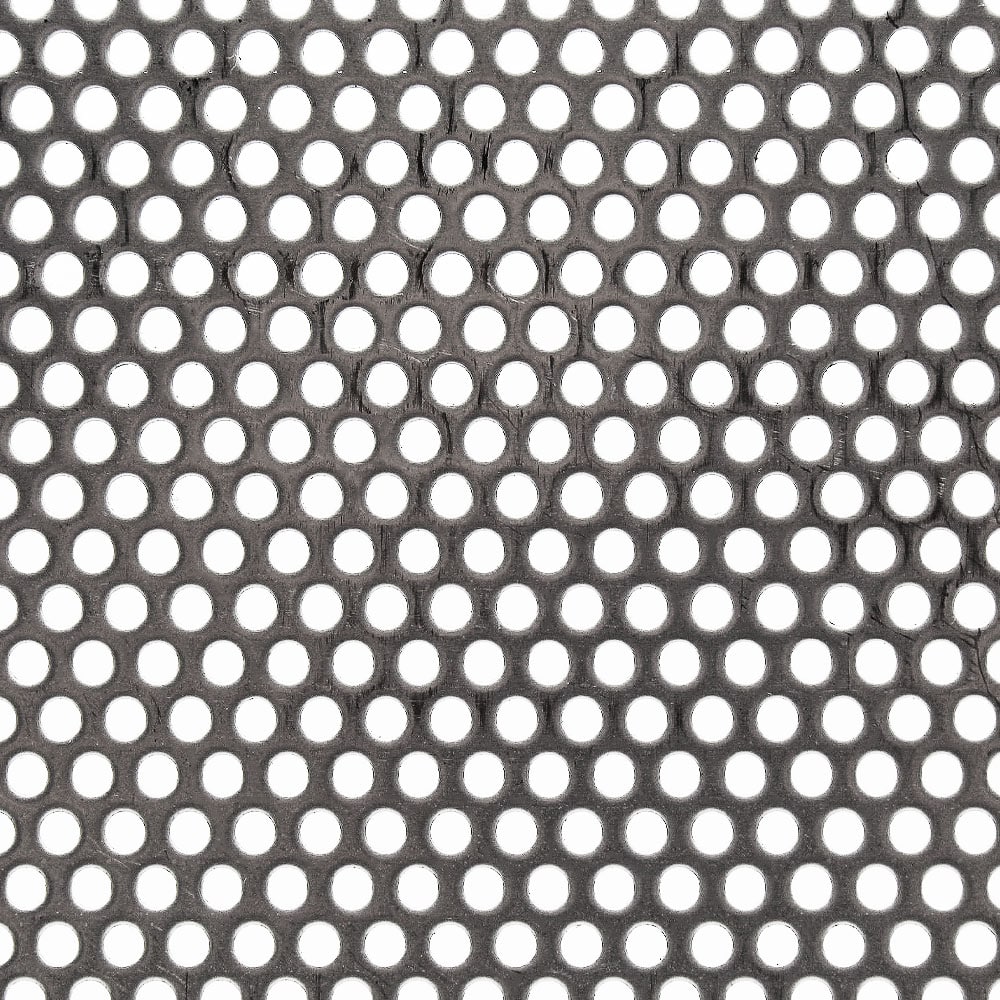

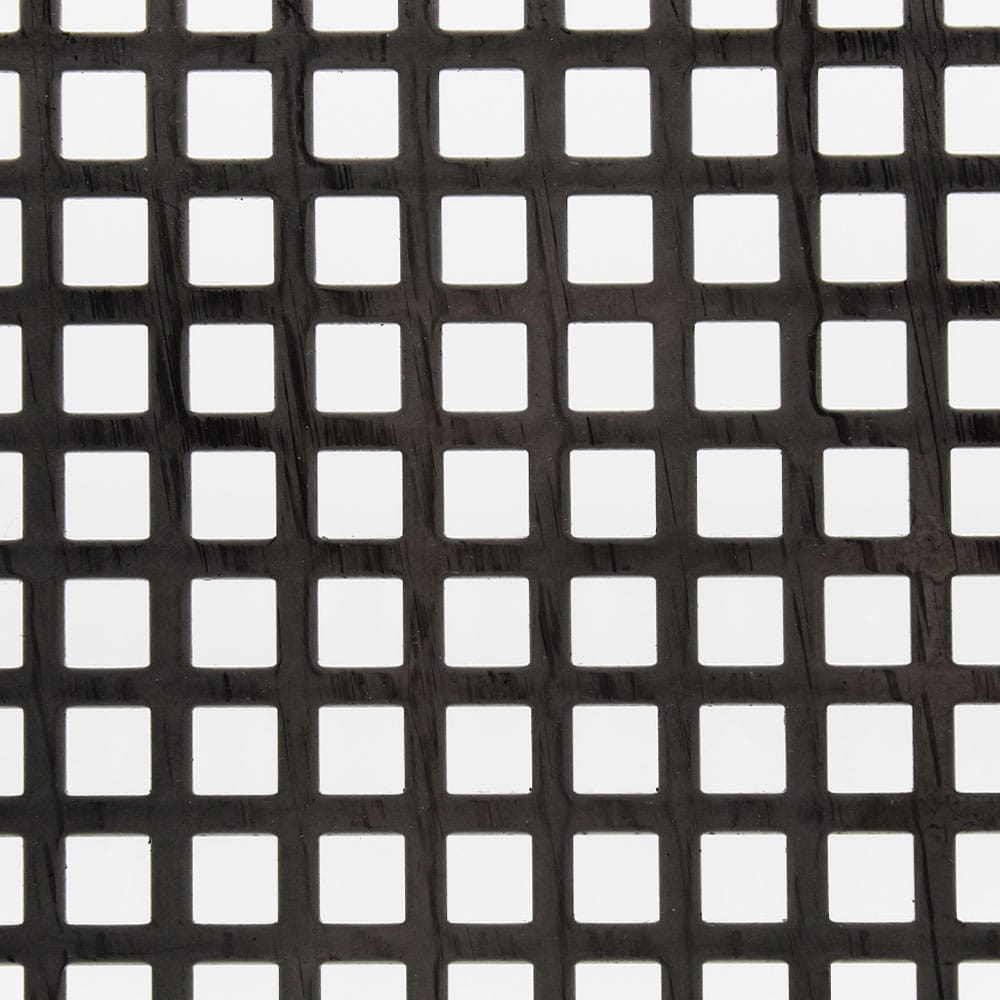

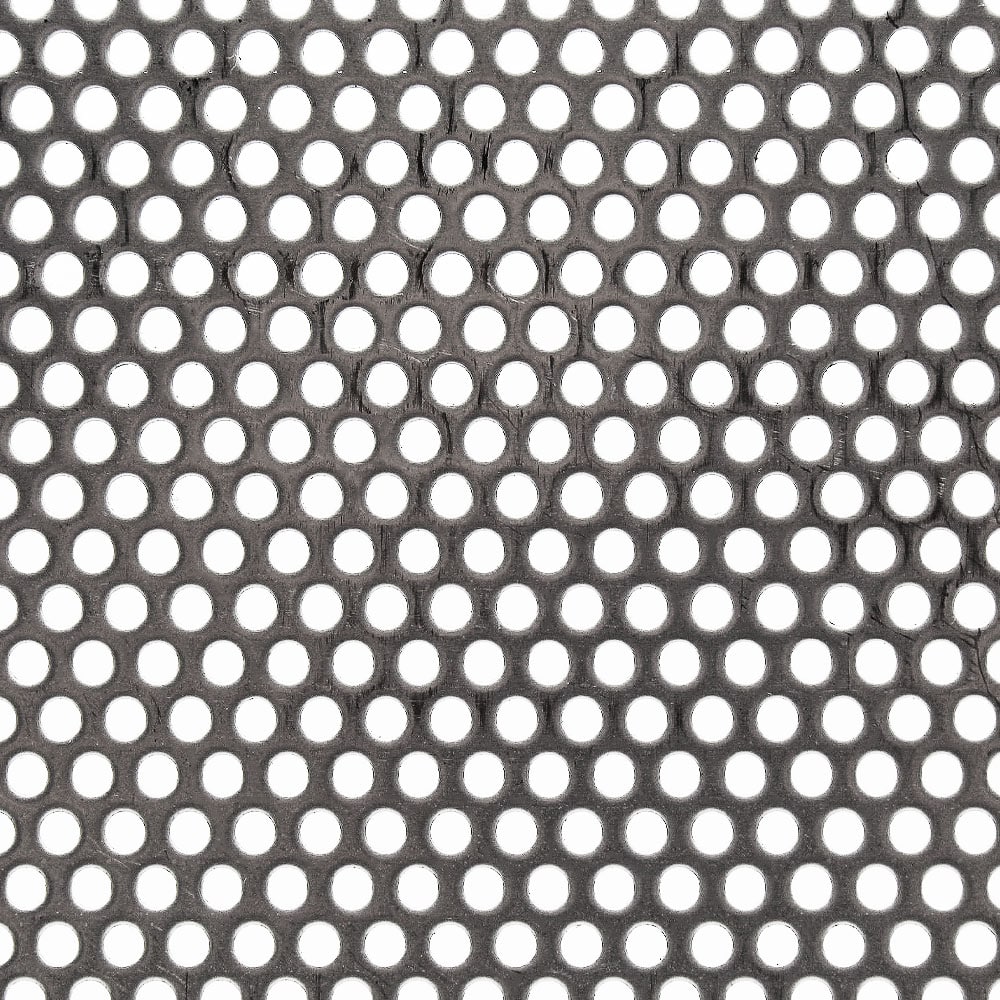

💡 Example from Speciality Metals: Our Stainless Steel Perforated Mesh is widely used in airflow and drainage systems, ensuring a sanitary environment.

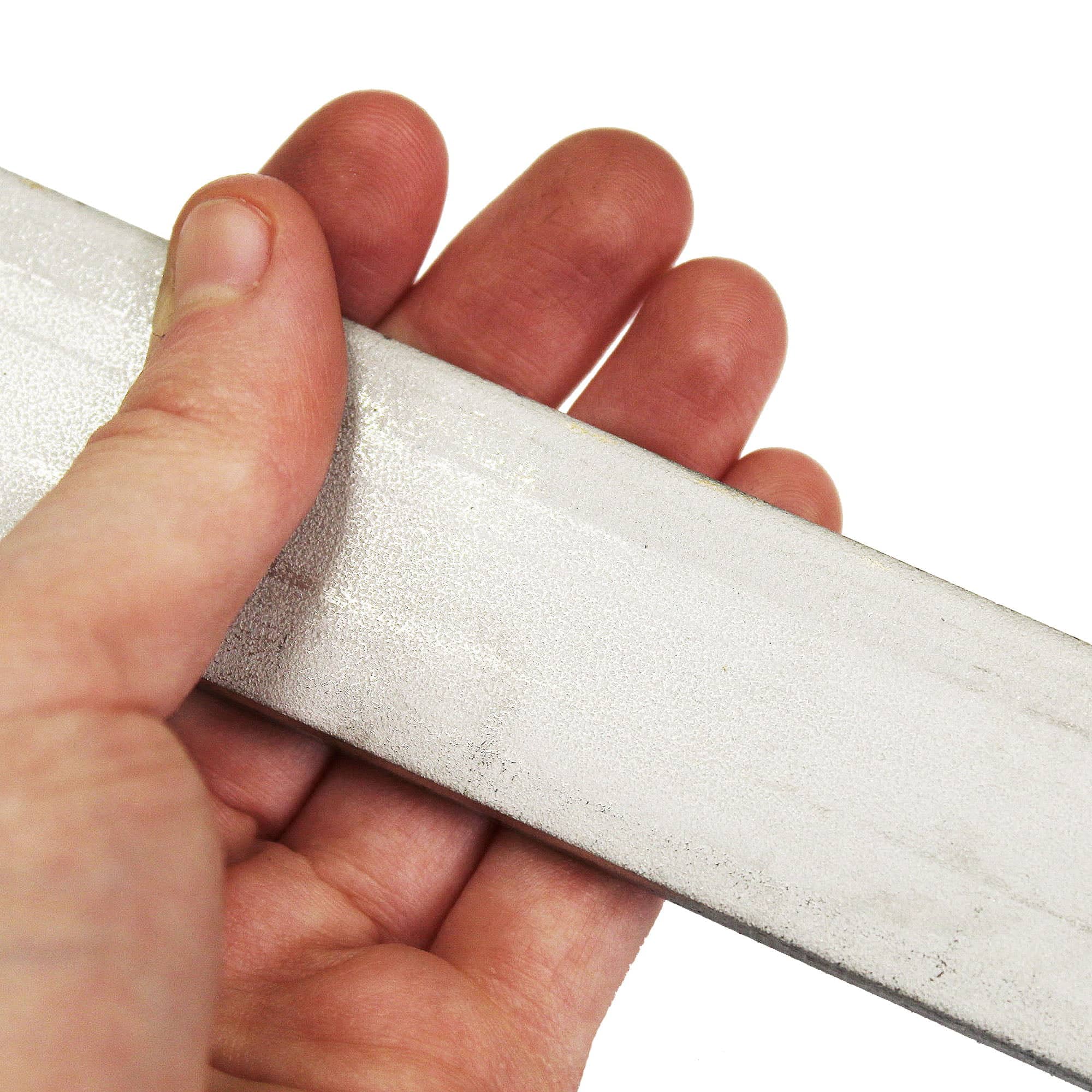

💡 Example from Speciality Metals: 304 Stainless Steel Flat Bars are used in kitchen splashbacks and shelving due to their toughness and easy maintenance.

✔ Enhances the look of restaurants, hotels, and industrial kitchens.

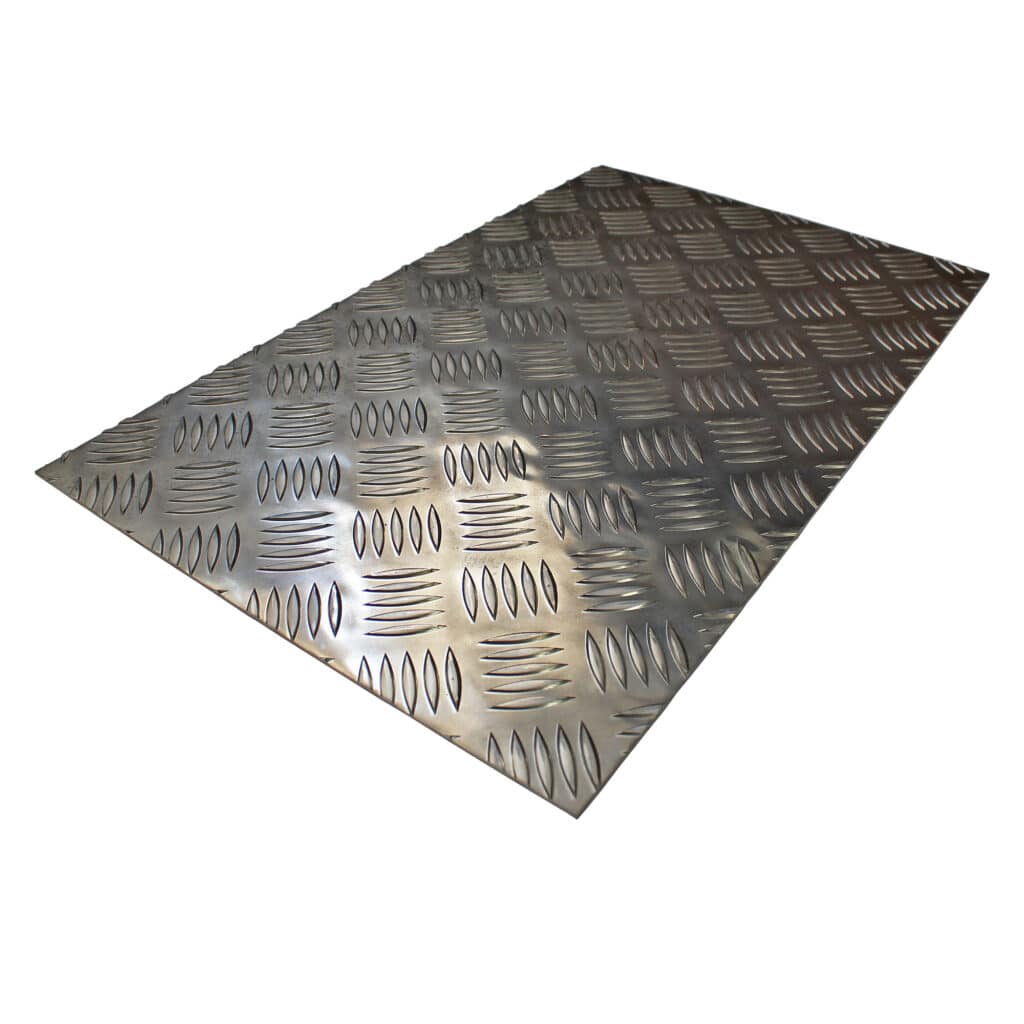

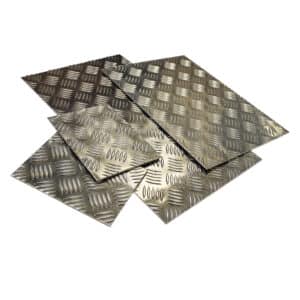

💡 Example from Speciality Metals: Stainless Steel Checker Plate adds a stylish yet slip-resistant surface for industrial workspaces.

💡 Example from Speciality Metals: Our Stainless Steel Box Sections are used in custom-built kitchen storage solutions.

💡 Example from Speciality Metals: 316 Stainless Steel Tubing is a top choice for breweries and juice production lines

💡 Example from Speciality Metals: Our Stainless Steel Round Tubes are widely used in brewing and distillation equipment.

Choosing the right stainless steel for food-related applications depends on several key factors:

🔹 Exposure to Chemicals: If the environment contains salts, acids, or harsh cleaning agents, 316 stainless steel is the best option due to its superior resistance.

🔹 Load-Bearing Requirements: For applications requiring structural strength, opt for thicker stainless steel sheets or tubes to ensure durability.

🔹 Heat Tolerance: Both 304 and 316 grades can withstand high temperatures, making them suitable for use in cooking, processing, and sterilisation equipment.

🔹 Hygiene Considerations: If ventilation or drainage is a concern, perforated or mesh stainless steel designs provide an efficient solution.

💡 Speciality Metals Recommendation: Our 304 Stainless Steel Perforated Mesh is widely used for industrial ventilation in food processing environments.

Proper maintenance ensures long-lasting performance and hygiene in food applications. Follow these best practices:

✔️ Clean Regularly: Use warm water and mild detergents to remove residues without damaging the surface.

✔️ Avoid Harsh Chemicals: Steer clear of chlorine-based cleaners, as they can weaken the protective chromium layer.

✔️ Enhance Shine: Applying a stainless steel polish maintains a sleek, professional finish and reduces fingerprint marks.

✔️ Dry Immediately: Wiping surfaces dry after cleaning prevents water spots and mineral deposits, keeping the material in prime condition.

💡 Speciality Metals Tip: For a spotless and hygienic look, apply stainless steel polish to kitchen worktops and appliances.

| Metal Type | Corrosion Resistance | Hygienic? | Strength | Common Uses |

|---|---|---|---|---|

| 304 Stainless Steel | High | Yes | Strong | Kitchen surfaces, appliances |

| 316 Stainless Steel | Very High | Yes | Stronger than 304 | Food processing, marine use |

| Aluminium | Medium | Yes | Lightweight | Cookware, trays |

| Copper | Medium | Antimicrobial | Softer metal | Brewing, decorative finishes |

✔ Stainless steel outperforms aluminium and copper in food safety and durability.

Food-grade stainless steel is the leading choice for commercial kitchens, food processing facilities, and industrial use. Its corrosion resistance, strength, and hygienic properties make it an essential material for food safety.

✔ Resists rust and stains – Long-lasting and low maintenance.

✔ Hygienic and easy to clean – Perfect for food contact surfaces.

✔ Durable under extreme conditions – Ideal for high-temperature applications.

✔ Aesthetic and professional – Enhances the look of modern kitchens.

At Speciality Metals, we offer a comprehensive range of food-grade stainless steel products, including sheets, tubes, and perforated mesh, designed for hygienic and industrial use.

💡 Looking for expert guidance? Visit www.smetals.co.uk to explore our stainless steel range or contact us for advice on choosing the right materials.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options