- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

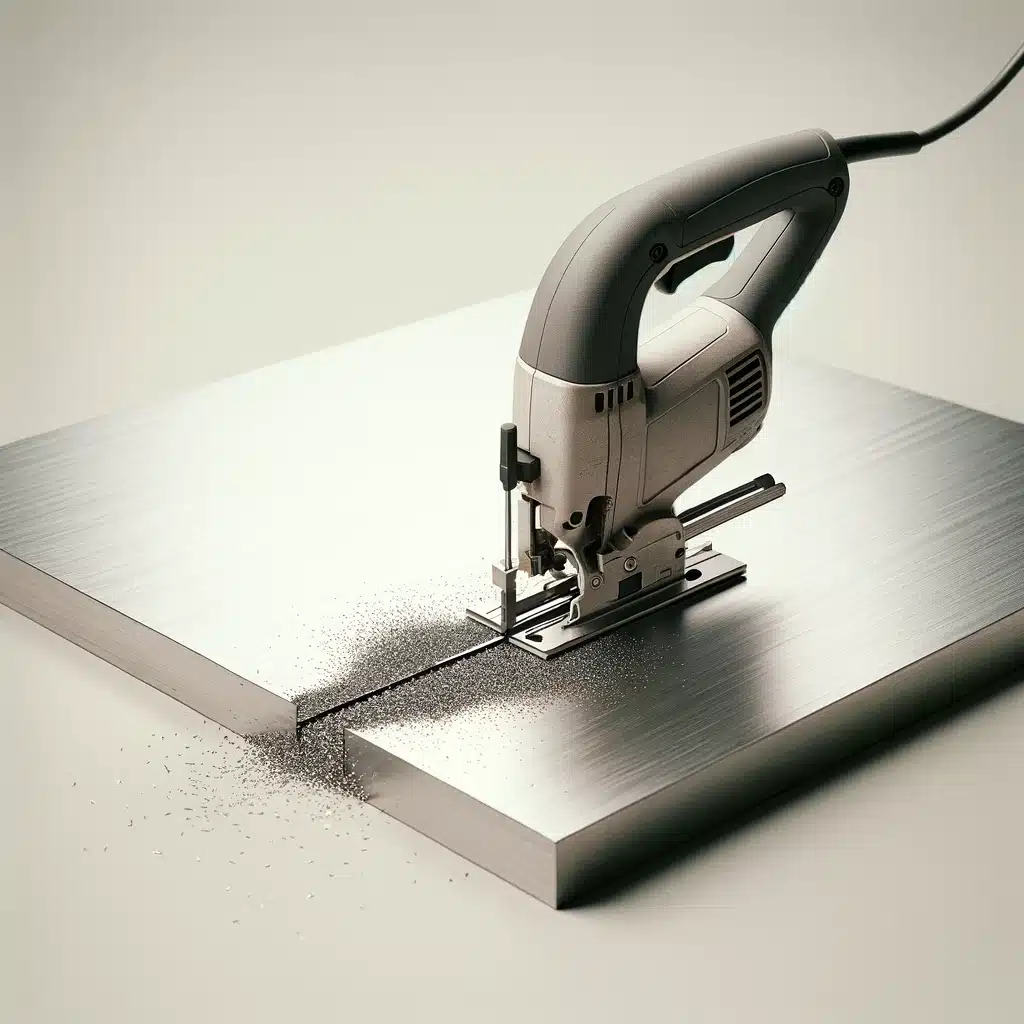

Home » The Ultimate Guide to Cutting Metal with a Jigsaw: Tips, Techniques, and Safety

The jigsaw, a versatile and powerful tool in the arsenal of metalworkers and DIY enthusiasts alike, stands out for its ability to cut through metal with precision and ease.

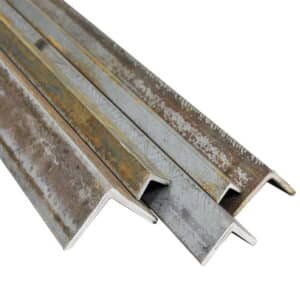

Capable of handling a variety of metals, including stainless steel, mild steel, and aluminium, the jigsaw offers unparalleled flexibility in cutting shapes, curves, and straight lines.

However, to harness this tool’s full potential, understanding the appropriate blades, settings, and cutting techniques is crucial. This guide aims to delve deep into the nuances of using a jigsaw for metal cutting tasks, covering everything from the basics of the tool itself to selecting the right blade for your project.

Whether you’re tackling a professional metalworking project or embarking on a DIY endeavor, the insights provided here will equip you with the knowledge to achieve clean, precise cuts, enhancing the quality of your work and expanding the scope of your projects.

We hope that the following article proves to be useful. Let’s go…

Jigsaws use reciprocating blades to cut through material by moving up and down. When paired with the right blade and settings, this simple yet effective mechanism is suitable for cutting metal. Various types of jigsaws are available – corded, which provides continuous power, cordless, which offers mobility and convenience, and variable speed, which allows you to control the speed according to the hardness of the material.

In selecting a jigsaw for metal cutting, consider factors such as power output, which affects the tool’s ability to cut thicker and harder metals, and stroke length and orbital action settings, which influence cut speed and efficiency. A jigsaw with adjustable orbital action, for instance, can be set to use an elliptical cutting motion to enhance metal cutting efficiency. By evaluating these aspects, you will be able to select a jigsaw that meets both your metal cutting needs and complements your overall toolkit.

Selecting the right blade is the key to successful metal cutting with a jigsaw. Metal cutting jigsaw blades are typically made from bi-metal or tungsten carbide and have a tooth design and density (measured in TPI – teeth per inch) optimised for metal. The higher the TPI count, the smoother the cuts, but at a slower speed, making it ideal for cutting thin metal sheets. Conversely, a lower TPI blade can cut thicker metals more quickly but with rougher edges.

For instance, a fine-toothed bi-metal blade is suitable for thin stainless steel sheets, while a coarser, tungsten carbide blade may be better for thick aluminum plates. To maintain optimal cutting performance, inspect your blades regularly and replace them when necessary. A dull blade can cause inaccurate cuts, increased workpiece damage, and safety risks. A properly maintained blade, coupled with the correct metal alloy and thickness, will ensure that your jigsaw cuts efficiently and effectively, improving the quality of your project.

Before diving into the cutting process, setting up your workspace correctly can significantly impact the precision and safety of your work. Here’s how to ensure your metal cutting project starts on the right foot:

Workspace Preparation: Work in a well-lit, well-ventilated area. Keep your workspace free of clutter and flammable materials. Cutting safely and accurately requires a stable work surface.

Clamping Your Metal: Clamp the metal piece firmly to your workbench. As a result, the metal does not shift during cutting and vibration is reduced. Ensure that all sides of larger pieces are adequately secured with multiple clamps.

Marking Cut Lines: Clearly mark the cut lines on your metal piece with a non-permanent marker or a scribing tool. To ensure accuracy, consider using a template for complex patterns or shapes. Straight lines can be achieved with the help of a straightedge or ruler.

Safety Gear: Before you begin cutting, make sure you are wearing the appropriate safety gear. Wear safety glasses to shield your eyes from metal filings, gloves to shield your hands, and ear protection to guard against noise. In confined spaces, consider wearing a dust mask.

Minimising Vibration: The metal piece should be as close to the workbench as possible in order to minimise vibration. It is also possible to reduce movement of the workpiece by using anti-vibration clamps or mats under it.

Cutting different metals with a jigsaw requires specific techniques to ensure clean cuts and to maintain the integrity of the metal:

Stainless Steel: It is recommended to use a bi-metal blade with a high TPI count when cutting stainless steel. Make sure you go slowly to prevent overheating, which can result in the blade wearing out more quickly as a result. By lubricating the blade with cutting oil, you are able to reduce friction and improve the quality of your cut.

Mild Steel: It is easier to cut mild steel than stainless steel. Cutting with a medium TPI blade allows for a balance between speed and smoothness. Start the cut with a small pilot hole if the steel is painted or coated.

Aluminium: Since aluminium is softer than steel, it can clog blades designed for harder metals. For easier chip removal, use a blade with a lower TPI. The blade’s heat should be applied at a steady, moderate speed to avoid melting the aluminium.

Cutting Curves and Intricate Patterns: Choose a blade with a narrower profile for curves and intricate patterns. Initially, cut slowly to establish the path, then increase speed gradually while maintaining control and following your guide lines.

Creative Project Ideas: Jigsaws are versatile tools that can be used for a variety of tasks. You can create custom metal artwork, decorative panels, or even furniture accents. When practiced, you can use a jigsaw to make detailed cuts for garden sculptures, bespoke home décor, or automotive modifications.

Using the right cutting techniques and understanding the specific needs of each metal will allow you to achieve professional-grade results with your jigsaw.

Even with the best preparation and equipment, you may encounter issues when cutting metal with a jigsaw. Here are some common problems and their solutions:

Blade Wandering: Using the wrong type of blade or applying uneven pressure may cause your blade to deviate from the cut line. Keep a steady hand and use a blade with the appropriate TPI for your metal’s thickness. Keeping your material firmly clamped can also prevent shifting, which can cause the blade to wander.

Rough Edges: Rough edges are often caused by low TPI blades or moving the jigsaw too quickly through the material. To achieve smoother edges, choose a blade with a higher TPI and slow your cutting speed. When cutting metal, patience is key.

Overheating: When you cut metal, you generate heat, which can dull your blade and affect the quality of the cut. For this reason, periodically pause to let the blade cool down, and apply a cutting lubricant to reduce friction and heat buildup.

Adjusting Technique and Settings: Reassess your jigsaw’s speed settings if issues persist. It is easier to control a variable speed jigsaw, especially when cutting different types of metal. By adjusting the speed based on the metal’s hardness, cleaner cuts can be achieved and blade wear can be reduced.

After-Cut Finishing: A professional finish depends on deburring and smoothing the edges after your cut. You can use a file, sandpaper, or a deburring tool to remove any sharp burrs or roughness along the cut edge. A fine-grit sandpaper or specialised metal polish can be used to polish the metal.

The maximum thickness of metal sheet that can be cut by a jigsaw largely depends on the type of metal, the blade used, and the power of the jigsaw itself. Generally, a jigsaw can handle:

To ensure a clean cut and to prevent damage to the tool or the workpiece, it’s crucial to select the right blade for the metal type and thickness. For your specific equipment, refer to the manufacturer’s recommendations and blade specifications.

As we’ve explored throughout this guide, jigsaws offer versatility and precision when cutting metal. By understanding the importance of selecting the right blade, adjusting cutting techniques, and addressing common issues, you can significantly enhance your metalworking skills. Whether you’re a professional fabricator or a DIY enthusiast, mastering the use of a jigsaw in metal cutting opens up a world of creative and practical possibilities.

We encourage you to explore the extensive range of metals suitable for cutting at Speciality Metals. With our commitment to providing high-quality materials and expert advice, we’re here to support your projects from conception to completion.

Remember, the key to success in metalworking lies in combining the right tools with knowledge and creativity. Happy cutting!

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options