- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Strength Unveiled: Comparing Aluminium, Mild Steel, and Stainless Steel Across Key Profiles

In the realm of metalworking and construction, the strength of materials is a paramount consideration.

It impacts everything from structural integrity to design versatility and cost-effectiveness. Three materials stand out for their widespread use and unique properties: aluminium, mild steel, and stainless steel. The strengths and weaknesses of each of these materials make them suitable for various applications across different industries.

A comprehensive guide to the strength of these metals explores their performance in various forms, including sheet metal, round tubes, box sections, angles, and flat bars. We will compare the tensile strength, durability, and real-world applications of aluminium, mild steel, and stainless steel.

Our article will explore the nuances of metal strength, guiding you through the pros and cons of each material in different contexts, from the lightweight versatility of aluminium to the robust durability of mild steel. Knowing the strengths of these materials will empower you to make informed decisions for your projects, regardless of whether you’re an engineer, designer, or DIY enthusiast.

Let’s go…

When it comes to sheet metal, the choice between aluminium, mild steel, and stainless steel is often determined by tensile strength and durability requirements. Among industries requiring weight reduction, such as automotive and aerospace, aluminium sheet metal is popular because of its lightweight and corrosion resistance. Due to its ease of fabrication, it is ideal for intricate designs, though it has a lower tensile strength than steel.

In contrast, mild steel sheet metal is celebrated for its exceptional strength and flexibility. In structural applications where load-bearing capacity is crucial, it is a go-to material. Its affordability and weldability also make it a preferred choice in construction and industrial fabrication. In the absence of proper treatment or coating, mild steel is susceptible to corrosion.

Stainless steel sheet metal combines strength and corrosion resistance. It is an ideal choice for environments that require both durability and aesthetic appeal, such as architectural and kitchen environments. The trade-off, however, comes in the form of a higher cost and a more challenging fabrication process compared to mild steel.

Aluminium Sheet Metal:

Mild Steel Sheet Metal:

Stainless Steel Sheet Metal:

Aluminium, mild steel, and stainless steel round tubes each have their own distinct advantages, influenced by their strength and structural integrity. The lightness of aluminum tubes makes them ideal for bicycle frames and portable structures. While they may not withstand the same level of stress as steel tubes, their weight-to-strength ratio is advantageous.

Construction and automotive industries commonly use mild steel tubes for their robustness. Due to their strength and weight, they are suitable for frames, roll cages, and structural supports. Their versatility in welding and fabrication is a significant plus, though like sheet metal, they require protective measures against corrosion.

Due to their strength and corrosion resistance, stainless steel tubes are a preferred choice for architectural designs and applications that require both strength and durability. Decorative installations, handrails, and modern building structures commonly use them. Although stainless steel tubes are more expensive and require specialised welding, their strength makes them suitable for high-stress environments.

Each of these materials has unique properties that determine its suitability for various applications. Selecting the right material for the job requires understanding these characteristics in order to ensure both efficiency and durability.

Aluminium Tubes:

Mild Steel Tubes:

Stainless Steel Tubes:

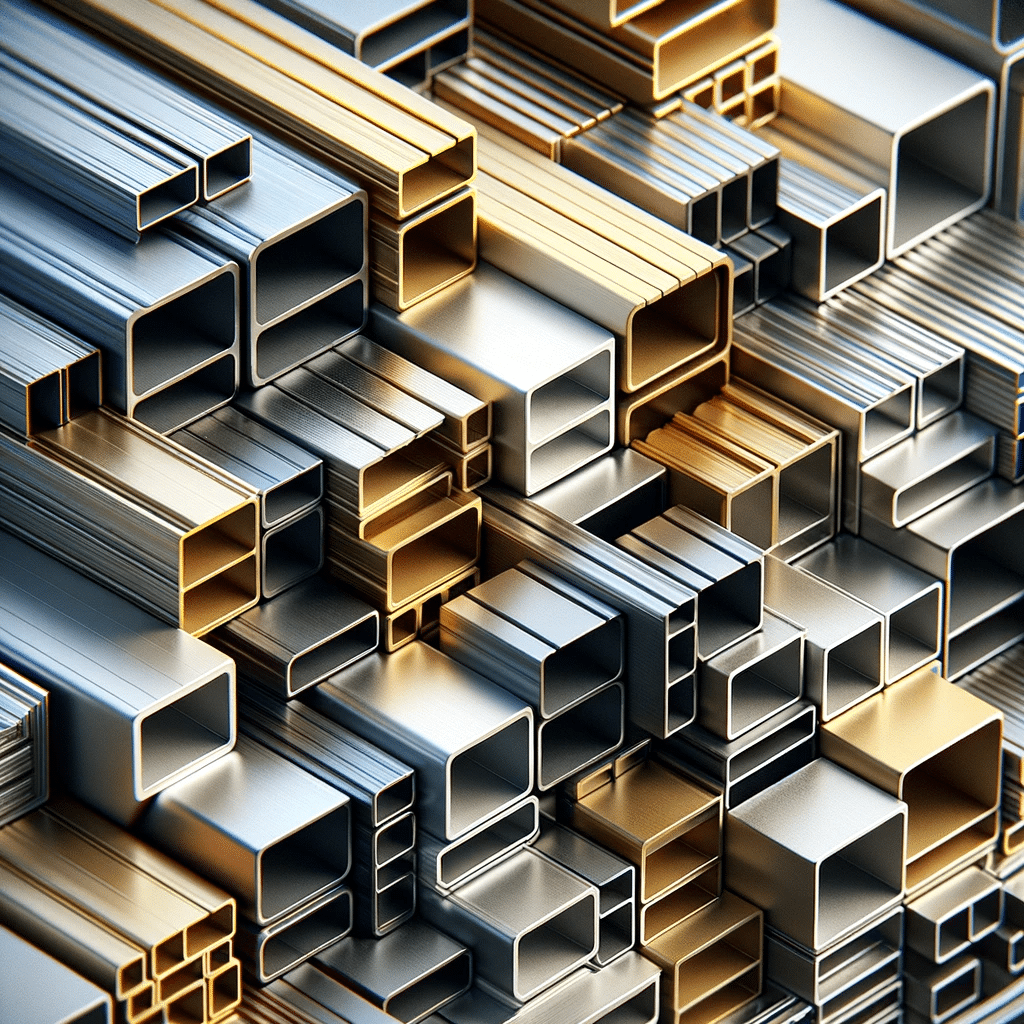

Comparing aluminium, mild steel, and stainless steel for box section profiles is a study in balancing load-bearing capacity, rigidity, and practicality. Aluminium box sections are highly valued for their light weight, which makes them ideal for applications that require a reduction in overall load. However, they are generally less suitable for heavy structural applications due to their lower load-bearing capacities. Aluminium is easier to work with when it comes to fabrication, offering a blend of flexibility and ease that appeals to a variety of design aesthetics, especially where a modern, clean appearance is desired.

Box sections made of mild steel are remarkable for their load-bearing capacity and rigidity. Their structural integrity makes them indispensable in heavy-duty manufacturing and construction. Though they are more challenging to work with than aluminium, their strength-to-cost ratio is highly advantageous. For longevity, especially in harsh environments, prevention treatments are necessary due to their vulnerability to corrosion.

Stainless steel box sections combine strength and corrosion resistance. Aesthetics and functionality are especially important in architectural applications. In spite of its higher cost, stainless steel provides excellent rigidity and load-bearing capabilities. Corrosion resistance and minimal maintenance requirements make it a long-term, cost-effective solution in environments exposed to elements or corrosive substances.

Aluminium, mild steel, and stainless steel angle profiles serve distinct purposes based on their strength characteristics. Lightweight framing and applications requiring ease of installation are ideal for aluminium angles. Due to their resistance to bending under lower loads, they are often used in decorative frameworks or non-structural components.

Most structural applications require mild steel angles. Due to their high resistance to bending and torsional forces, they are ideal for heavy frames, brackets, and supports that require a substantial load-bearing capacity. The ease of welding mild steel further enhances its suitability for complex structural applications, though its susceptibility to rust requires protective coatings in outdoor or humid environments.

Angle profiles made of stainless steel combine strength with aesthetic appeal. Modern architecture, commercial kitchens, and medical facilities often use them in visible structural elements to ensure a clean, rust-free appearance. In environments where corrosion resistance and minimal maintenance are priorities, stainless steel angles excel.

Aluminium Angle Profiles:

Mild Steel Angle Profiles:

Stainless Steel Angle Profiles:

Flat bars made from aluminium, mild steel, and stainless steel have different tensile strengths and flexibility. The inherent lightness and malleability of aluminum flat bars make them ideal for applications that require moderate strength but are concerned about weight. The materials are commonly used for decorative trims, lightweight frames, and supports where aesthetics are as important as functionality.

Known for their high tensile strength and flexibility, mild steel flat bars are a workhorse in the metal industry. A wide range of load-bearing applications include building supports, machinery parts, and vehicle frames. In spite of the fact that mild steel is relatively inexpensive, it is an attractive option for a wide range of applications, although it requires protective treatments against environmental wear.

In harsh environments, stainless steel flat bars are ideal because of their strength and corrosion resistance. Architecture details, modern furniture designs, and fixtures in high-moisture areas benefit from their aesthetic appeal and maintenance-free nature. In industries such as food processing, medical equipment, and marine applications, where longevity and cleanliness are important, stainless steel flat bars are a preferred choice.

Aluminium Flat Bars:

Mild Steel Flat Bars:

Stainless Steel Flat Bars:

We’ve explored aluminum, mild steel, and stainless steel in various forms like sheet metal, round tubes, box sections, angle profiles, and flat bars and uncovered a tapestry of strengths and applications. Aluminium shines in applications where weight reduction is important because of its light weight and corrosion resistance. Heavy-duty structural applications rely on mild steel because of its tensile strength and cost-effectiveness. Strength and corrosion resistance combine to make stainless steel the material of choice in environments that demand durability and aesthetics.

This comparative study shows how important it is to pick the right material based on your project’s requirements. In this decision-making process, budget constraints, environmental conditions, and the intended use of the material all play a role. By understanding the unique properties and strengths of each material, you can make smarter, more efficient design and construction decisions.

Let this guide serve as a compass as you navigate the world of metal materials for your next project, whether it’s construction, manufacturing, or design. When you know this, you can make informed choices that optimise performance and cost, ensuring your success and longevity.

| Material | Form | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Density (g/cm³) |

| Aluminium | Sheet Metal | 110-310 | 30-280 | 1-40 | 2.7 |

| Aluminium | Round Tube | 110-310 | 30-280 | 1-40 | 2.7 |

| Aluminium | Box Section | 110-310 | 30-280 | 1-40 | 2.7 |

| Aluminium | Angle | 110-310 | 30-280 | 1-40 | 2.7 |

| Aluminium | Flat Bar | 110-310 | 30-280 | 1-40 | 2.7 |

| Mild Steel | Sheet Metal | 370-700 | 215-350 | 15-25 | 7.85 |

| Mild Steel | Round Tube | 370-700 | 215-350 | 15-25 | 7.85 |

| Mild Steel | Box Section | 370-700 | 215-350 | 15-25 | 7.85 |

| Mild Steel | Angle | 370-700 | 215-350 | 15-25 | 7.85 |

| Mild Steel | Flat Bar | 370-700 | 215-350 | 15-25 | 7.85 |

| Stainless Steel | Sheet Metal | 520-1100 | 210-690 | 12-45 | 7.8 |

| Stainless Steel | Round Tube | 520-1100 | 210-690 | 12-45 | 7.8 |

| Stainless Steel | Box Section | 520-1100 | 210-690 | 12-45 | 7.8 |

| Stainless Steel | Angle | 520-1100 | 210-690 | 12-45 | 7.8 |

| Stainless Steel | Flat Bar | 520-1100 | 210-690 | 12-45 | 7.8 |

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.