- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » Cutting, Welding, and Shaping: Working with Mild Steel Round Tube

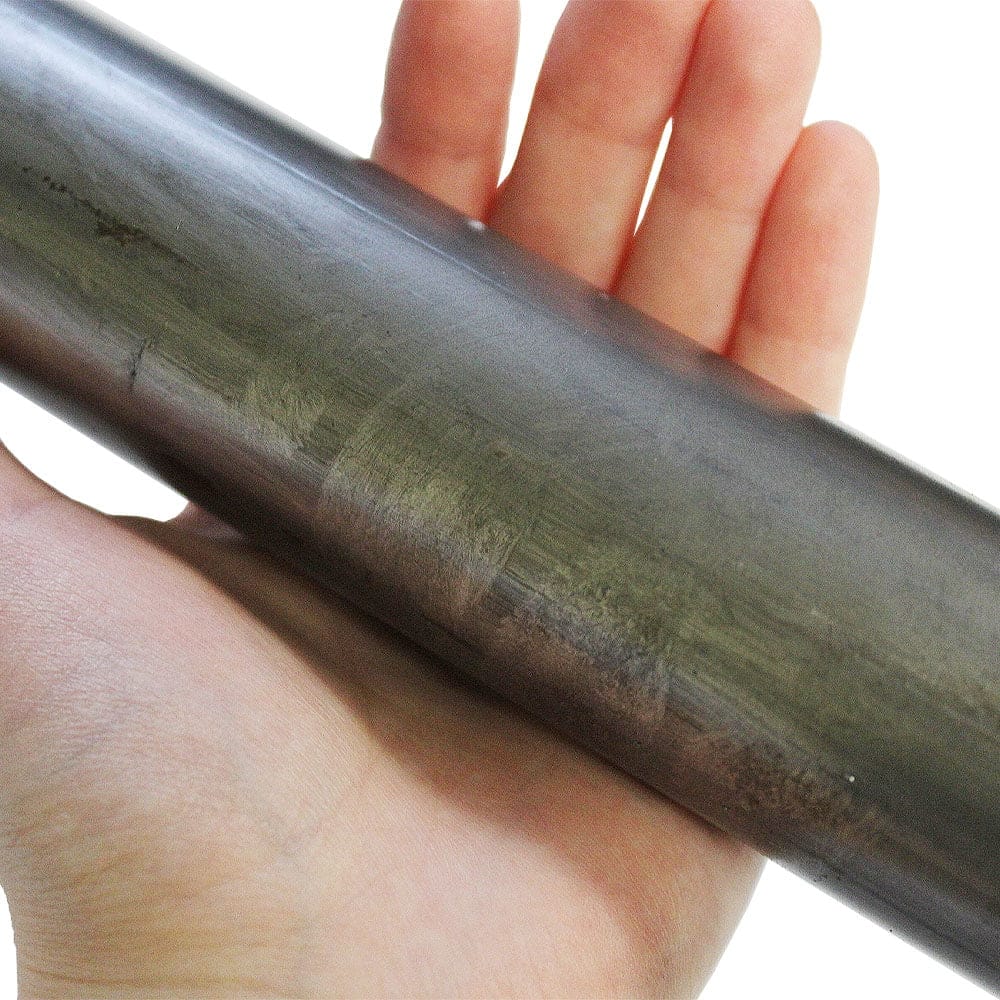

Mild steel round tubes have carved a niche in various industries owing to their unique combination of strength, malleability, and cost-effectiveness.

These attributes make them a preferred choice for artisans, engineers, and fabricators alike. The process of transforming these ubiquitous tubes into functional and aesthetic pieces involves several core techniques: cutting, welding, and shaping.

Let’s explore these foundational processes and offer insights into maximising efficiency and quality during fabrication.

Let’s get into it…….

Cutting is the initial and a crucial step in the manipulation of mild steel round tube.

The accuracy and cleanliness of the cut influence the quality of the final product. Various cutting methods exist, each offering different levels of precision, speed, and finish.

Manual Cutting: In the case of small-scale projects, hand tools such as hacksaws are often employed. Despite the fact that manual cutting is labour-intensive, it offers a high level of control, making it a suitable method for intricate custom projects.

Mechanical Cutting: In order to expedite the cutting process, power tools and machines are used. In addition to delivering fast, clean cuts, disc cutters and band saws are popular choices since they are adept at handling bulk jobs as well as delivering fast, clean cuts.

Laser and Plasma Cutting: Laser and plasma cutting technologies are unsurpassed in their ability to cut intricate designs with utmost precision. In addition, they ensure minimal waste and provide exceptionally smooth edges, reducing the amount of post-cut finishing that would otherwise be required.

Quick Tips:

There is a skill and art involved in welding that enables separate pieces of mild steel round tube to be bonded together into a unified whole. As well as the structural strength of the final piece, the quality of the weld affects the appearance of the final piece as well.

Arc Welding: Arc welding is one of the most commonly used methods for welding mild steel round tubes, since it uses an electric arc to melt the steel and fuse two pieces together as a result. Due to its simplicity and effectiveness, it has gained a great deal of popularity.

MIG Welding (Metal Inert Gas): MIG welding is a welding process which uses a wire feeding gun which not only supplies the filler material, but also emits an inert gas in order to shield the weld from contaminants that may affect the quality of the weld. In addition to its speed and adaptability, it is known for its reliability.

TIG Welding (Tungsten Inert Gas): The reason that TIG welding is chosen is because of its precision. Intricate and complex welds are especially suited for this method, which offers a cleaner finish, but requires a higher level of skill.

Quick Tips:

The process of shaping mild steel round tubes requires the use of tools and techniques that can manipulate the material without compromising its structural integrity in any way.

Bending: In order to achieve precise bends, bending machines and hydraulic presses are typically used. Choosing the right tool for bending a tube is often determined by the tube’s thickness and the radius of the bend that is desired.

Forming: The process of forming can involve a variety of processes, such as rolling, in which the tube is passed through a series of rollers to achieve the desired shape. It is particularly useful when it comes to creating curves and coils.

Machining: A number of machining processes such as turning, milling, and drilling can be used for detailed shaping works. As a result of these processes, material is removed from the tube in order to achieve intricate shapes and features.

Bullet Points:

If you want to work with mild steel round tubes, you have to master the three skills of cutting, welding, and shaping. As a result of these fundamental techniques, simple tubes can be transformed into complex structures, functional frameworks, and aesthetic pieces of art. To achieve the desired result, the key is to understand the properties of mild steel and match them with appropriate techniques and tools in order to achieve the desired result.

Safety, precision, and the material’s structural integrity should always be the highest priorities at each stage of the process. With the appropriate knowledge and tools, it is possible to fully harness the flexibility of mild steel round tubes for diverse applications across a wide range of industries by equipping oneself with the necessary knowledge and tools.

It is the combination of skill, knowledge, and technology that paves the way to exceptional results when it comes to mild steel round tubes manipulation.

Every cut, weld, and shape is a step in transforming a humble piece of pipe into an integral part of the built environment we live in today.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Please also check out the other articles in our helpful guide series. We have written about aluminium sheeting and checker plate recently to name but two of our articles.

We are also proud to sell this product on our highly popular eBay store, check us out there too.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options