- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

- Massive Range

- FREE UK Delivery

- Rapid Dispatch

Home » The Many Benefits of Brass Woven Wire Mesh

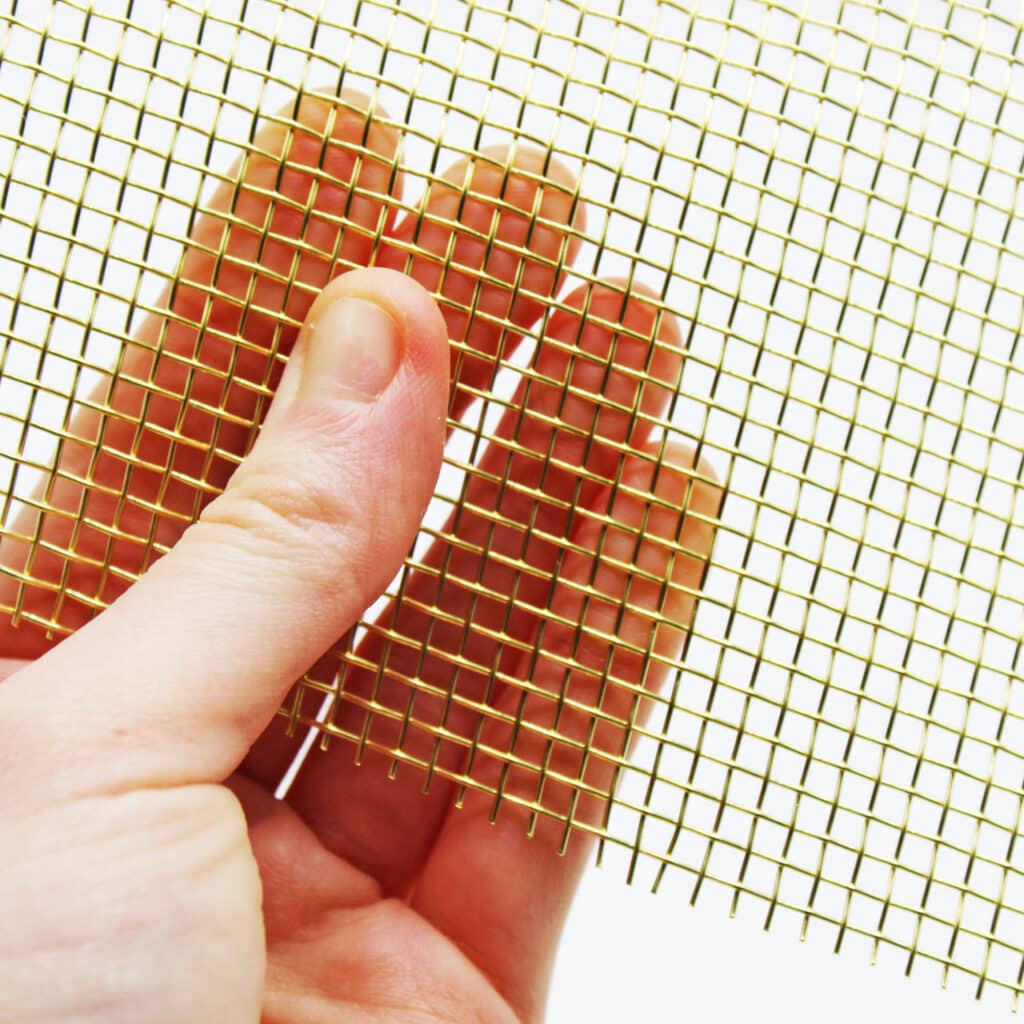

If you’ve ever been in the market for woven wire mesh, then you’ve likely encountered brass woven wire mesh. But what is it, and why is it so popular? In this blog post, we’ll discuss the benefits of brass woven wire mesh and why it’s such a good choice for many applications.

Brass woven wire mesh is a type of metal fabric made from strands of brass that are woven together. It has a wide range of uses in both industrial and decorative applications. Because of its strength and durability, brass woven wire mesh is often used in filtration systems and as a protective covering. It can also be used to make jewellery and other decorative items.

Here are a few common uses for brass woven wire mesh:

As part of our partnership with The Mesh Company we are also able to offer brass, copper, stainless steel and blue PVC wire mesh products at amazing prices.

Brass woven wire mesh has several advantages over other materials. First, it is highly resistant to corrosion, which makes it an ideal material for use in harsh environments or where there is exposure to salt water or chemicals. Additionally, because it is relatively lightweight compared to other metals like steel, brass woven wire mesh can be easily cut and shaped into various sizes and configurations without sacrificing its structural integrity. Furthermore, because of its natural beauty when polished, brass woven wire mesh can also be used as an attractive architectural element or feature on buildings or other structures.

Finally, because it is easy to work with and relatively inexpensive compared to some other types of metal fabrics, brass woven wire mesh is often chosen by architects and designers who are looking for something unique but still cost effective.

Brass wir is the perfect tool for filtration. It effectively traps larger contaminants and prevents them from entering delicate systems. Its brass composition also makes it corrosion-resistant, allowing it to serve as an effective longterm solution. Its finest mesh weaves create an incredibly tight filter that can sift out small particles, making brass woven mesh the ideal choice for filtering out even tiny particles. Versatile and time-tested, brass woven wire mesh is a great choice for any filtration application.

Brass woven wire mesh offers many benefits over other materials due to its durability, resistance to corrosion, lightweight nature, low cost point and attractive appearance when polished. Whether you need an industrial solution or something more decorative for your home or office space, this material offers a great option for any application. For those looking for a quality metal fabric with all these features combined into one product, look no further than brass woven wire mesh!

Well that about covers the main questions. We also try to answer all the questions that you may have through the product pages themselves. Look out for the FAQs section on each page.

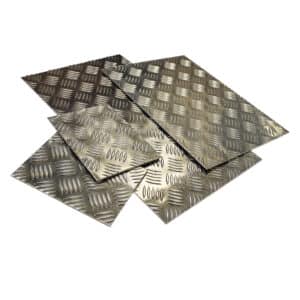

Please also check out the other articles in our helpful guide series. We have written about stainless steel woven wire mesh and checker plate recently. These articles may also help to assist you to make the right decision when selecting which metal works best for you.

If you have any further questions, feel free to contact us.

Speciality Metals

Unit 1, Farrell Street, Warrington,

Cheshire, WA1 2WW, United Kingdom

Quick Links

Payment Options